The brass fittings market has experienced significant growth over the past few years, driven by increasing demand across various sectors, including plumbing, HVAC, and automotive industries. As we look toward 2030, understanding the market size, share, and trends is crucial for stakeholders aiming to capitalize on this expanding industry. This article delves into the current landscape of the brass fittings market, key drivers of growth, challenges, and future projections.

1. Overview of the Brass Fittings Market

1.1. Definition of Brass Fittings

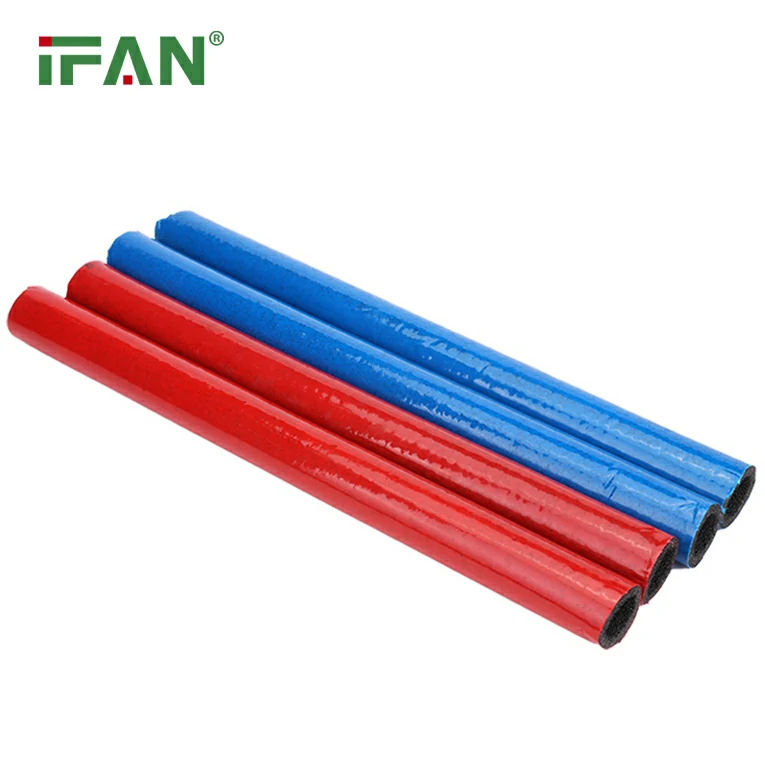

Brass fittings are components used in plumbing and piping systems to connect various sections of pipes, valves, and other devices. Made primarily from an alloy of copper and zinc, brass fittings are favored for their durability, corrosion resistance, and aesthetic appeal. They come in various forms, including elbows, tees, couplings, and adapters.

1.2. Market Dynamics

The brass fittings market is influenced by several factors, including:

- Growing Construction Industry: The rise in construction activities globally, particularly in emerging economies, is driving demand for brass fittings.

- Increased Infrastructure Development: Investments in infrastructure, such as water supply systems and transportation networks, are boosting the need for reliable plumbing solutions.

- Technological Advancements: Innovations in manufacturing processes are leading to the production of high-quality brass fittings, enhancing their performance and application range.

2. Market Size and Share Analysis

2.1. Current Market Size

As of 2023, the global brass fittings market is estimated to be valued at approximately USD 10 billion. This figure is projected to grow at a compound annual growth rate (CAGR) of around 5% from 2023 to 2030, reaching an estimated USD 14 billion by the end of the forecast period.

2.2. Regional Market Share

The brass fittings market is geographically segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- Asia-Pacific: This region holds the largest market share, driven by rapid urbanization, industrialization, and infrastructure development in countries like China and India.

- North America: The North American market is characterized by a mature construction sector and stringent regulations regarding plumbing materials, contributing to steady demand.

- Europe: The European market is witnessing growth due to increasing investments in renewable energy and sustainable building practices.

3. Key Drivers of Growth

3.1. Urbanization and Population Growth

The ongoing urbanization trend, particularly in developing countries, is a significant driver of demand for brass fittings. As more people move to urban areas, the need for residential and commercial buildings increases, subsequently boosting the demand for plumbing fittings.

3.2. Water Conservation Initiatives

Governments and organizations worldwide are implementing water conservation initiatives, leading to the adoption of efficient plumbing systems. Brass fittings, known for their durability and reliability, are often preferred for these applications, further driving market growth.

3.3. Industrial Applications

The industrial sector, particularly the oil and gas, HVAC, and automotive industries, is a substantial consumer of brass fittings. The growing need for efficient fluid management systems in these sectors is propelling the demand for high-quality brass fittings.

4. Challenges Facing the Brass Fittings Market

4.1. Fluctuating Raw Material Prices

The prices of copper and zinc, the primary materials used in brass fittings, can be volatile. Fluctuations in these prices can impact production costs and profit margins for manufacturers, posing a challenge to market growth.

4.2. Environmental Regulations

Increasing environmental regulations regarding the use of certain materials in plumbing systems may limit the use of brass fittings in some applications. Manufacturers must adapt to these regulations and explore alternative materials without compromising quality.

4.3. Competition from Alternative Materials

The brass fittings market faces competition from alternative materials such as plastic and stainless steel fittings, which may offer lower costs or specific advantages in certain applications. This competition can hinder market expansion, particularly in price-sensitive segments.

5. Future Trends and Projections

5.1. Sustainable Manufacturing Practices

As awareness of environmental issues grows, manufacturers are increasingly adopting sustainable practices. This includes using recycled materials in the production of brass fittings and implementing energy-efficient manufacturing processes.

5.2. Smart Plumbing Solutions

The integration of technology into plumbing systems is on the rise. Smart plumbing solutions that incorporate sensors and automation are becoming popular, leading to increased demand for compatible brass fittings that can support these advanced systems.

5.3. Expansion into Emerging Markets

Manufacturers are likely to focus on expanding their presence in emerging markets, where urbanization and infrastructure development are rapidly increasing. This strategic move can open new avenues for growth and revenue.

6. Conclusion

The brass fittings market is poised for significant growth over the next decade, driven by urbanization, industrial