IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

In modern plumbing and water distribution systems, the choice of materials plays a crucial role in ensuring longevity, efficiency, and cost-effectiveness. Among the various options available, HDPE fittings have emerged as one of the best solutions for water distribution networks. These fittings, made from high-density polyethylene, offer several advantages over other materials like PPR fittings, especially in terms of durability, resistance to corrosion, and flexibility. This article delves into the reasons why HDPE fittings are the best choice for water distribution systems, with a special comparison to PPR fittings.

What Are HDPE Fittings?

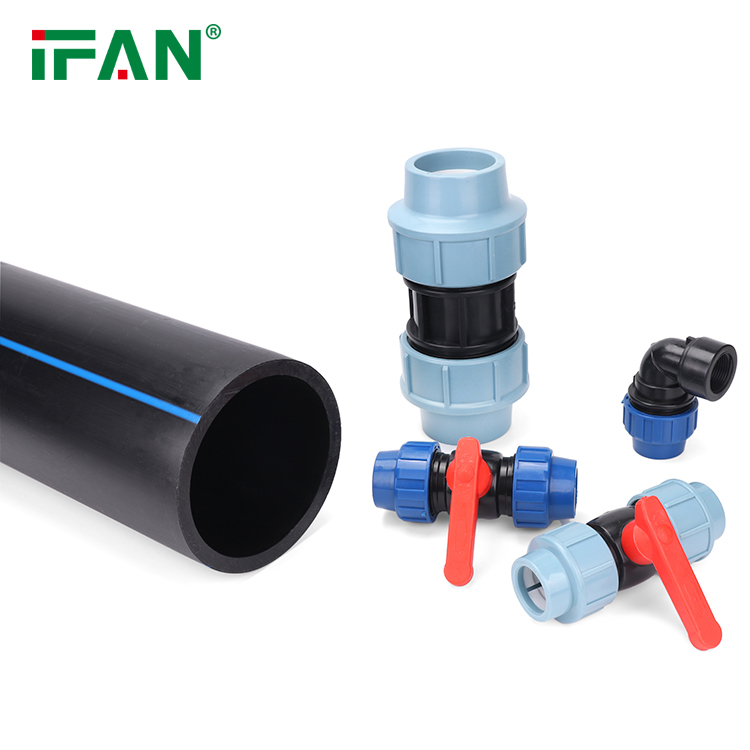

High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its strength and durability. HDPE fittings are designed to connect HDPE pipes, forming a system that can effectively carry water for long periods. HDPE fittings come in a variety of forms, including elbows, tees, couplings, reducers, and flanges, all of which are used to connect sections of HDPE pipes in water distribution networks.

HDPE fittings are increasingly used in municipal water supply, irrigation, and sewage systems due to their robustness and cost-efficiency. Although PPR fittings are also widely used in water systems, particularly for hot and cold water supply, HDPE fittings offer superior advantages when it comes to long-term performance.

Why Choose HDPE Fittings for Water Distribution?

1. Durability and Longevity

One of the most significant advantages of HDPE fittings is their exceptional durability. These fittings are resistant to wear and tear, making them ideal for systems that require longevity. HDPE has a high resistance to various physical stresses and external factors, ensuring that water distribution systems can last for decades without needing replacement.

The lifespan of HDPE fittings is typically over 50 years, making them a long-term investment. This longevity is especially critical in water distribution networks, where failure or damage to piping systems can lead to costly repairs and service interruptions.

2. Corrosion Resistance

Unlike traditional metal pipes, which are prone to rust and corrosion when exposed to water and chemicals, HDPE fittings are highly resistant to corrosion. In areas with high moisture levels or where the water has a high concentration of minerals and chemicals, HDPE fittings can withstand the harsh environment without deteriorating over time.

In contrast, PPR fittings, although resistant to many chemicals, do not offer the same level of protection against environmental corrosion, especially when exposed to acidic or saline water. This makes HDPE fittings more reliable in diverse environments.

3. Flexibility and Easy Installation

HDPE fittings are renowned for their flexibility, which is particularly useful when the piping system needs to navigate through obstacles. This flexibility makes installation easier, as the fittings can bend and stretch without breaking, reducing the need for additional joints and connectors.

In addition to flexibility, HDPE fittings can be fused together using a heat fusion process, creating a strong and leak-free connection. The fusion process eliminates the need for additional sealing materials, reducing the risk of leaks and ensuring a watertight system.

Although PPR fittings are also relatively easy to install, they do not offer the same level of flexibility. PPR fittings require threaded connections or welding, which may not be as convenient for complex installations.

