Description

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

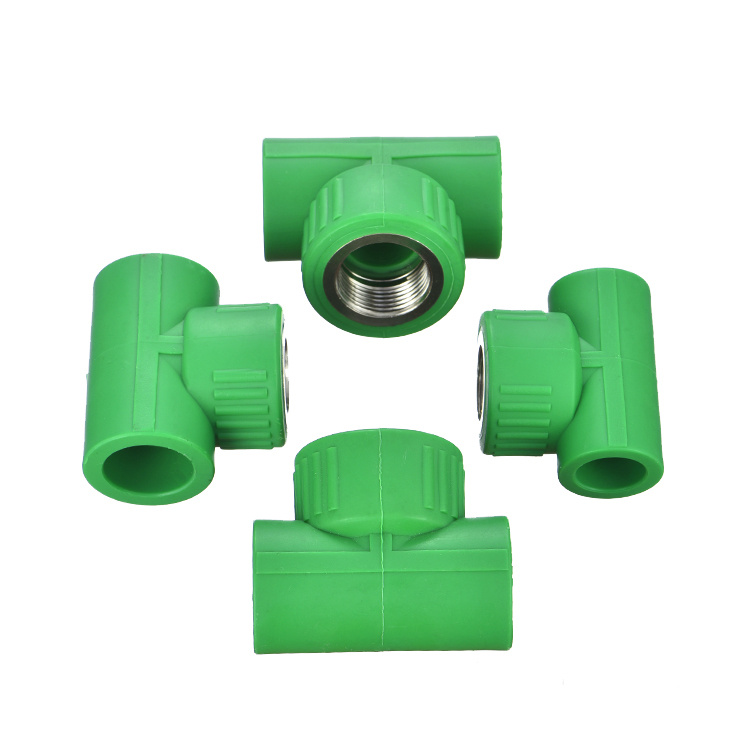

Introduction to Leak-Free PPR Fitting Installation

Ensuring a leak-free installation of PPR (Polypropylene Random Copolymer) fittings is crucial for maintaining a reliable and efficient plumbing system. Proper installation techniques prevent leaks, which can lead to costly repairs and water damage. This guide provides essential tips for achieving a secure, leak-free installation of PPR fittings, covering preparation, installation, testing, and maintenance.

Preparation and Planning

Effective preparation is key to a successful PPR fitting installation. Begin by gathering all necessary tools and materials, including PPR fittings, pipes, a pipe cutter, a deburring tool, and a heat source for fusion welding. It’s important to measure and cut the PPR pipes accurately to ensure a snug fit with the fittings. Additionally, clean and dry the surfaces to be joined thoroughly to remove any debris or moisture, which can interfere with the fusion process. Planning your installation layout carefully and checking that all components are compatible will prevent potential issues during the installation.

Proper Fusion Technique

The fusion process is critical for creating a leak-free connection between PPR fittings and pipes. Use a PPR fusion machine to heat the pipe ends and fittings to the correct temperature. Typically, this temperature is around 260°C (500°F), but always refer to the manufacturer’s specifications. Ensure that the heating time is consistent and that the pipe and fitting are heated evenly to avoid weak joints. Once heated, quickly join the pipe and fitting together, maintaining pressure for the recommended cooling period. This method ensures a strong, homogeneous bond that minimizes the risk of leaks.

Inspecting and Testing Connections

After installation, inspecting and testing the connections is essential to confirm that they are leak-free. Visually inspect each joint to ensure there are no visible gaps or irregularities. Conduct a pressure test by gradually increasing the water pressure in the system to its maximum working pressure, then check for leaks at all joints and connections. If possible, use a pressure gauge to monitor and confirm that the system holds pressure without any drop. Address any leaks immediately by re-fusing or replacing the faulty fittings.

Maintenance and Regular Checks

Regular maintenance and checks are vital for ensuring the long-term reliability of PPR fittings. Periodically inspect the plumbing system for signs of wear or damage, especially in areas prone to stress or movement. Avoid exposing PPR fittings to extreme temperatures or harsh chemicals, as these can weaken the fittings over time. Ensure that the system is protected from freezing temperatures, as PPR fittings, while resistant to freezing, can still be affected by extreme conditions. Addressing minor issues promptly can prevent them from developing into significant problems.

Conclusion

Achieving a leak-free PPR fitting installation requires meticulous preparation, proper fusion techniques, thorough inspection, and regular maintenance. By following these guidelines, you can ensure that your PPR fittings provide a secure and reliable connection, minimizing the risk of leaks and ensuring the efficiency of your plumbing system. Proper installation and maintenance not only extend the lifespan of the fittings but also contribute to the overall performance and safety of the plumbing infrastructure.

Related products

-

PPR Fittings

PPR Material Pipe Fittings

-

PPR Fittings

IFAN PPR Fittings