Description

Introduction to uPVC Fittings

Unplasticized polyvinyl chloride (uPVC) fittings are widely used in drainage systems due to their excellent durability, chemical resistance, and low maintenance requirements. Unlike traditional materials like metal or clay, uPVC offers a lightweight yet robust solution for managing wastewater and stormwater. This article explores the essential aspects of uPVC fittings in drainage systems, including their benefits, types, installation practices, maintenance, and environmental considerations.

Benefits of uPVC Fittings

One of the primary advantages of uPVC fittings is their resistance to corrosion and chemicals. Unlike metal fittings that can rust or degrade over time, uPVC is impervious to most acids and alkalis, making it ideal for transporting wastewater and other aggressive substances. Additionally, uPVC is lightweight, which simplifies handling and installation, reducing labor costs. The smooth internal surface of uPVC fittings minimizes friction and blockage, enhancing flow efficiency. Furthermore, uPVC fittings are available in various sizes and configurations, allowing for versatile applications in residential, commercial, and industrial drainage systems.

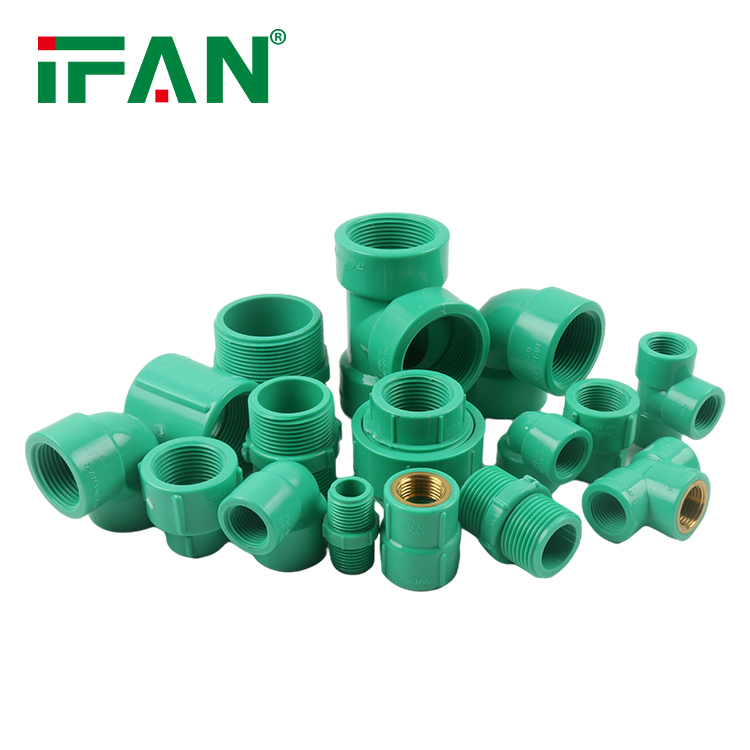

Types of uPVC Fittings

uPVC fittings come in various shapes and sizes, designed to accommodate different drainage needs. Common types include elbows, tees, reducers, and caps. Elbows are used to change the direction of pipe runs, while tees connect three pipes at a junction. Reducers enable the transition between different pipe diameters, and caps are used to seal the end of a pipe. Additionally, specialized fittings such as inspection chambers and manholes help facilitate maintenance and inspection of drainage systems. Selecting the appropriate type of fitting is crucial for ensuring a seamless and efficient drainage system.

Installation Practices

Proper installation of uPVC fittings is essential for the longevity and effectiveness of drainage systems. Before installation, it’s vital to ensure that the pipes and fittings are clean and free from debris. When joining fittings, using solvent cement is common practice, as it creates a strong, permanent bond. It’s important to follow manufacturer guidelines regarding curing times and ambient temperature during the installation process. Additionally, ensuring proper alignment and support for the piping system helps prevent strain on the fittings, reducing the likelihood of leaks or failures. Regular inspections during installation can help identify any potential issues early on.

Maintenance and Longevity

While uPVC fittings are known for their low maintenance requirements, periodic checks are still essential to ensure optimal performance. Regular inspections can help detect any signs of degradation, blockages, or leaks. If a blockage occurs, it’s often easy to clear with standard plumbing tools due to the smooth interior of uPVC pipes. Additionally, avoiding harsh chemical cleaners can help preserve the integrity of the fittings. By adopting a proactive maintenance schedule, property owners can extend the lifespan of their drainage systems and minimize costly repairs.

Environmental Considerations

In today’s environmentally conscious world, the sustainability of materials used in construction is paramount. uPVC fittings are recyclable, and many manufacturers have adopted eco-friendly practices in their production processes. This commitment to sustainability not only reduces waste but also ensures compliance with environmental regulations. Moreover, the energy efficiency associated with uPVC fittings—due to their lightweight nature and long lifespan—contributes to lower overall carbon footprints compared to traditional materials. Choosing uPVC fittings aligns with modern sustainable building practices, making them an excellent choice for environmentally responsible projects.

Conclusion

uPVC fittings play a crucial role in the efficiency and reliability of drainage systems. Their numerous benefits, including corrosion resistance, lightweight design, and versatility, make them a preferred choice for various applications. Understanding the types of fittings available, adhering to proper installation practices, and committing to regular maintenance will ensure the longevity and functionality of drainage systems. Furthermore, considering the environmental impact of materials used in drainage solutions highlights the importance of sustainable choices in modern construction. By selecting uPVC fittings, stakeholders can achieve effective drainage solutions that meet both performance and environmental standards.

Related products

-

CPVC ASTM2846

Elevating Piping Solutions: CPVC Fitting Elbow

-

PVC

UPVC Elbow