Introduction

When it comes to plumbing fittings, compression and threaded fittings are two popular types of fittings that are used to connect pipes or tubing. These fittings are essential components that are used to maintain the integrity of the pipeline. The choice of fitting you choose will impact the overall efficiency and strength of the plumbing system. This article will help you understand the difference between compression and threaded fittings.

- Compression Fittings

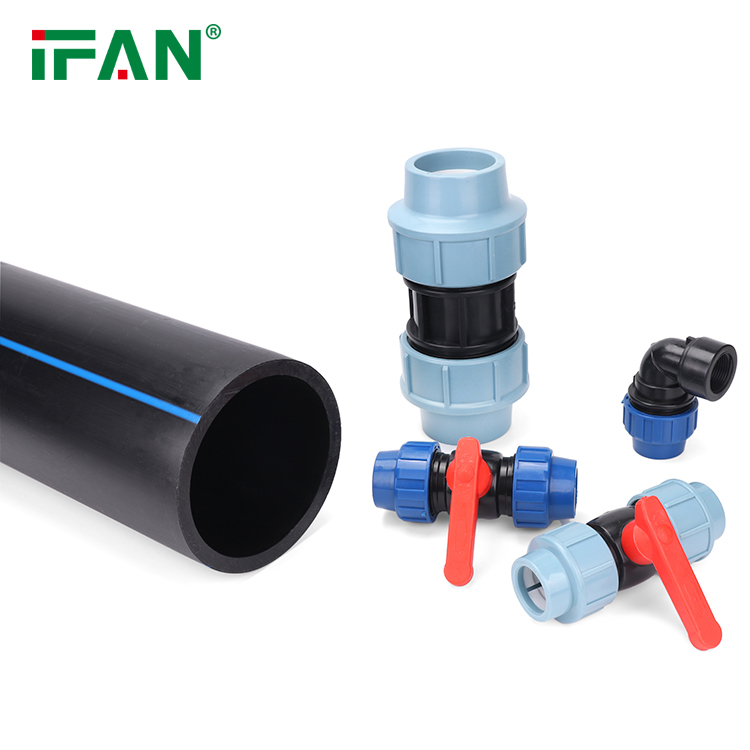

Compression fittings are commonly used to connect tubes or pipes in plumbing applications. They are easy to install and remove, which makes them popular among plumbers and DIY enthusiasts. Compression fittings are made of three components: a nut, a compression ring, and a fitting body.

- Installation of Compression Fittings

When installing compression fittings, the compression ring is placed onto the pipe and then the pipe is inserted into the fitting body. The nut is then tightened onto the fitting body which compresses the ring onto the pipe, forming a seal. Compression fittings can also be used on different materials such as plastic tubing, copper tubing, and stainless steel.

- Advantages of Compression Fittings

- Easy installation: They are easy to install and are perfect for DIY enthusiasts. Unlike other fittings, they don’t require a lot of tools or expertise to install.

- Strong: Compression fittings create a strong and leak-proof seal between the pipe and the fitting body.

- Versatile: Compression fittings can be used on different types of material such as plastic, copper, or stainless steel tubing.

- Threaded Fittings

Threaded fittings are used to connect pipes that have internal threads. They are made of two parts: the male and female threads. Pipes are commonly threaded using a pipe threader, which creates a spiral ridged pattern along the inside of the pipe. Threaded fittings are commonly used in industrial applications where high-pressure and high-temperature are required.

- Installation of Threaded Fittings

To install a threaded fitting, the male thread is screwed into the female thread until it is tight. The tightness creates a seal between the two fittings which keeps the system from leaking. One of the advantages of using a threaded fitting is that it can be easily removed and replaced if needed.

- Advantages of Threaded Fittings

- Strong: Threaded fittings are strong and can withstand high pressure and temperatures.

- Easy to install: They are easy to install and don’t require a lot of tools or expertise.

- Can be disassembled: Threaded fittings can be removed and replaced if needed.

Differences Between Compression And Threaded Fittings

- Installation: Compression fittings are easier to install since they don’t require threading machinery or a lot of tools. Threaded fittings can be more complicated, especially when dealing with larger pipes.

- Materials: Compression fittings can be used on different materials such as plastic, copper, and stainless steel. Threaded fittings require pipes to be threaded, which limits the types of materials that can be used.

- Pressure Ratings: Threaded fittings are generally used in industrial applications where high pressure and temperature ratings are required. Compression fittings are usually limited to lower pressure and temperature ratings.

- Costs: Compression fittings are generally less expensive than threaded fittings since they require fewer tools to install.

In conclusion, both compression and threaded fittings are useful in different situations. The choice of fitting you use will depend on the type of plumbing system you have and what you want to achieve. Compression fittings are easier to install and are perfect for DIY enthusiasts. Threaded fittings are better suited for industrial applications that require high pressure and temperature ratings. Regardless of which fitting you choose, it is essential to choose the correct size and material to maintain the integrity of the plumbing system.