IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

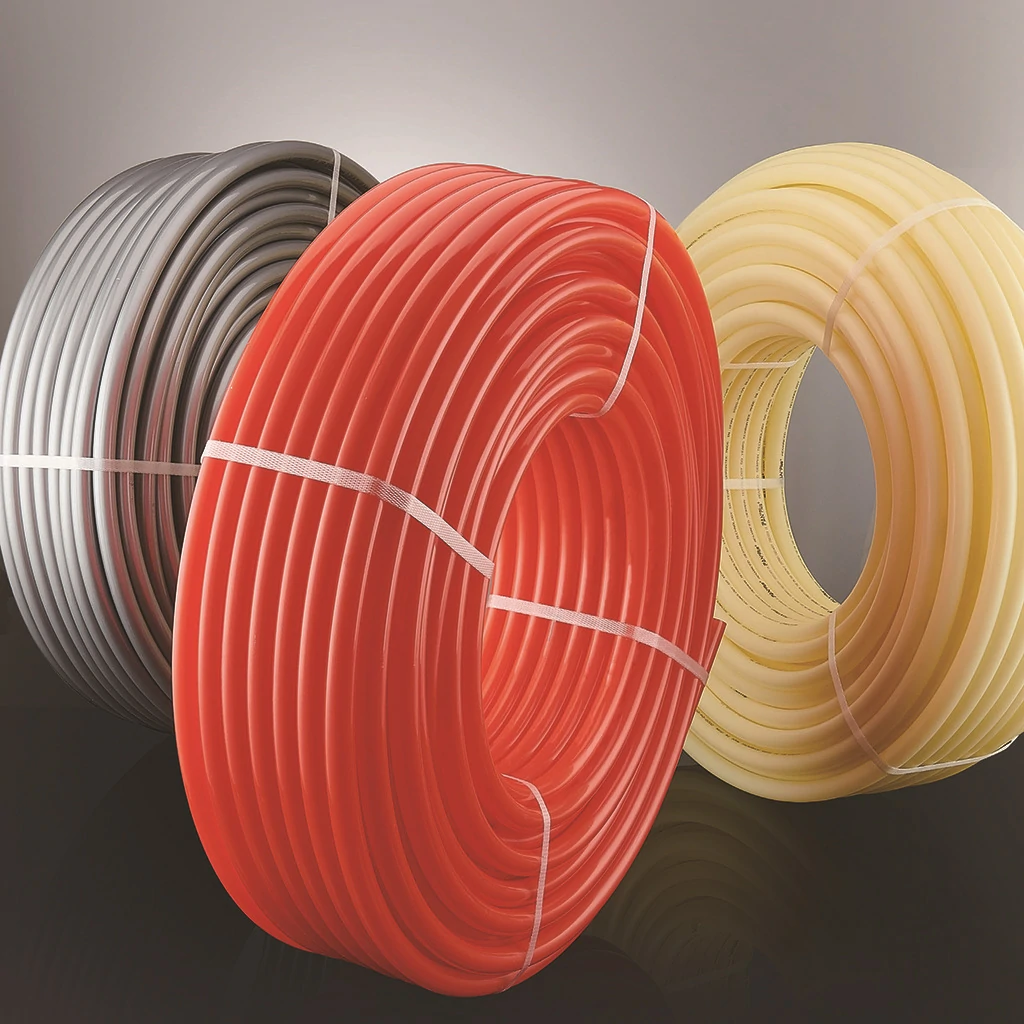

PEX (cross-linked polyethylene) underfloor heating systems have gained popularity for their efficiency and ease of installation compared to other geothermal heating systems. Here’s a comprehensive comparison analysis highlighting the key differences and benefits of PEX underfloor heating pipes:

1. Installation and System Layout

PEX underfloor heating systems are known for their straightforward installation process. Typically, PEX pipes are laid in a network beneath the floor surface, utilizing either a staple-up or screed installation method. This layout allows for even heat distribution across the floor area, creating a comfortable indoor environment. In contrast, other geothermal systems like hydronic radiators or forced-air systems may require more complex installation procedures involving ductwork or extensive piping, which can increase both labor and material costs.

2. Energy Efficiency and Operating Costs

One of the significant advantages of PEX underfloor heating systems lies in their energy efficiency. By distributing heat evenly across the floor, these systems operate at lower temperatures than traditional radiators, reducing energy consumption. Moreover, PEX pipes have excellent thermal conductivity, allowing for quick response times and efficient heat transfer. In comparison, forced-air systems can experience heat loss through ductwork, while hydronic radiators may require higher operating temperatures to achieve the same level of comfort, potentially increasing energy costs over time.

3. Comfort and Indoor Air Quality

PEX underfloor heating systems contribute to enhanced comfort and indoor air quality. Because they operate without blowing air or circulating dust particles, they create a quieter and cleaner environment compared to forced-air systems. The radiant heat from PEX pipes also eliminates cold spots and drafts, providing consistent warmth throughout the room. In contrast, forced-air systems can distribute allergens and dust, while hydronic radiators may create temperature variations within the room depending on their location.

4. Maintenance and Longevity

Maintenance requirements for PEX underfloor heating systems are minimal once installed correctly. PEX pipes are resistant to corrosion and scale buildup, reducing the risk of system failures over time. Periodic inspections and checks ensure continued performance. In comparison, hydronic radiators may require occasional bleeding to remove air bubbles, while forced-air systems necessitate filter changes and duct cleaning to maintain efficiency and indoor air quality.

5. Flexibility and Adaptability

PEX underfloor heating systems offer flexibility in design and adaptation to various building layouts and floor finishes. They can be easily integrated into new construction projects or retrofitted into existing buildings with minimal disruption. Additionally, PEX pipes can accommodate different types of flooring materials, including tile, wood, laminate, and carpet, without compromising performance. Other geothermal systems may have limitations regarding placement and installation, depending on the building’s structure and design requirements.

Conclusion

In conclusion, PEX underfloor heating systems stand out for their efficiency, comfort, and ease of installation compared to other geothermal heating systems like hydronic radiators and forced-air systems. By providing even heat distribution, lower energy consumption, and improved indoor air quality, PEX underfloor heating systems offer a compelling solution for residential and commercial applications alike. Understanding these differences allows homeowners and contractors to make informed decisions based on their specific heating needs, budget considerations, and long-term sustainability goals.