Description

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

When it comes to selecting the right valve for your piping system, the choice between full-port and standard-port brass ball valves is an important decision. Brass ball valves are a popular choice in various industries due to their reliability, durability, and versatility. However, understanding the differences between full-port and standard-port ball valves is crucial for ensuring optimal performance and system efficiency. In this article, we’ll guide you through the factors to consider when choosing between these two types of brass ball valves.

What is a Brass Ball Valve?

A brass ball valve is a type of valve that uses a ball with a hole in the center to control the flow of liquids or gases through a pipe. The ball rotates within the valve body, allowing or blocking the flow depending on its position. Brass ball valves are known for their corrosion resistance, making them ideal for applications involving water, gas, and other fluids.

Full-Port vs. Standard-Port Brass Ball Valves

The key difference between full-port and standard-port brass ball valves lies in the internal diameter of the valve body and how it relates to the pipe size.

1. Full-Port Brass Ball Valve:

A full-port brass ball valve has an internal diameter that is the same size as the pipe it is connected to. This means the flow path through the valve is unobstructed, allowing for maximum flow capacity. Full-port valves are designed to minimize pressure loss and flow restrictions, making them ideal for high-flow applications.

2. Standard-Port Brass Ball Valve:

In contrast, a standard-port brass ball valve has a slightly smaller internal diameter than the pipe it is connected to. This results in a narrower flow path, which can cause slight pressure drops and reduced flow capacity compared to a full-port valve. However, standard-port valves are still suitable for many general applications where maximum flow is not a primary concern.

Factors to Consider When Choosing Between Full-Port and Standard-Port Brass Ball Valves

1. Flow Requirements

The most significant factor in choosing between full-port and standard-port brass ball valves is the flow requirements of your system. If your system requires high flow rates, minimal pressure loss, or is dealing with thick liquids or slurries, a full-port brass ball valve will provide the best performance. It ensures that the flow path remains wide open, minimizing restrictions.

On the other hand, if your system doesn’t require high flow rates and is mainly used for regulating flow rather than maximizing it, a standard-port brass ball valve may be sufficient. These valves are often more cost-effective and work well in many general applications.

2. Pressure Loss

Pressure loss is a critical consideration in any piping system. Full-port brass ball valves are designed to minimize pressure loss due to their unobstructed flow path. This makes them suitable for systems where maintaining pressure is crucial. Standard-port valves, while effective, can cause slight pressure drop due to their smaller internal diameter.

In systems where pressure drop is a concern—such as in water supply, HVAC systems, or industrial applications—a full-port brass ball valve is typically the better choice.

3. Cost

Cost is often a deciding factor in valve selection. Full-port brass ball valves are generally more expensive than standard-port valves due to their larger internal diameter and more advanced design. While the price difference may be minimal for small systems, it can add up for large-scale applications or when multiple valves are needed.

If you don’t require the high flow capacity and minimal pressure loss that a full-port valve offers, opting for a standard-port brass ball valve can save you money without sacrificing too much performance.

4. Size of the Piping System

The size of the piping system is another important consideration when choosing between full-port and standard-port brass ball valves. For smaller piping systems, the difference in flow capacity between full-port and standard-port valves may be negligible. However, for larger systems with high flow demands or those with a significant number of valves, the benefits of a full-port valve become more apparent.

5. Application Type

Brass ball valves are used in a variety of applications, including water systems, gas pipelines, and HVAC systems. The specific requirements of your application will also dictate the best choice of valve.

– For industrial applications involving high-flow liquids or gases, full-port brass ball valves are often necessary to avoid flow restrictions and pressure drops.

– For residential or commercial plumbing systems, a standard-port valve may suffice, especially for regulating flow in systems with low to moderate flow rates.

6. Maintenance Considerations

Both full-port and standard-port brass ball valves are relatively low-maintenance, but the full-port variety may require slightly more care due to its larger internal size. Ensuring that these valves are correctly sized and installed will help prevent potential maintenance issues related to flow restrictions or pressure drops.

Advantages of Full-Port Brass Ball Valves

– Maximum Flow Capacity: Full-port valves provide unrestricted flow, which is ideal for high-flow systems.

– Minimal Pressure Drop: Due to the full-flow design, there is less resistance to flow, resulting in lower pressure loss.

