PPR (Polypropylene Random Copolymer) fiberglass pipes are an innovative solution for various plumbing and industrial applications. Combining the benefits of PPR pipes and fiberglass reinforcement, these pipes offer excellent durability, strength, and corrosion resistance. In this comprehensive overview, we will explore the key aspects of PPR fiberglass pipes. Let’s break down each aspect into separate sections.

1. Understanding PPR Fiberglass Pipes

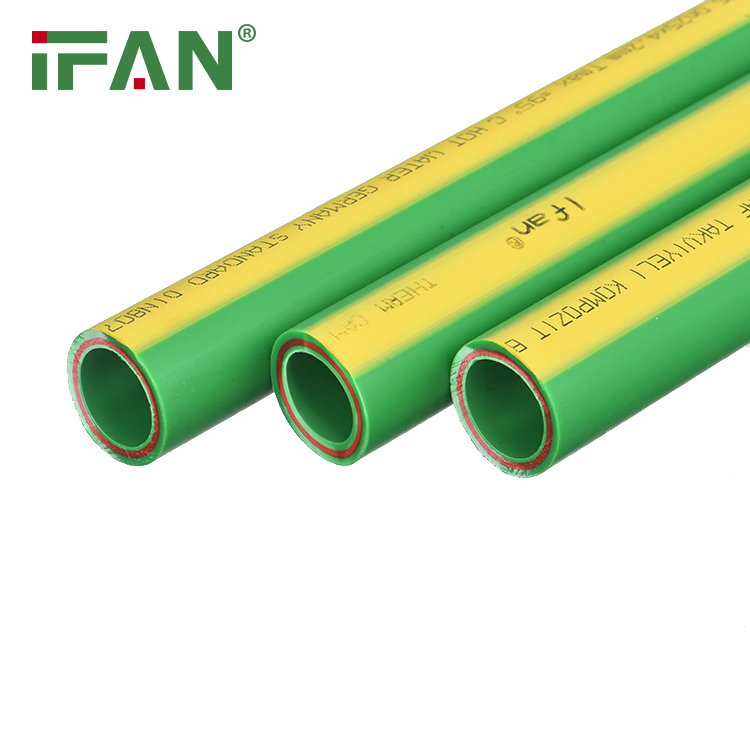

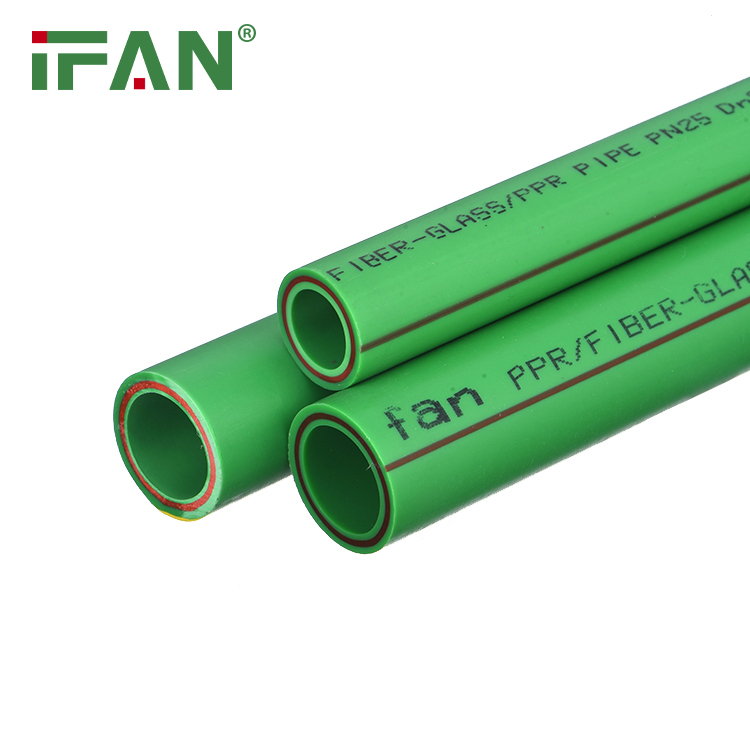

PPR fiberglass pipes are made by combining layers of PPR material with fiberglass reinforcement. The PPR material provides excellent chemical resistance and a smooth inner surface, ensuring optimal fluid flow. The fiberglass reinforcement adds strength and rigidity to the pipes, making them highly durable and resistant to external impacts.

2. Advantages of PPR Fiberglass Pipes

PPR fiberglass pipes offer several advantages over traditional piping systems. They have a longer lifespan, as the combination of PPR and fiberglass makes them highly resistant to corrosion, chemical degradation, and UV radiation. Additionally, the smooth inner surface of PPR fiberglass pipes minimizes pressure losses and prevents the buildup of deposits, ensuring efficient water flow.

3. Applications of PPR Fiberglass Pipes

PPR fiberglass pipes find applications in a wide range of industries, including plumbing, HVAC (Heating, Ventilation, and Air Conditioning), and industrial processes. They are commonly used for hot and cold water supply systems, compressed air systems, chemical transport, and underground installations. The versatility and durability of PPR fiberglass pipes make them suitable for both residential and commercial applications.

4. Installation of PPR Fiberglass Pipes

Installing PPR fiberglass pipes follows similar procedures to traditional pipe installations. These pipes are lightweight and easy to handle, making the installation process more convenient. PPR fiberglass pipes are typically joined using heat fusion techniques, ensuring strong and leak-free connections. The flexibility of PPR fiberglass pipes allows for easy maneuverability around obstacles and reduces the need for additional fittings.

5. Maintenance and Durability

PPR fiberglass pipes require minimal maintenance due to their exceptional durability. They are resistant to scaling, rusting, and corrosion, reducing the risk of costly repairs or replacements. Regular inspections should be conducted to ensure there are no signs of damage or leaks. Routine maintenance may involve simple cleaning and checking for any external factors that may affect the pipes’ performance.

6. Environmental Considerations

PPR fiberglass pipes are considered environmentally friendly due to their recyclability and long service life. The production process of PPR fiberglass pipes consumes less energy compared to other materials, contributing to lower carbon emissions. Additionally, the durability of these pipes reduces the need for frequent replacements, minimizing waste generation.

7. Standards and Certifications

PPR fiberglass pipes are manufactured in compliance with international standards and certifications, ensuring product quality and reliability. Common standards include ISO 15874 for plastic piping systems, ISO 9001 for quality management, and NSF/ANSI 14 and NSF/ANSI 61 for drinking water safety.

Conclusion

PPR fiberglass pipes offer a superior solution for plumbing and industrial applications, providing durability, strength, and corrosion resistance. With their numerous advantages, including long lifespan, efficient water flow, and easy installation, PPR fiberglass pipes are becoming increasingly popular across various industries. By understanding the features, applications, and maintenance considerations of PPR fiberglass pipes, users can make informed decisions and leverage the benefits offered by this advanced piping technology.