IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

In the world of industrial plumbing, choosing the right materials for pipe systems is crucial for long-term efficiency and cost-effectiveness. HDPE fittings (High-Density Polyethylene fittings) have become a preferred choice for many industries due to their numerous benefits. In this article, we’ll explore the top 5 advantages of using HDPE fittings in industrial plumbing, highlighting why they are the best option for a variety of applications.

What are HDPE Fittings?

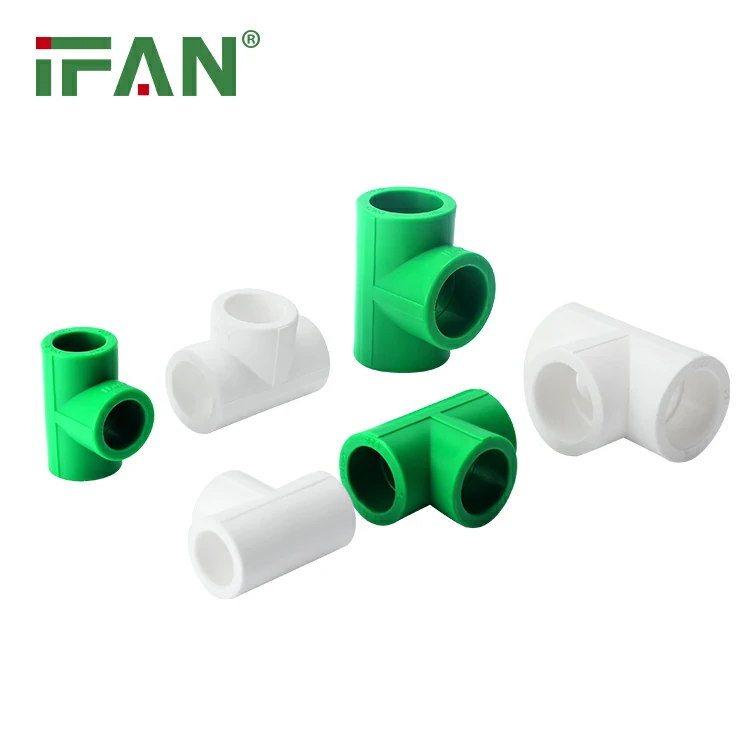

Before diving into the advantages, let’s define HDPE fittings. High-Density Polyethylene (HDPE) is a type of thermoplastic polymer made from petroleum. HDPE fittings are used in piping systems to connect, redirect, or branch out water, chemicals, or gases. They come in various shapes and sizes, including elbows, tees, couplings, and reducers. Due to their superior characteristics, HDPE fittings are highly favored in both industrial and municipal plumbing projects.

Top 5 Advantages of HDPE Fittings in Industrial Plumbing

1. Durability and Longevity

One of the biggest advantages of HDPE fittings is their incredible durability. Unlike traditional metal pipes that corrode or rust over time, HDPE fittings are resistant to corrosion, chemical reactions, and other environmental factors. HDPE fittings can withstand harsh conditions such as high pressure, temperature fluctuations, and exposure to chemicals without deteriorating.

This long-lasting performance means that HDPE fittings have a much longer lifespan compared to other materials, reducing the need for frequent replacements. The resistance to corrosion also helps to keep the plumbing system free from leaks and failures, ensuring operational continuity in industries where downtime is costly.

Why is this important?

Industrial plumbing systems often carry chemicals, wastewater, or other harsh substances. The ability of HDPE fittings to handle these elements without degradation significantly reduces maintenance costs and increases the overall lifespan of the system.

2. Resistance to Corrosion and Chemicals

Industrial plumbing systems often deal with a variety of corrosive substances, from chemicals to salts and acids. HDPE fittings offer excellent resistance to corrosion and are highly resistant to chemical attacks. This makes them an ideal choice for industries dealing with aggressive substances, such as chemical manufacturing, wastewater treatment, and oil and gas operations.

The non-corrosive nature of HDPE fittings prevents rust from forming, ensuring that the plumbing system remains strong and leak-free. This resistance to corrosion not only prolongs the lifespan of the fittings but also helps to maintain the quality and purity of the fluids being transported.