4. Resistance to Chemicals

Another significant advantage of HDPE fittings is their ability to resist a wide range of chemicals. In water distribution systems, water often contains chemicals, minerals, and pollutants that can degrade the quality and integrity of the piping system. HDPE fittings provide an excellent barrier against such substances, preventing chemical reactions that could weaken the system.

While PPR fittings are resistant to many common household chemicals, they do not offer the same level of protection against industrial chemicals, which are often present in large-scale water distribution networks. This makes HDPE fittings the better choice for systems exposed to harsh industrial environments.

5. Cost-Effectiveness

Although HDPE fittings may have a slightly higher upfront cost than other materials, they provide significant savings over time due to their longevity, minimal maintenance requirements, and resistance to damage. Over the lifespan of a water distribution system, HDPE fittings help reduce operational costs by minimizing the need for repairs, replacements, and maintenance.

In comparison, PPR fittings, while affordable, do not have the same level of long-term savings, especially when exposed to environmental factors that could lead to damage or reduced performance. This makes HDPE fittings a more cost-effective option for large-scale water distribution systems.

6. Environmental Benefits

HDPE is a recyclable material, which makes it an environmentally friendly option for piping systems. Unlike PVC or metal pipes, which may release harmful substances when disposed of, HDPE fittings can be recycled and reused, reducing the overall environmental impact.

The durability of HDPE fittings also contributes to their environmental benefits. With fewer replacements and repairs needed, HDPE systems produce less waste over time, making them a more sustainable choice compared to materials that degrade more quickly.

7. Smooth Interior Surface

The smooth interior surface of HDPE fittings helps reduce the buildup of deposits or scaling inside the pipes, ensuring that water flow remains consistent and efficient. This smoothness also reduces the likelihood of blockages or clogs that can occur in pipes with rough or corroded surfaces.

PPR fittings, while smooth, do not offer the same level of long-term performance in terms of reducing buildup or maintaining optimal flow conditions, especially in systems with varying water qualities.

Applications of HDPE Fittings in Water Distribution

HDPE fittings are widely used in various water distribution applications, including:

- Municipal Water Supply: HDPE fittings are ideal for municipal water supply systems, where long-term durability and resistance to corrosion are critical.

- Irrigation: In agricultural applications, HDPE fittings are used for irrigation systems due to their flexibility and resistance to chemicals in fertilizers and pesticides.

- Sewerage Systems: HDPE is also used in sewage and drainage systems, where its resistance to corrosion and environmental factors is crucial.

- Industrial Water Systems: HDPE fittings are often used in industrial water systems where chemicals or other harsh substances may be present.

HDPE vs. PPR Fittings: Which One Should You Choose?

While PPR fittings are excellent for hot and cold water systems, HDPE fittings offer superior performance for larger water distribution systems. The main differences between the two include:

- Durability: HDPE fittings have a longer lifespan, often exceeding 50 years, while PPR fittings may require replacement sooner in some conditions.

- Flexibility: HDPE fittings are more flexible, which is beneficial for complex installations.

- Resistance to Corrosion: HDPE fittings are more resistant to corrosion and chemicals, making them better suited for harsh environments.

Conclusion

HDPE fittings are undoubtedly the best choice for water distribution systems, offering a combination of durability, resistance to corrosion, flexibility, and cost-effectiveness. While PPR fittings have their advantages, especially for domestic plumbing, HDPE fittings stand out when it comes to large-scale, long-term water distribution systems that require reliability and minimal maintenance.

Frequently Asked Questions (FAQs)

1. What are HDPE fittings made of?

HDPE fittings are made from high-density polyethylene, a durable, flexible thermoplastic polymer known for its strength and resistance to environmental factors.

2. Can HDPE fittings be used for hot water systems?

HDPE fittings can be used in hot water systems, but they are generally preferred for cold water and industrial applications due to their superior durability and resistance to chemicals.

3. How long do HDPE fittings last?

HDPE fittings typically last over 50 years, making them a long-lasting solution for water distribution systems.

4. Are HDPE fittings easy to install?

Yes, HDPE fittings are easy to install, particularly due to the heat fusion process, which creates leak-proof connections without the need for additional sealing materials.

5. How do HDPE fittings compare to PPR fittings?

While both HDPE and PPR fittings are reliable, HDPE fittings are better for larger, long-term water distribution systems due to their superior durability, resistance to corrosion, and flexibility. PPR fittings are ideal for residential hot and cold water systems.