Introduction

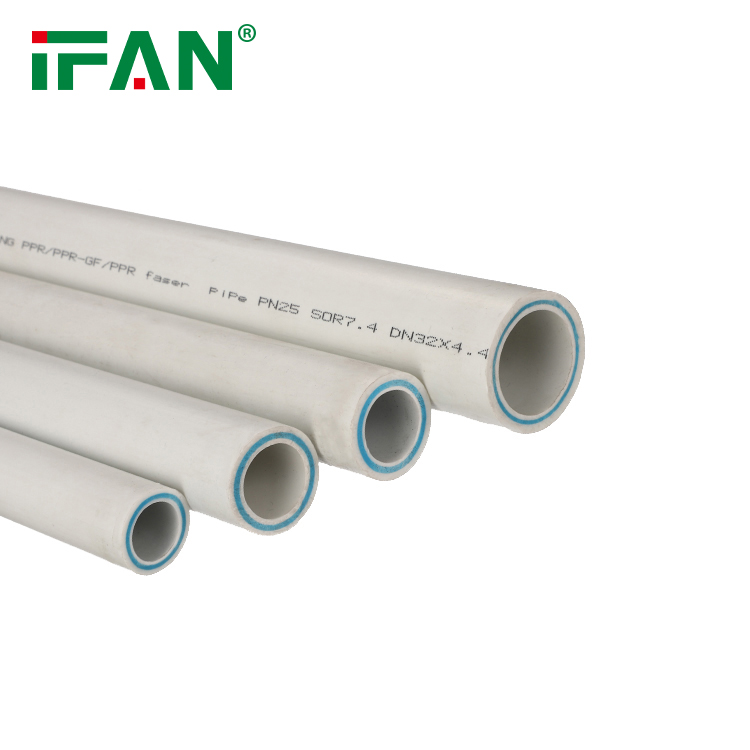

PPR (Polypropylene Random Copolymer) fiberglass pipes play a crucial role in heating systems, providing numerous benefits and ensuring efficient and reliable heat distribution. In this article, we will explore the key reasons why PPR fiberglass pipes are widely used in heating systems. Let’s break down each section into separate headings.

1. Excellent Thermal Insulation

One of the primary advantages of PPR fiberglass pipes in heating systems is their excellent thermal insulation properties. These pipes are designed to minimize heat loss during the transportation of hot water. The fiberglass layer incorporated into the pipe construction acts as a barrier, preventing heat from escaping into the surrounding environment. This insulation ensures that the heat produced by the heating system is efficiently delivered to the desired areas, promoting energy efficiency and reducing heating costs.

2. Resistance to High Temperatures

PPR fiberglass pipes are specifically engineered to withstand high temperatures commonly associated with heating systems. They can safely transport hot water without the risk of deformation, degradation, or loss of structural integrity. The ability of PPR fiberglass pipes to handle high temperatures ensures the safe and efficient operation of heating systems, preventing any potential hazards or system failures.

3. Corrosion and Chemical Resistance

Heating systems often involve the use of chemicals, such as corrosion inhibitors or anti-freeze agents, to ensure the longevity and performance of the system. PPR fiberglass pipes exhibit high resistance to corrosion and various chemicals, including those commonly used in heating systems. This resistance minimizes the risk of pipe degradation, ensuring the longevity and reliability of the heating system. Additionally, it helps maintain the purity of the hot water, preventing any chemical contamination that could affect the performance or quality of the heat distribution.

4. Low Thermal Expansion

PPR fiberglass pipes have a low coefficient of thermal expansion, meaning they expand and contract minimally with changes in temperature. This characteristic is crucial in heating systems, where temperature differentials can be significant. The low thermal expansion of PPR fiberglass pipes reduces the stress on the system, minimizing the risk of leaks, cracks, or joint failures. It ensures the integrity and stability of the heating system, allowing for consistent and reliable heat distribution.

5. Easy Installation and Maintenance

PPR fiberglass pipes are lightweight, flexible, and easy to install, making them a preferred choice for heating systems. Their flexibility allows for convenient routing and installation in tight spaces, reducing the need for complex and costly modifications. Additionally, the smooth inner surface of PPR fiberglass pipes minimizes pressure drops and sediment accumulation, simplifying maintenance and reducing the risk of system inefficiencies or blockages.

6. Long Lifespan

PPR fiberglass pipes exhibit excellent durability and have a long lifespan compared to many other piping materials. The combination of fiberglass reinforcement and high-quality polypropylene ensures the pipes’ resistance to impact, wear, and degradation over time. The prolonged lifespan of PPR fiberglass pipes translates to reduced maintenance and replacement costs, contributing to the overall economic viability and sustainability of heating systems.

Conclusion

PPR fiberglass pipes play a critical role in heating systems, offering excellent thermal insulation, resistance to high temperatures and corrosion, low thermal expansion, easy installation and maintenance, and a long lifespan. These pipes ensure efficient heat distribution, promote energy efficiency, and contribute to the longevity and reliability of heating systems. By utilizing PPR fiberglass pipes, heating systems can provide comfortable and consistent heat while minimizing operational costs and environmental impact.