IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

When choosing materials for plumbing systems, the decision between different types of pipe fittings can be overwhelming. PPR fittings (Polypropylene Random Copolymer fittings) have become a popular choice for modern plumbing systems due to their remarkable durability, cost-effectiveness, and ease of installation. However, PPR fittings are not the only option available, and it’s essential to understand how they compare to other pipe fittings like PVC, CPVC, PEX, and copper. This comparative analysis will break down the key differences between PPR fittings and these common alternatives, helping you make an informed decision for your plumbing needs.

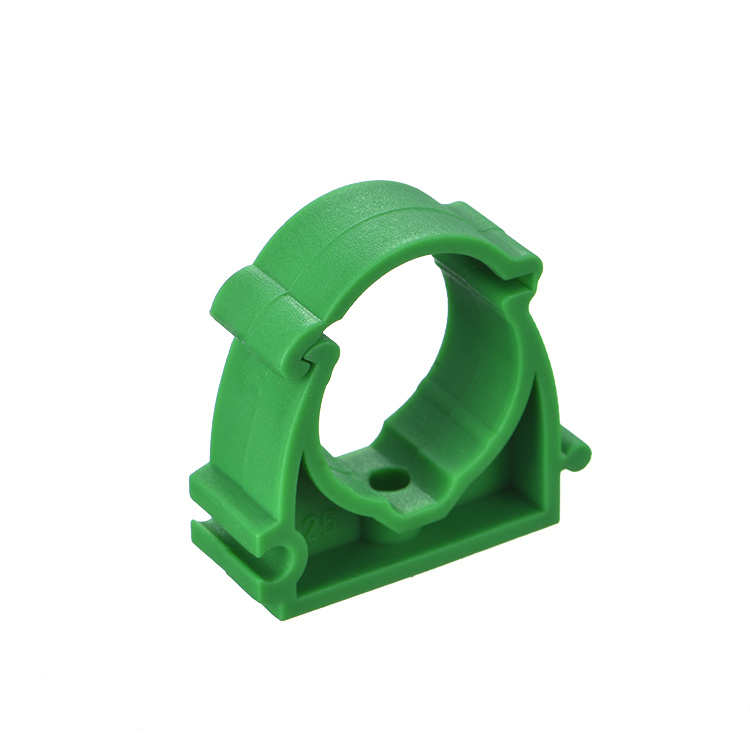

What Are PPR Fittings?

PPR fittings are made from polypropylene random copolymer, a durable thermoplastic polymer. These fittings are commonly used to connect pipes in water supply and heating systems. The connection is made through a fusion welding process, where the pipe and fitting are heated and then joined to create a seamless, leak-proof bond.

Key Comparisons: PPR Fittings vs. Other Pipe Fittings

1. Durability and Longevity

PPR fittings are known for their impressive durability and long lifespan. Unlike metal fittings, PPR fittings are not prone to rust or corrosion. They can last up to 50 years, making them an excellent choice for both cold and hot water systems.

In comparison, PVC fittings are less durable in high-temperature environments. PVC can degrade under heat and is more prone to cracking with age or under pressure. PEX (cross-linked polyethylene) fittings, while flexible, are generally more vulnerable to UV damage and physical wear, which can reduce their lifespan. Copper fittings, while robust, are susceptible to corrosion over time, especially in areas with hard water.

2. Resistance to Temperature and Pressure

One of the standout features of PPR fittings is their ability to handle high temperatures. These fittings can withstand water temperatures up to 95°C (203°F), making them ideal for both hot water supply and underfloor heating systems. They also perform well under pressure, maintaining their integrity even when exposed to fluctuating water pressure.

In contrast, PVC fittings are designed primarily for cold water systems, with a maximum operating temperature of around 60°C (140°F). CPVC fittings, which are a variant of PVC, can handle slightly higher temperatures, up to 93°C (200°F), making them suitable for hot water systems. PEX fittings, although more flexible and easier to install, typically can handle temperatures between 60°C to 80°C (140°F to 176°F). Copper fittings can withstand high temperatures but are more vulnerable to corrosion over time, especially in acidic or hard water.

