Introduction to HDPE Pipes and Fittings

HDPE (High-Density Polyethylene) pipes and fittings have emerged as a key component in various industries, offering unparalleled durability, flexibility, and cost-efficiency. This comprehensive guide explores the benefits, applications, and latest trends in HDPE pipe and fitting technology.

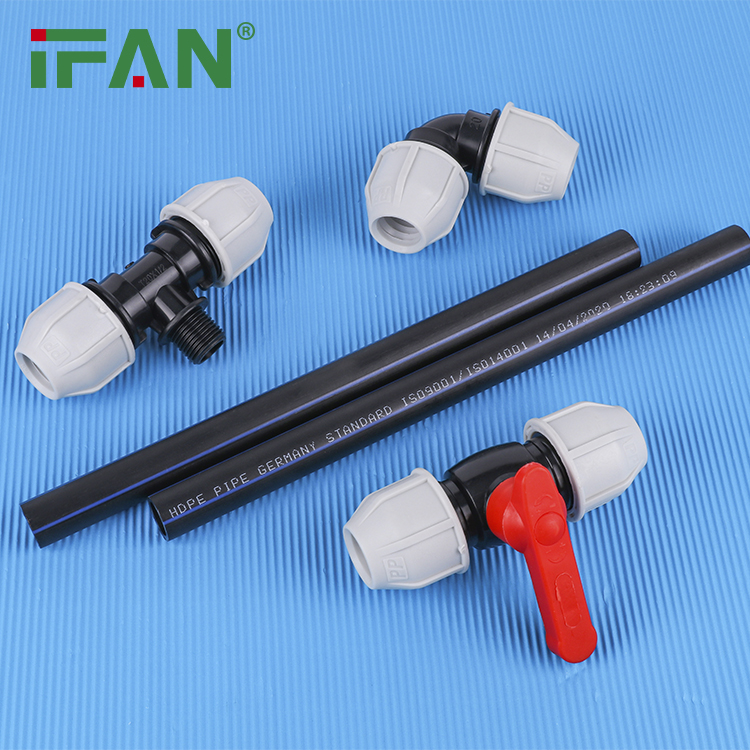

What Are HDPE Pipes and Fittings?

HDPE pipes are made from high-density polyethylene, a thermoplastic material with exceptional strength and chemical resistance. HDPE fittings, meanwhile, are specialized components that facilitate the connection of HDPE pipes, ensuring a secure and leak-free system.

Key Benefits of HDPE Pipes and Fittings

- Durability: HDPE pipes and fittings are renowned for their durability, resisting corrosion, abrasion, and chemical attack. This ensures a long service life and reduced need for maintenance.

- Flexibility: HDPE’s thermoplastic properties allow for pipes to be bent and manipulated into various configurations, simplifying installation in complex environments.

- Cost-Efficiency: HDPE pipes and fittings are cost-effective solutions, offering lower installation costs compared to traditional materials such as steel or concrete.

Applications of HDPE Pipes and Fittings

- Water and Wastewater Systems: HDPE pipes and fittings are widely used in water and wastewater distribution systems, providing a reliable and leak-free infrastructure.

- Oil and Gas Transportation: HDPE’s chemical resistance and durability make it a suitable choice for oil and gas pipelines, ensuring the safe and efficient transportation of hydrocarbons.

- Irrigation Systems: HDPE pipes are a popular choice for agricultural irrigation systems, as they are lightweight, easy to install, and resistant to corrosion.

Latest Trends in HDPE Pipe and Fitting Technology

- Advancements in Material Science: Research is continually being conducted to enhance the performance of HDPE materials, resulting in improved strength, flexibility, and chemical resistance.

- Innovations in Fitting Design: Manufacturers are introducing new fitting designs that offer faster installation, enhanced reliability, and reduced leakage risks.

- Sustainability Focus: With increasing emphasis on environmental sustainability, HDPE pipes and fittings are being recognized for their recyclability and reduced environmental impact.

Conclusion

HDPE pipes and fittings have revolutionized the piping industry, offering a reliable, cost-effective, and environmentally friendly solution for various applications. As technology continues to evolve, HDPE’s potential is only set to grow, making it a crucial component in the future of piping infrastructure.