Introduction

If you own a home built in the 1940s, you might be dealing with various plumbing materials, including galvanized steel pipes and, more recently, PEX (cross-linked polyethylene) pipes. As plumbing technology has evolved, homeowners face the question of whether to replace older piping systems, particularly when it comes to galvanized pipes. This article will explore the considerations surrounding galvanized pipes, the advantages of PEX and PPR (Polypropylene Random Copolymer) pipes, and whether you need to replace all the galvanized pipes in your home.

Understanding Galvanized Pipes

What are Galvanized Pipes?

Galvanized pipes are steel pipes that have been coated with a layer of zinc to protect them from corrosion and rust. This coating was a common practice in plumbing systems from the late 19th century until the 1960s. While galvanized pipes were once the standard for water supply lines, they have several drawbacks that can affect the quality of your plumbing system.

Problems with Galvanized Pipes

- Corrosion: Over time, the zinc coating can wear away, leading to rust and corrosion within the pipe. This can result in leaks and reduced water flow.

- Reduced Water Quality: Rust and corrosion can contaminate the water supply, leading to discolored or foul-smelling water.

- Low Water Pressure: Corrosion can cause buildup inside the pipes, leading to reduced water pressure and flow.

- Longevity Issues: Galvanized pipes typically have a lifespan of 20 to 50 years, depending on water quality and environmental conditions. Many homes with galvanized plumbing may be nearing the end of their pipes’ useful life.

Understanding PEX Pipes

What are PEX Pipes?

PEX pipes are made from cross-linked polyethylene, a flexible plastic material that has become increasingly popular for residential plumbing systems. PEX pipes offer several advantages over traditional materials, including galvanized steel.

Benefits of PEX Pipes

- Flexibility: PEX pipes can bend and curve easily, allowing for quick and efficient installation, especially in tight spaces.

- Corrosion Resistance: Unlike galvanized pipes, PEX is resistant to corrosion and scale buildup, ensuring a longer lifespan and better water quality.

- Thermal Insulation: PEX pipes provide excellent insulation, helping to maintain water temperature and reduce energy costs.

- Cost-Effective: While the initial cost of PEX may be higher than galvanized pipes, the long-term savings from reduced maintenance and energy costs make it a cost-effective choice.

- Noise Reduction: PEX pipes are quieter than metal pipes, minimizing noise from water flow, which is particularly advantageous in residential settings.

Understanding PPR Pipes

What are PPR Pipes?

Polypropylene Random Copolymer (PPR) pipes are made from a thermoplastic polymer known for its strength, durability, and resistance to chemical corrosion. PPR pipes are increasingly used in plumbing systems for hot and cold water supply.

Benefits of PPR Pipes

- Chemical Resistance: PPR pipes are highly resistant to a wide range of chemicals, making them suitable for various applications.

- Thermal Stability: PPR pipes can handle high temperatures, making them ideal for hot water applications.

- Longevity: PPR pipes have a lifespan that often exceeds 50 years, which reduces the need for frequent replacements.

- Eco-Friendly: Made from recyclable materials, PPR pipes contribute to sustainable plumbing solutions.

- Cost-Effective: While PPR pipes may have a higher initial cost, their longevity and low maintenance requirements make them a cost-effective choice over time.

Should You Replace All Galvanized Pipes?

Assessing the Condition of Your Galvanized Pipes

Before deciding to replace all the galvanized pipes in your home, it’s essential to assess their condition. Here are some steps to consider:

- Inspect for Leaks: Check for any visible leaks or signs of water damage around your plumbing fixtures. If leaks are present, it may be time to replace the affected sections.

- Check Water Quality: If you notice discolored or foul-smelling water, it may indicate corrosion inside the pipes. Conduct a water quality test to determine if contaminants are present.

- Evaluate Water Pressure: Low water pressure can indicate buildup within the pipes. If you experience significant pressure drops, it may be a sign that the pipes need replacement.

- Consult a Professional: A licensed plumber can conduct a thorough inspection of your plumbing system and provide recommendations based on the condition of your galvanized pipes.

Reasons to Replace Galvanized Pipes

- Health Concerns: If your galvanized pipes are corroded, they may be leaching rust and other contaminants into your drinking water, posing health risks.

- Increased Maintenance Costs: As galvanized pipes age, they are more prone to leaks and repairs, leading to increased maintenance costs over time.

- Long-Term Savings: Replacing galvanized pipes with PEX or PPR can lead to long-term savings due to reduced maintenance and improved water quality.

- Increased Property Value: Modernizing your plumbing system by replacing outdated galvanized pipes can enhance your home’s value and appeal to potential buyers.

Partial Replacement vs. Full Replacement

If only a few sections of your galvanized plumbing are in poor condition, you may consider a partial replacement. However, if your home has extensive galvanized piping, a full replacement may be more beneficial in the long run.