3. Ease of Installation

PPR fittings are incredibly easy to install, especially when compared to copper fittings. The fusion welding process used for PPR fittings does not require any complicated tools or adhesives—just a fusion welding machine. This method ensures a strong, leak-proof connection every time.

In comparison, copper fittings require soldering or brazing, a process that can be time-consuming and requires specific tools and skills. PVC and CPVC fittings are easier to install than copper, as they use a solvent cementing method, but they still require a careful application of glue to ensure a secure connection. PEX fittings use a crimping tool or push-fit system, which is also relatively simple but requires specific tools and may not be as foolproof as fusion welding.

4. Cost-Effectiveness

When considering material and installation costs, PPR fittings are a very cost-effective option. The material itself is affordable, and since the installation process is straightforward and doesn’t require specialized labor or equipment, labor costs are also kept low. Over the long term, PPR fittings are an economical solution due to their durability and low maintenance needs.

PVC fittings are generally cheaper than PPR fittings, but they are not suitable for high-temperature or high-pressure systems. PEX fittings are more expensive than PPR and PVC, especially when considering the necessary installation tools. Copper fittings are the most expensive option, both in terms of material cost and installation, as soldering can be a labor-intensive process.

5. Corrosion and Chemical Resistance

PPR fittings are highly resistant to corrosion, scaling, and rust, making them ideal for both water supply and heating systems. These fittings maintain their integrity even in areas with hard water, where other materials may degrade over time.

In contrast, PVC and CPVC fittings are resistant to corrosion and scaling but can degrade when exposed to certain chemicals. PEX fittings are also resistant to corrosion and scaling but can be damaged by prolonged exposure to UV rays, which makes them unsuitable for outdoor applications unless properly shielded.

Copper fittings, while resistant to corrosion in many situations, are susceptible to corrosion over time, particularly when exposed to water with high acidity or minerals. Copper pipes also tend to react with certain substances, leading to discoloration of the water.

6. Environmental Impact

As sustainability becomes a growing concern in home construction, the environmental impact of the materials used is an important consideration. PPR fittings are made from recyclable materials, which makes them an eco-friendly option for plumbing systems. Additionally, their long lifespan reduces the need for frequent replacements, resulting in less waste.

PVC fittings are also made from recyclable materials, but the production of PVC involves the use of harmful chemicals, which can be an environmental concern. PEX fittings, while durable, are made from cross-linked polyethylene, which is not as easily recyclable as other materials. Copper fittings are recyclable but are also mined, which has a significant environmental footprint.

7. Water Flow Efficiency

The smooth inner surface of PPR fittings reduces friction, allowing water to flow more efficiently through the system. This feature makes PPR fittings an excellent choice for maintaining optimal water pressure in your plumbing system.

PVC and CPVC fittings also provide smooth surfaces, but they are not as effective as PPR fittings in maintaining water pressure over time. PEX fittings, being flexible, can sometimes cause water flow restrictions due to their inner surface texture. Copper fittings tend to have rougher surfaces due to corrosion, which can reduce the efficiency of water flow over time.

PPR Fittings vs. Other Pipe Fittings: A Final Verdict

In conclusion, PPR fittings offer several advantages over other common plumbing materials. They are durable, cost-effective, and resistant to temperature, pressure, and corrosion. Their ease of installation and long-term reliability make them an ideal choice for both residential and commercial plumbing systems.

While alternatives like PVC, CPVC, PEX, and copper fittings have their own merits, PPR fittings are an excellent all-around option, particularly for modern plumbing systems that demand both high performance and cost-efficiency.

FAQs About PPR Fittings

- What is the lifespan of PPR fittings?

- PPR fittings can last for over 50 years when properly installed, making them a long-term investment for your plumbing system.

- Can PPR fittings be used for outdoor plumbing?

- Yes, PPR fittings are resistant to UV rays and can be used for outdoor plumbing, though additional insulation is recommended in regions with extreme temperatures.

- Are PPR fittings suitable for gas lines?

- No, PPR fittings are not designed for use with gas lines. They are intended for water and heating systems only.

- How do I install PPR fittings?

- PPR fittings are installed using a fusion welding process, which requires a welding machine to heat and join the pipe and fitting together.

- Are PPR fittings eco-friendly?

- Yes, PPR fittings are made from recyclable materials, making them an eco-friendly option for plumbing systems.