Description

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

PPR fittings (Polypropylene Random Copolymer fittings) have gained popularity in the plumbing industry due to their durability, corrosion resistance, and eco-friendly properties. However, ensuring leak-free connections is crucial for maintaining the effectiveness of a PPR piping system. In this article, we will explore how to achieve reliable, leak-free connections using PPR fittings, along with essential tips and techniques to prevent leaks in your plumbing system.

1. Understanding the Basics of PPR Fittings

Before diving into the methods of ensuring leak-free connections, it’s important to understand what PPR fittings are and how they work. PPR fittings are made from a type of polypropylene plastic that is both durable and resistant to high temperatures and pressure. These fittings are commonly used in residential and commercial plumbing systems for hot and cold water supply, as well as heating systems.

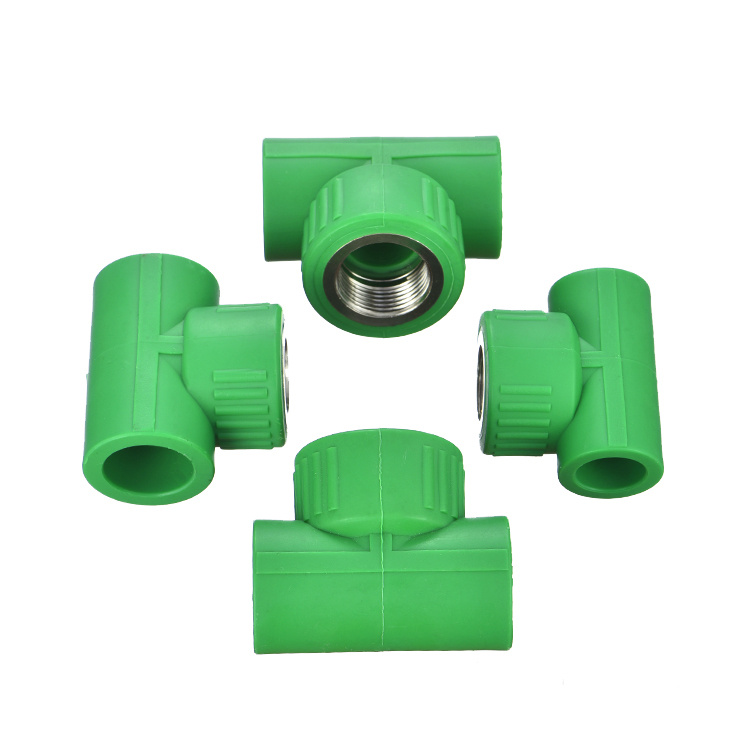

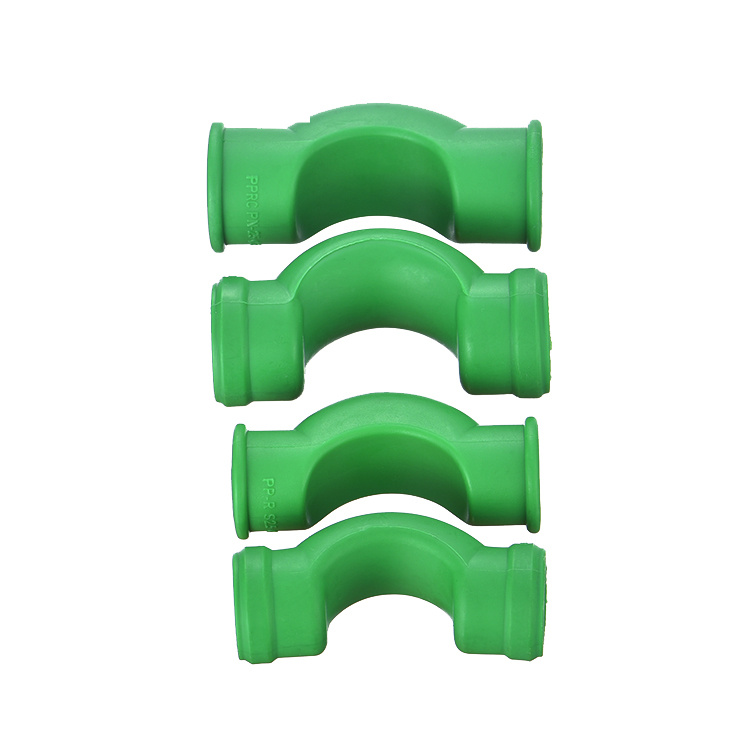

PPR fittings come in various shapes, sizes, and designs, including elbow joints, tees, couplings, and end caps. They are known for their easy installation process, as they can be fused or welded together, creating strong and secure connections.

2. The Importance of Proper Installation

The key to preventing leaks in PPR fittings is proper installation. A poorly installed fitting can lead to water leakage, weakening the integrity of the entire plumbing system. Follow these steps to ensure a leak-free connection:

a) Cut the PPR Pipe Properly

Start by cutting the PPR pipe cleanly and accurately. The cut should be straight and smooth, ensuring that there are no jagged edges or burrs that could prevent the fitting from sealing properly. Use a specialized pipe cutter to make a precise cut, and avoid using saws or knives, as these tools can leave rough edges.

b) Deburr the Pipe Edges

After cutting the pipe, deburr the edges to remove any sharp or uneven edges. This will help create a smoother surface for the fitting to connect to, ensuring a better seal. Use a deburring tool or a knife to carefully smooth out the edges of the pipe.

c) Ensure the Pipe Is Clean and Dry

Before installing the fitting, make sure both the pipe and the inside of the fitting are clean and dry. Any dirt, dust, or moisture can interfere with the fusion process, leading to poor bonding and potential leaks. Wipe the pipe and fitting with a clean cloth to remove any contaminants.

