In recent developments surrounding the delayed construction of the Perth Children’s Hospital, serious concerns have emerged regarding the use of brass fittings in the plumbing systems. The union representing workers has raised alarms about warnings that were allegedly ignored, highlighting potential risks to both the project and the safety of future patients. This article delves into the implications of these warnings, the role of brass fittings in plumbing, and the broader impact on the healthcare infrastructure in Australia.

1. Understanding Brass Fittings

1.1. What Are Brass Fittings?

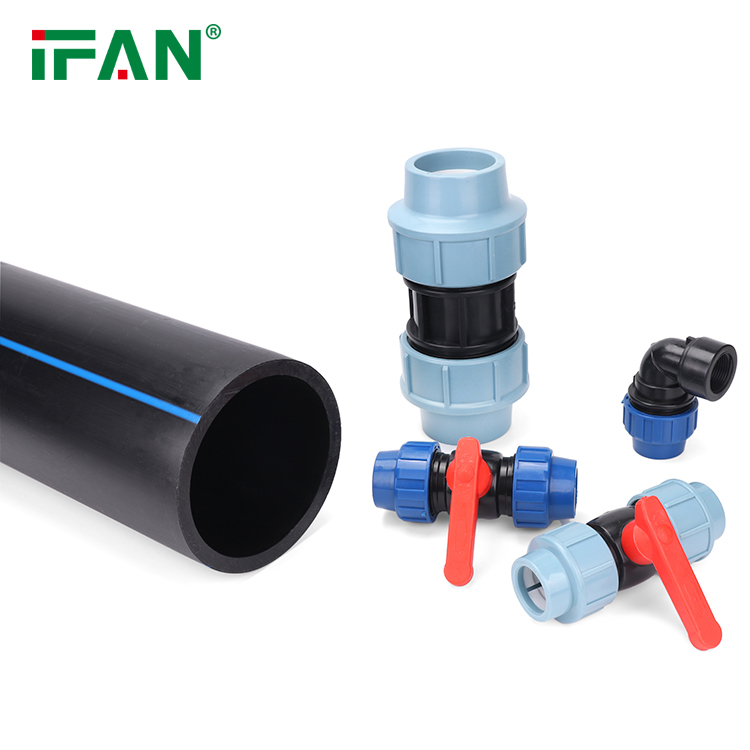

Brass fittings are essential components used in plumbing systems, crafted from an alloy of copper and zinc. They serve as connectors for pipes, valves, and fixtures, providing strength and resistance to corrosion. Common types of brass fittings include elbows, tees, couplings, and adapters, which are integral to the functionality of various plumbing systems.

1.2. Importance of Quality in Brass Fittings

The quality of brass fittings is crucial for ensuring the overall safety and performance of plumbing systems. High-quality fittings can withstand pressure and temperature fluctuations, while inferior products may lead to leaks, corrosion, and contamination. The implications of using substandard fittings are particularly concerning in sensitive environments like hospitals, where water quality is paramount.

2. The Perth Children’s Hospital Project

2.1. Background of the Project

The Perth Children’s Hospital project was initially envisioned as a state-of-the-art facility designed to provide comprehensive healthcare services to children in Western Australia. However, the project has faced multiple delays and complications, raising concerns about its timely completion and operational readiness.

2.2. Delays and Concerns

One of the significant issues contributing to the delays has been the discovery of problems related to the plumbing systems, particularly the brass fittings used throughout the facility. The union representing construction workers has voiced concerns that warnings about these fittings were overlooked, potentially compromising the integrity of the hospital’s plumbing infrastructure.

3. Union Warnings Ignored

3.1. Allegations of Ignored Warnings

According to union representatives, there were multiple instances where warnings regarding the quality and suitability of brass fittings were raised. These warnings included concerns about:

- Corrosion Resistance: Brass fittings, especially those not meeting industry standards, can corrode over time, leading to leaks and water quality issues.

- Health Risks: The presence of lead in some brass fittings can pose serious health risks, particularly in a healthcare setting where vulnerable populations, such as children, are treated.

3.2. The Union’s Stance

The union has emphasized that ignoring these warnings not only jeopardizes the construction timeline but also places future patients at risk. They argue that the safety of the hospital’s plumbing should be a top priority, and any concerns regarding the materials used must be thoroughly investigated and addressed.

4. The Role of Brass Fittings in Plumbing Systems

4.1. Types of Brass Fittings Used

In plumbing systems, various types of brass fittings are utilized, including:

- Elbows: Used to change the direction of piping.

- Tees: Allow for branching off to another pipe.

- Couplings: Connect two lengths of pipe.

- Adapters: Facilitate the connection of different types of pipes or fixtures.

4.2. Standards and Regulations

To ensure the safety and reliability of brass fittings, manufacturers must adhere to strict industry standards and regulations. In Australia, these standards are enforced by organizations such as Standards Australia and the Australian Building Codes Board. Compliance with these regulations is crucial, especially in healthcare settings where water quality is critical.

5. Implications for Healthcare Infrastructure

5.1. Impact on Patient Safety

The potential use of substandard brass fittings in the Perth Children’s Hospital raises serious concerns about patient safety. Corroded or defective fittings can lead to leaks and contamination, posing health risks to children receiving treatment. Ensuring the integrity of plumbing systems in hospitals is essential for maintaining a safe environment for patients.

5.2. Broader Consequences for Healthcare Projects

The situation at the Perth Children’s Hospital serves as a cautionary tale for other healthcare projects across Australia. It highlights the importance of rigorous quality control and adherence to safety standards in construction. Future projects must prioritize the use of high-quality materials to prevent similar issues and ensure the safety of all patients.

6. Moving Forward: Addressing the Concerns

6.1. Investigating the Issues

In light of the warnings raised by the union, it is imperative for the relevant authorities and stakeholders to conduct a thorough investigation into the use of brass fittings in the Perth Children’s Hospital. This investigation should include:

- Material Testing: Assessing the quality and safety of the brass fittings used in the project.

- Compliance Review: Ensuring that all materials meet the required industry standards and regulations.