How HDPE Fittings Are Revolutionizing the Construction Industry

The use of High-Density Polyethylene (HDPE) fittings is rapidly gaining popularity in the construction industry due to its various benefits over conventional fittings. HDPE fittings are made of sturdy and long-lasting materials that are resistant to corrosion, abrasion, and ultraviolet rays, making them an ideal choice for applications that require high strength and durability.

HDPE fittings are widely used in various construction projects such as water supply pipelines, gas pipelines, and sewer systems. They are easy to install and require minimal maintenance, reducing the overall cost of construction. Due to their lightweight, they are easy to transport and handle, saving time and effort.

The main advantage of using HDPE fittings is that they are flexible, allowing for easy installation in tight corners and uneven terrain. They are also suitable for use in extreme temperatures and harsh conditions, making them a reliable choice for pipelines in remote locations.

HDPE fittings are also environmentally friendly since they are made of recyclable materials that are safe for the environment. They are also resistant to chemicals, preventing any harmful substances from leaching into the ground.

Another benefit of HDPE fittings is that they are fusion-welded, providing a leak-proof and seamless connection that can withstand high pressure and temperature changes. This reduces the risk of leaks, damages, and costly repairs, ensuring long-term reliability and security.

In conclusion, HDPE fittings are a revolutionary product in the construction industry. They provide numerous benefits such as durability, flexibility, environmental friendliness, and leak-proof connections. By adopting HDPE fittings, construction companies can reduce their overall cost, increase efficiency and reliability, and contribute to a safer and cleaner environment. If you are in the construction industry, it is high time to consider using HDPE fittings and take advantage of their immense benefits.

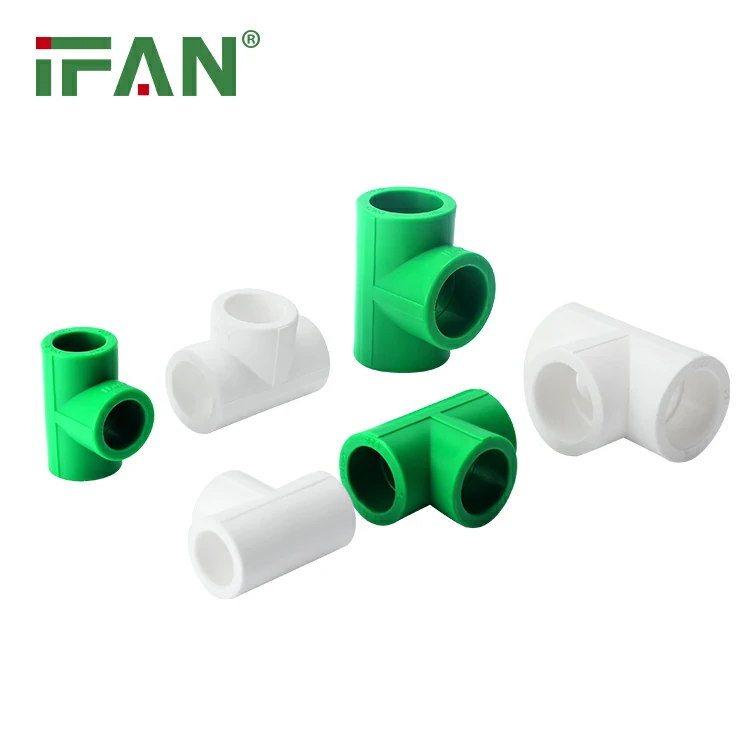

IFAN factory started in 1993. And IFAN has workshop 120000 square meter with 610 staff. IFAN can design and produce all plumbing pipe and fitting include PPR,PVC,CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting ,brass fitting, brass ball valve ,heating system , gas system , sanitary faucets and hose, In the past 30 Years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory use best materials to produce high quality pipe and fittings with automatic production line and high tech quality control machines. The most important,IFAN can guarantee that all pipes and fittings manufactured by IFAN are qualified.

Free Sample(Click Here to Get Free Sample)