Description

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

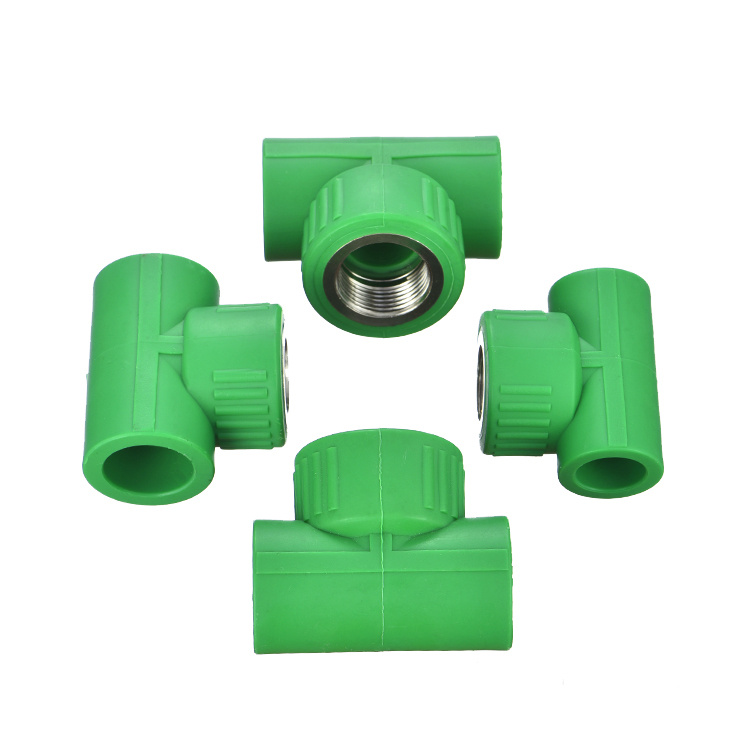

Introduction to PPR Fittings

Polypropylene Random Copolymer (PPR) fittings are widely recognized for their versatility, durability, and ease of installation in plumbing and heating systems. This guide explores essential considerations for both installing and maintaining PPR fittings, ensuring optimal performance and longevity in various applications.

Choosing the Right PPR Fittings

Selecting the appropriate PPR fittings is crucial to the success of any plumbing project. Fittings are available in a range of types, including elbows, tees, couplings, and adapters, each designed for specific purposes such as direction changes, branch connections, or transitions between different pipe sizes. It’s essential to match the fitting type with the intended application and pipe diameter to ensure compatibility and efficiency in the system.

Installation Procedures

The installation of PPR fittings follows a systematic approach to guarantee reliability and prevent leaks. Begin by carefully measuring and cutting the PPR pipes to required lengths, ensuring clean, square cuts. Prepare the pipe ends and fittings by removing burrs and ensuring they are dry and free from dust or contaminants. Heat fusion, the primary method for joining PPR fittings, involves heating both the pipe and fitting ends uniformly using a specialized fusion tool until they reach the prescribed fusion temperature. Once heated, quickly join the components and hold them steady until the joint cools and solidifies, forming a strong, seamless connection.

Maintenance and Inspection

Regular maintenance is essential to prolong the lifespan and efficiency of PPR fittings. Inspect fittings periodically for signs of wear, corrosion, or damage, especially in areas prone to high temperatures or chemical exposure. Replace any fittings showing signs of degradation promptly to prevent potential leaks or system failures. Additionally, ensure that fittings remain properly secured and supported to prevent stress on joints and pipes over time. Periodically check for proper alignment and support of pipes to maintain the integrity of the entire plumbing system.

Common Issues and Troubleshooting

Despite their durability, PPR fittings may encounter issues such as leaks or joint failures over time. Common causes include improper installation techniques, insufficient fusion temperatures, or external damage to fittings during handling or operation. When troubleshooting issues, first assess the condition of the fittings and surrounding pipes for visible signs of damage or misalignment. Re-evaluate installation procedures to identify any potential areas for improvement or adjustment. Utilize appropriate tools and techniques to repair or replace faulty fittings as necessary, ensuring that all repairs maintain the original structural integrity and performance of the plumbing system.

Conclusion

In conclusion, mastering the installation and maintenance of PPR fittings is essential for achieving reliable plumbing systems in various applications. By selecting the right fittings, following proper installation procedures, conducting regular maintenance, and addressing any issues promptly, users can maximize the efficiency and lifespan of their PPR plumbing systems. This comprehensive guide provides a foundational understanding of PPR fittings, empowering users to confidently install, maintain, and troubleshoot these versatile components in residential, commercial, and industrial settings.

This structured approach ensures clarity, accuracy, and completeness in conveying essential information about PPR fittings installation and maintenance.

Related products

-

PPR Fittings

PPR Pipe and Fittings

-

PPR Fittings

PPR Fittings

-

PPR Fittings

PPR Pipe Fittings