Why is this important?

In many industrial applications, maintaining the integrity of the fluid being transported is essential. HDPE fittings ensure that the fluids or gases remain uncontaminated by the piping material, which is especially critical in industries like pharmaceuticals, food processing, and petrochemicals.

3. Flexibility and Ease of Installation

HDPE fittings offer exceptional flexibility, making them easier to install compared to rigid pipe systems. The material can bend without breaking, allowing for curved or complex piping designs. This flexibility also means that HDPE fittings can adjust to ground shifts, reducing the risk of pipeline failure caused by external pressure or movement.

The installation process for HDPE fittings is also straightforward, requiring fewer tools and less time than other materials like metal or concrete pipes. With modern welding technologies such as butt fusion and electrofusion welding, the process becomes even more efficient and secure.

Why is this important?

In industrial plumbing, time is money. The ability to install HDPE fittings quickly and without specialized equipment reduces installation time, cutting down on labor costs. Additionally, the flexibility of the material makes it easier to adapt to complex layouts, minimizing the need for custom fittings and reducing installation errors.

4. Leak-Proof and Secure Joints

One of the most critical aspects of industrial plumbing is ensuring that there are no leaks. Leaks in a plumbing system can lead to hazardous conditions, environmental contamination, and costly downtime. HDPE fittings are designed to provide strong, leak-proof joints, even under high pressure.

Using welding methods like butt fusion or electrofusion welding, HDPE fittings form solid, continuous joints that eliminate the possibility of leaks. These joints are smooth, making it difficult for any liquid or gas to escape. Furthermore, the fused joints are as strong as the pipe itself, providing a long-lasting, reliable connection.

Why is this important?

Leak prevention is vital in industrial settings, particularly in hazardous industries such as oil and gas or chemical manufacturing. Even a small leak can result in significant safety risks or environmental damage. The leak-proof nature of HDPE fittings ensures a safe and secure plumbing system.

5. Cost-Effectiveness

While the initial cost of HDPE fittings may be slightly higher than traditional materials, the long-term benefits far outweigh the initial investment. HDPE fittings reduce the need for frequent replacements, require less maintenance, and have lower operational costs over time. This makes them a highly cost-effective solution for industrial plumbing systems.

Moreover, the ease of installation and flexibility of HDPE fittings means that you can save on labor costs and reduce the overall project timeline. The durability and resistance to damage also mean fewer repairs are needed over the years.

Why is this important?

Industries are always looking for ways to reduce costs while maintaining efficiency and safety. HDPE fittings offer an affordable solution that provides long-term savings by reducing maintenance, replacements, and operational downtime.

Conclusion

HDPE fittings offer numerous advantages for industrial plumbing systems. Their durability, chemical resistance, flexibility, leak-proof joints, and cost-effectiveness make them the ideal choice for industries requiring reliable and long-lasting plumbing solutions. By opting for HDPE fittings, businesses can ensure that their plumbing systems are efficient, secure, and low-maintenance, which is essential for maintaining productivity and reducing costs in the long run.

Frequently Asked Questions (FAQs)

1. What are HDPE fittings made of?

HDPE fittings are made of high-density polyethylene, a type of thermoplastic polymer known for its strength, durability, and resistance to corrosion and chemicals.

2. How do you install HDPE fittings?

HDPE fittings are typically installed using fusion welding methods like butt fusion or electrofusion welding. These methods create strong, leak-proof joints that are as durable as the pipe itself.

3. Can HDPE fittings be used in high-temperature applications?

Yes, HDPE fittings can withstand moderate temperature fluctuations. However, for extremely high-temperature applications, you may need to consult with a professional to ensure compatibility.

4. Are HDPE fittings more expensive than other materials?

While HDPE fittings may have a slightly higher initial cost than traditional materials, their durability, low maintenance requirements, and long lifespan make them a more cost-effective solution in the long run.

5. Can HDPE fittings be recycled?

Yes, HDPE fittings are recyclable, making them an environmentally friendly option for industrial plumbing. Recycled HDPE can be used to produce new products, reducing waste and environmental impact.