In recent years, the plumbing industry has faced significant scrutiny regarding the safety and quality of its products, particularly brass fittings. A notable case is the Uponor brass fitting class action settlement, which has raised awareness about the potential risks associated with these fittings and their impact on consumers. This article delves into the details of the settlement, the implications for consumers, and the broader context of brass fittings in plumbing systems.

Understanding Brass Fittings

1. What Are Brass Fittings?

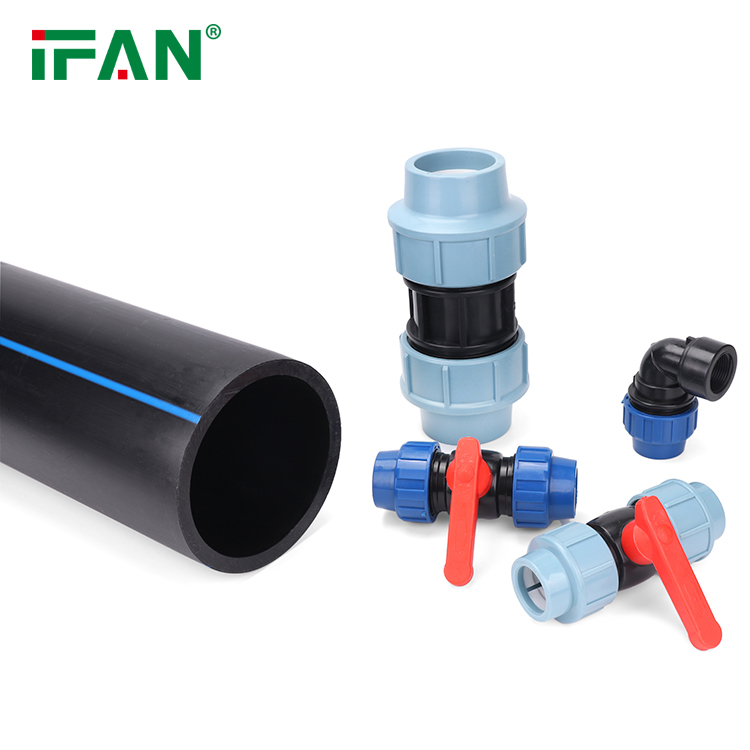

Brass fittings are essential components used in plumbing systems, designed to connect pipes and facilitate the flow of water and other fluids. Made primarily from an alloy of copper and zinc, brass fittings are favored for their durability, corrosion resistance, and ability to withstand high pressures. Common types of brass fittings include elbows, tees, couplings, and valves.

2. Importance of Quality in Brass Fittings

The quality of brass fittings is crucial for ensuring the safety and reliability of plumbing systems. Poor-quality fittings can lead to leaks, corrosion, and even contamination of drinking water. Therefore, manufacturers must adhere to strict safety standards and regulations to protect consumers.

The Uponor Brass Fitting Class Action Settlement

1. Background of the Class Action

The class action lawsuit against Uponor was initiated by consumers who alleged that the company’s brass fittings contained harmful levels of lead. Lead exposure can pose serious health risks, particularly for children and pregnant women. The lawsuit claimed that Uponor failed to adequately warn consumers about the potential dangers associated with its products.

2. Key Details of the Settlement

In response to the lawsuit, Uponor agreed to a settlement that includes several key components:

- Financial Compensation: A fund was established to provide financial compensation to affected consumers who purchased the faulty brass fittings.

- Product Recall: Affected products were recalled to prevent further sales and usage.

- Improved Safety Measures: Uponor committed to implementing stricter quality control measures to ensure that future products meet safety standards.

3. Implications for Consumers

The settlement has significant implications for consumers:

- Increased Awareness: The case has raised awareness about the potential risks associated with brass fittings, prompting consumers to be more vigilant in their purchasing decisions.

- Consumer Protection: The settlement underscores the importance of consumer protection laws and the role of legal action in holding manufacturers accountable for their products.

- Future Purchases: Consumers may become more cautious when purchasing brass fittings, opting for products from manufacturers with a proven track record of safety and quality.

The Role of Lead in Brass Fittings

1. Understanding Lead Contamination

Lead is a toxic metal that can leach into drinking water through corroded pipes and fittings. Prolonged exposure to lead can lead to serious health issues, including developmental delays in children, cognitive impairments, and various physical health problems.

2. Regulations and Standards

In response to the dangers of lead contamination, regulatory bodies such as the Environmental Protection Agency (EPA) and the American National Standards Institute (ANSI) have established strict guidelines for the acceptable levels of lead in plumbing products. Manufacturers are required to comply with these standards to ensure the safety of their products.

The Importance of Quality Control in Manufacturing

1. Quality Control Measures

To prevent issues like those seen in the Uponor case, manufacturers must implement rigorous quality control measures throughout the production process. This includes:

- Material Testing: Regular testing of raw materials to ensure they meet safety standards.

- Production Oversight: Continuous monitoring of the manufacturing process to detect any deviations from quality standards.

- Final Inspections: Comprehensive inspections of finished products before they are released to the market.

2. Consumer Trust and Brand Reputation

Quality control is not only vital for safety but also for maintaining consumer trust and brand reputation. Companies that prioritize quality are more likely to build a loyal customer base and avoid legal issues related to product safety.

The Future of Brass Fittings

1. Innovations in Materials

The plumbing industry is evolving, with manufacturers exploring alternative materials that offer similar benefits to brass fittings without the associated risks. Innovations may include:

- Lead-Free Alloys: Development of new alloys that do not contain lead, reducing the risk of contamination.

- Advanced Coatings: Application of protective coatings to prevent corrosion and extend the lifespan of fittings.

2. Sustainability Considerations

As environmental concerns continue to grow, the plumbing industry is also focusing on sustainability. This includes:

- Recycling Programs: Initiatives to recycle old brass fittings and reduce waste.

- Eco-Friendly Practices: Adoption of manufacturing processes that minimize environmental impact.

Conclusion

The Uponor brass fitting class action settlement serves as a critical reminder of the importance of safety and quality in plumbing products. As consumers become more informed about the risks associated with brass fittings, manufacturers must prioritize quality control and adhere to safety regulations to regain trust and ensure public health. The future of