- Partial Replacement: This option may be more cost-effective initially, but it may not address underlying issues in the remaining galvanized pipes. If the rest of the system is nearing the end of its lifespan, you may find yourself facing similar problems shortly after.

- Full Replacement: Replacing all galvanized pipes with PEX or PPR can provide peace of mind, improved water quality, and long-term savings. While the upfront cost may be higher, the benefits often outweigh the initial investment.

The Process of Replacing Galvanized Pipes

1. Planning and Assessment

Before beginning the replacement process, conduct a thorough assessment of your plumbing system. Identify all sections of galvanized piping and determine the best replacement strategy.

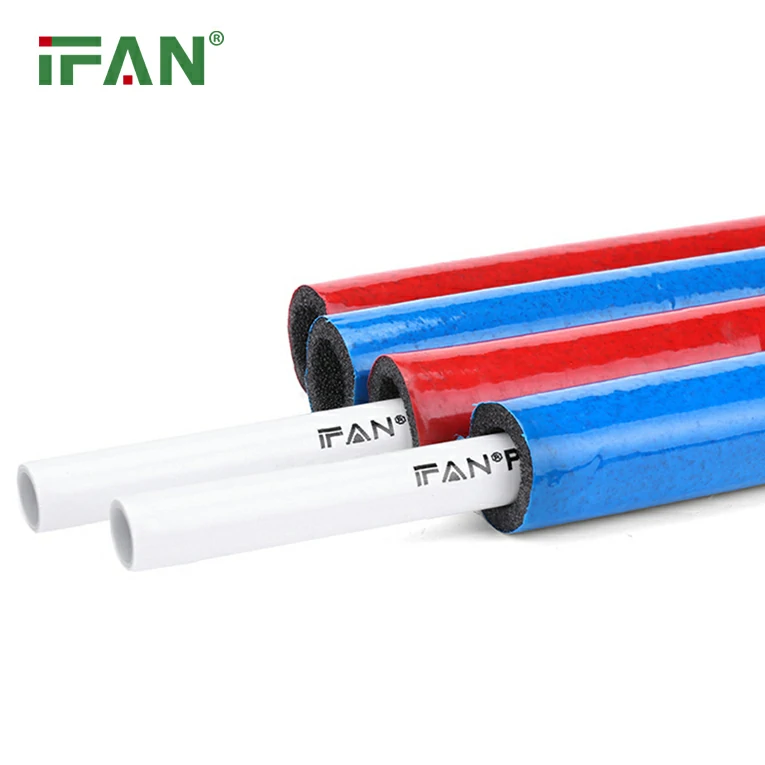

2. Choosing the Right Material

Decide whether to replace galvanized pipes with PEX or PPR. Both options offer unique advantages, so consider factors such as budget, application, and personal preferences.

3. Hiring a Professional Plumber

Engaging a licensed plumber with experience in pipe replacement is crucial for a successful project. They can ensure that the installation meets local building codes and regulations.

4. Installation Process

The installation process will typically involve the following steps:

- Shutting Off Water Supply: Before any work begins, the water supply must be turned off to prevent leaks and flooding.

- Removing Old Pipes: The plumber will carefully remove the existing galvanized pipes, taking care to minimize damage to surrounding structures.

- Installing New Pipes: The new PEX or PPR pipes will be installed according to the plumbing plan, ensuring proper connections and fittings.

- Testing the System: After installation, the plumber will test the system for leaks and ensure that water flows correctly.

5. Final Inspection

Once the installation is complete, a final inspection should be conducted to ensure that the new plumbing system is functioning correctly and meets all safety standards.

Conclusion

If you own a 1940s home with galvanized pipes, it is essential to assess their condition and consider the benefits of replacing them with modern materials like PEX or PPR. While it may not be necessary to replace all the galvanized pipes immediately, addressing any issues and planning for future replacements can lead to improved water quality, reduced maintenance costs, and enhanced property value. Engaging a professional plumber can help ensure a successful transition to a more reliable plumbing system.

Frequently Asked Questions (FAQs)

1. How can I tell if my galvanized pipes need to be replaced?

Signs of deterioration include leaks, discolored water, reduced water pressure, and rust buildup. A professional inspection can also help assess the condition of your pipes.

2. What are the benefits of replacing galvanized pipes with PEX?

Replacing galvanized pipes with PEX offers flexibility, corrosion resistance, improved water quality, and long-term cost savings due to reduced maintenance.

3. Are PPR pipes a good alternative to PEX?

Yes, PPR pipes are a durable and cost-effective alternative to PEX, offering excellent chemical resistance and longevity.

4. How long does the replacement process take?

The duration of the replacement process can vary depending on the size of the plumbing system and the extent of the work required. A typical replacement may take a few days.

5. Will replacing galvanized pipes increase my home’s value?

Modernizing your plumbing system by replacing outdated galvanized pipes can enhance your home’s value and appeal to potential buyers, making it a worthwhile investment.