Description

An Overview of the Manufacturing Process of HDPE Fittings

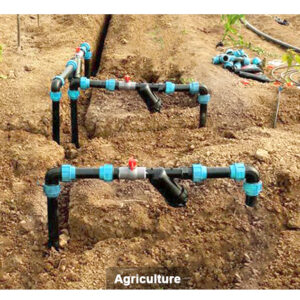

High-density polyethylene (HDPE) fittings have become a popular choice among manufacturers because of their durability and versatility. HDPE can be used for a wide range of applications, such as pipes, tanks, and fittings. The manufacturing process of HDPE fittings involves several steps that ensure the product’s quality and performance. This article provides an overview of the manufacturing process of HDPE fittings, highlights the product’s features and benefits, and emphasizes its value in industry applications.

The manufacturing process of HDPE fittings starts with the selection of the raw material. HDPE resins are chosen for their molecular weight, melt flow rate, and density. The chosen resin is then fed into an extruder, where it undergoes a melting process. The molten HDPE is then formed into a shape using a die, which is similar to a mold.

Once the shape has been formed, it undergoes a cooling process to solidify the material. The cooling process can either be through air or water. After cooling, the product is cut and finished to the desired specifications. This process involves machining, drilling, and sanding, among others.

HDPE fittings have several features that make them attractive to manufacturers. They have excellent resistance to chemicals, corrosion, and abrasion. They are also lightweight, easy to install, and require minimal maintenance. Additionally, they have a long lifespan, making them a cost-effective choice for many applications.

The benefits of using HDPE fittings in industrial applications are numerous. They can withstand extreme temperatures, providing a stable environment for products. They can also handle high pressures, ensuring the safety of the application. They are also resistant to impacts, providing a higher level of protection. Additionally, HDPE fittings are recyclable, making them eco-friendly and sustainable.

In conclusion, HDPE fittings have gained popularity in the manufacturing industry due to their durability, versatility, and cost-effectiveness. The manufacturing process involves several steps that ensure the product’s quality and performance. HDPE fittings have numerous features and benefits that make them an attractive choice for industrial applications. Companies can benefit from using HDPE fittings by enhancing their product’s safety, reliability, and sustainability. The use of HDPE fittings demonstrates a strong commitment to meeting industry standards and protecting the environment.

<a href=”https://www.ifanindus.com/contact-us/” rel=”noopener” target=”_blank”>Free Sample(Click Here to Get Free Sample)</a>