– Ideal for Large Applications: Full-port valves are excellent choices for large-scale industrial and commercial systems.

Advantages of Standard-Port Brass Ball Valves

– Cost-Effective: Standard-port valves are generally less expensive than full-port valves.

– Compact Size: The smaller internal diameter makes these valves more compact, ideal for space-constrained applications.

– Suitable for General Use: Perfect for systems that don’t require high flow rates or minimal pressure loss.

Conclusion

Choosing between a full-port and standard-port brass ball valve ultimately depends on the specific needs of your system. If high flow capacity and minimal pressure loss are critical, a full-port valve is the best option. On the other hand, if cost is a primary concern and your system can tolerate some pressure drop, a standard-port valve is a suitable and cost-effective choice.

By understanding the distinct characteristics and applications of full-port and standard-port brass ball valves, you can make an informed decision that ensures efficiency, durability, and optimal performance in your piping system.

FAQs

1. What’s the difference between full-port and standard-port brass ball valves?

A full-port brass ball valve has an internal diameter the same size as the pipe, providing unobstructed flow, while a standard-port valve has a smaller diameter, leading to a slight reduction in flow.

2. Are full-port brass ball valves more expensive than standard-port valves?

Yes, full-port brass ball valves are generally more expensive due to their design, which allows for higher flow capacity and reduced pressure loss.

3. When should I use a full-port brass ball valve?

Full-port brass ball valves are ideal for high-flow applications, systems requiring minimal pressure drop, and industrial systems where maximum flow capacity is essential.

4. Can I use a standard-port brass ball valve in residential plumbing systems?

Yes, standard-port brass ball valves are commonly used in residential and commercial plumbing systems, as they work well in systems with moderate flow rates.

5. How can I maintain a brass ball valve?

To maintain a brass ball valve, ensure it is properly installed, free from debris, and regularly inspected for signs of wear or corrosion. Lubricating the valve stem can also prevent wear and ensure smooth operation.

Related products

-

Ball Valve

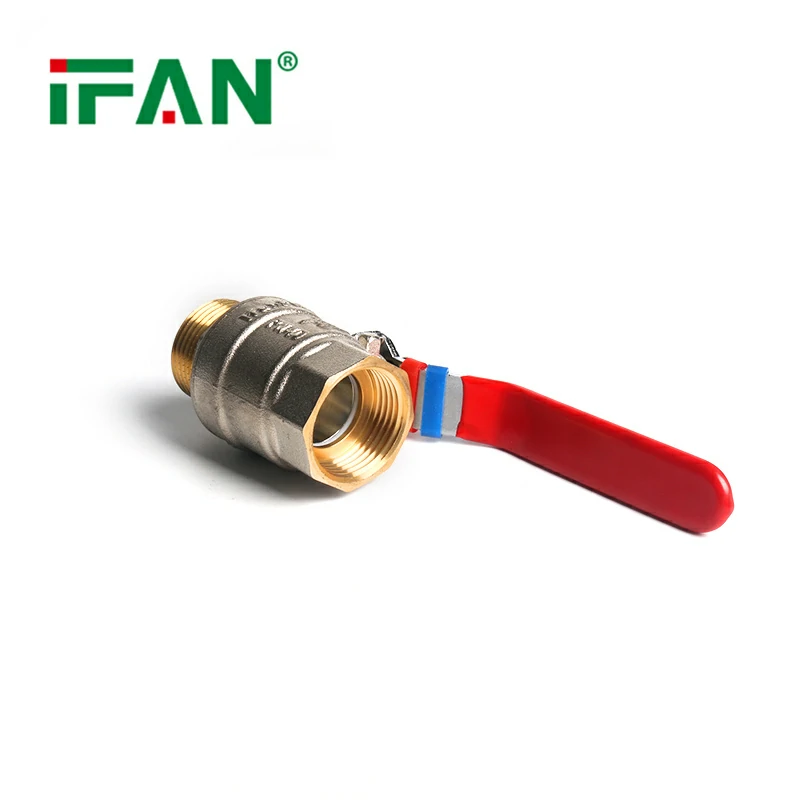

Male Thread Brass Ball Valve

-

Ball Valve

Brass Ball Valve

-

Ball Valve

IFAN Brass Ball Valve 81053

-

Ball Valve

Brass Ball Valve