3. Fusion Process: The Key to Leak-Free Connections

The most effective method for joining PPR fittings is the fusion process. This involves heating the pipe and fitting until they reach a specific temperature, at which point they are fused together to form a permanent, leak-proof connection. Here’s how to properly perform the fusion process:

a) Use a Properly Calibrated Fusion Tool

To achieve a strong fusion, use a high-quality fusion tool that is designed for PPR pipe installation. The tool should be calibrated to the correct temperature, typically between 260°F and 280°F (130°C and 138°C), depending on the manufacturer’s specifications. Ensure that the fusion tool is in good condition and free of defects to guarantee a secure bond.

b) Heat the Pipe and Fitting Evenly

Place the pipe and fitting onto the fusion tool’s heating plates. Ensure that both the pipe and fitting are heated evenly, so that the fusion occurs uniformly. Allow them to heat for the specified amount of time—usually between 10 and 30 seconds—depending on the size of the pipe and fitting.

c) Join the Pipe and Fitting Quickly

Once the pipe and fitting have reached the desired temperature, quickly remove them from the heating plates and immediately push the pipe into the fitting, ensuring they are aligned properly. Hold them together for a few seconds to allow the fusion process to complete. The pipe and fitting should remain in place until they cool down and harden, creating a strong, leak-free bond.

4Check the Connection for Leaks

After the fusion process is complete, it’s essential to inspect the connection for any signs of leakage. Here are some steps to check for leaks:

a) Perform a Pressure Test

One of the most effective ways to ensure a leak-free connection is to perform a pressure test. Fill the plumbing system with water and gradually increase the pressure to the required level. Monitor the system for any drops in pressure, which could indicate a leak. If the pressure remains steady, the connection is secure.

b) Inspect Visually for Leaks

Inspect the area around the fitting for any signs of water droplets or moisture, which could suggest a small leak. If any moisture is visible, you may need to reheat and rejoin the fitting to ensure a better bond.

5. Additional Tips for Preventing Leaks in PPR Fittings

While proper installation and fusion are key to preventing leaks, here are a few additional tips to ensure leak-free connections:

a) Avoid Over-tightening the Fittings

When installing PPR fittings, it’s important not to over-tighten them, as this can damage the pipe or the fitting, leading to leaks. Tighten the fittings just enough to create a secure connection, without excessive force.

b) Use High-Quality Fittings and Pipes

Always use high-quality PPR fittings and pipes that meet industry standards. Inferior-quality materials may not fuse properly, resulting in weak connections that are prone to leaks.

c) Follow Manufacturer Instructions

Each manufacturer may have slightly different recommendations for fusion times, temperatures, and installation methods. Always refer to the manufacturer’s instructions for the specific PPR fittings you are using to ensure the best results.

d) Use Pipe Insulation

In areas where temperatures fluctuate dramatically, consider using pipe insulation to protect the PPR fittings from extreme heat or cold. This can help prevent thermal expansion or contraction, which could lead to leaks over time.

6. Regular Maintenance and Inspections

Even after installation, it’s important to regularly inspect your plumbing system for signs of leaks. Periodically check connections for any changes in water pressure, unusual moisture, or other indicators of leaks. Routine maintenance can help detect small issues before they become major problems.

Conclusion

Ensuring leak-free connections with PPR fittings requires proper preparation, installation, and maintenance. By following the correct fusion procedures, using high-quality materials, and performing regular inspections, you can create a secure and reliable plumbing system that will last for years to come. With these best practices, you’ll be able to prevent leaks and ensure that your plumbing system functions effectively and efficiently.

Frequently Asked Questions (FAQs)

1. What are PPR fittings made of?

PPR fittings are made of polypropylene random copolymer (PPR), a durable plastic that is resistant to high temperatures and pressure, making it ideal for plumbing systems.

2. How do you fuse PPR fittings together?

PPR fittings are fused using a heat fusion process, where both the pipe and fitting are heated to a specific temperature and then pressed together to form a strong, permanent bond.

3. Can PPR fittings be used for hot water plumbing?

Yes, PPR fittings are designed to withstand high temperatures, making them suitable for both hot and cold water plumbing systems.

4. How do I ensure a leak-free connection with PPR fittings?

To ensure a leak-free connection, properly cut, deburr, and clean the pipe and fitting before fusing them using a high-quality fusion tool. Follow the manufacturer’s instructions for temperature and fusion times.

5. How often should I inspect my PPR fittings?

It’s recommended to inspect your PPR fittings periodically for signs of leaks or wear, especially in systems that are subject to high water pressure or temperature fluctuations.

Related products

-

PPR Fittings

PPR Material Pipe Fittings

-

PPR Fittings

PPR Pipe and Fittings

-

PPR Fittings

What is the PPR Fittings