IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

PPR fittings have become increasingly popular in modern plumbing systems due to their remarkable durability, longevity, and cost-effectiveness. Polypropylene Random Copolymer (PPR) fittings are known for their resistance to corrosion, ability to handle high temperatures, and ease of installation. These attributes make them an ideal choice for both residential and commercial plumbing projects. In this article, we’ll explore the durability and longevity of PPR fittings, what factors influence their lifespan, and how you can ensure your system lasts for decades.

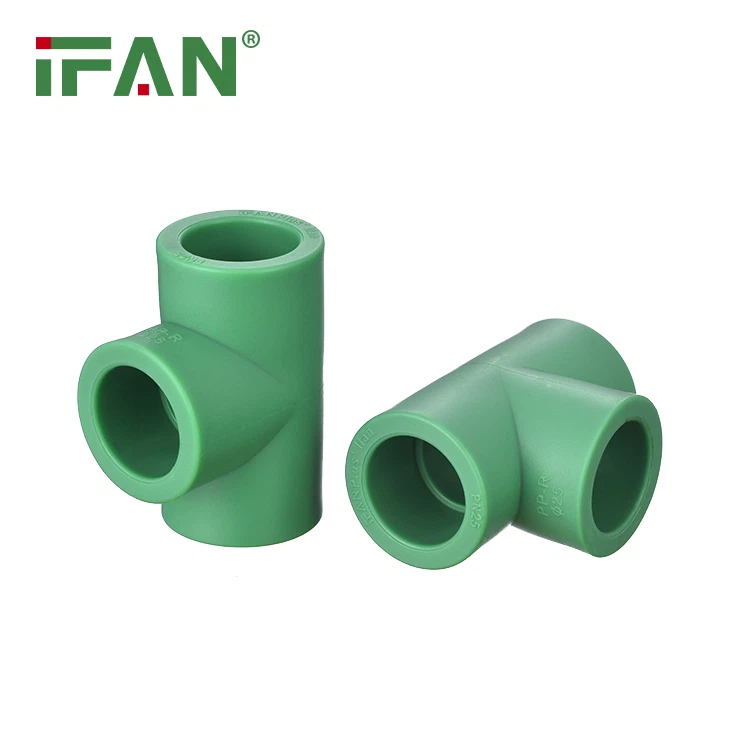

What Are PPR Fittings?

PPR fittings are plumbing components made from a type of plastic known as Polypropylene Random Copolymer. This material is specifically designed to withstand the demands of water distribution systems, including both hot and cold water installations. Unlike traditional materials like copper or galvanized steel, PPR fittings offer a number of advantages, including greater resistance to corrosion, lower weight, and a longer lifespan.

Why Choose PPR Fittings?

- Corrosion Resistance: PPR fittings are resistant to rust and corrosion, which significantly reduces maintenance and repair costs.

- High Temperature Tolerance: PPR fittings can handle water temperatures up to 95°C (203°F), making them suitable for both hot and cold water systems.

- Cost-Effectiveness: The cost of PPR fittings is generally lower than other materials, such as copper, making them an affordable option for homeowners and businesses alike.

- Ease of Installation: PPR fittings are easier and faster to install compared to other traditional materials, reducing labor costs and installation time.

Durability of PPR Fittings

One of the standout features of PPR fittings is their impressive durability. When installed properly, PPR fittings can last for several decades without requiring significant maintenance or replacement. This is in stark contrast to other plumbing materials like copper or steel, which are prone to corrosion and degradation over time.

Factors That Influence PPR Fitting Durability

While PPR fittings are known for their robustness, their longevity can still be influenced by several factors. These include:

1. Quality of Materials

The overall quality of PPR fittings plays a major role in determining their durability. High-quality PPR fittings are manufactured from superior-grade polypropylene copolymer materials. These fittings will be more resistant to external damage and harsh environmental conditions, ensuring a longer service life. Always opt for reputable manufacturers and suppliers to guarantee you’re using reliable and durable fittings.

2. Installation Process

Proper installation is crucial to the longevity of PPR fittings. If the pipes and fittings are not installed correctly, it can lead to weak joints, leaks, and potential failures. The installation process involves welding the fittings to the pipes, typically using a fusion machine that ensures a strong, secure connection. When done right, the joint will be seamless and robust, preventing issues like leaks or system breakdowns.

3. Water Quality

The quality of water circulating through your PPR pipes also affects the fittings’ durability. Water with high levels of chlorine, calcium, or other aggressive chemicals can erode and damage plumbing materials, including PPR. However, PPR fittings are highly resistant to most chemicals, which means they can handle a variety of water qualities. Regular water testing and treatment can help prolong the life of your plumbing system.

4. Temperature and Pressure Conditions

PPR fittings are designed to withstand high water temperatures up to 95°C (203°F). However, exposing the system to extreme temperature fluctuations or consistent high pressures can shorten its lifespan. It’s essential to install PPR fittings in systems where temperature and pressure levels remain within the recommended range. This helps avoid premature wear and failure.

5. Environmental Factors

Environmental conditions, such as exposure to UV rays or extreme outdoor temperatures, can impact the durability of PPR fittings. While PPR fittings are designed to be UV-resistant, prolonged exposure to direct sunlight can still degrade the material over time. For outdoor installations, it’s recommended to cover or shield the pipes from direct sunlight to prevent any potential damage. Insulating the pipes in colder climates can also help protect them from freezing.

Longevity of PPR Fittings

PPR fittings are known for their extended service life. Under ideal conditions, they can last up to 50 years or more, depending on usage and installation factors. Several key factors contribute to this impressive lifespan:

1. Corrosion Resistance

Unlike metal pipes and fittings, PPR fittings do not corrode over time. This is one of the primary reasons for their long-lasting durability. The absence of corrosion significantly reduces the chances of leaks or structural failures, resulting in a maintenance-free experience for homeowners and businesses.

2. Low Maintenance Needs

PPR fittings require minimal maintenance over their lifetime. Regular inspections to check for leaks or damage are generally sufficient. However, due to the corrosion resistance of PPR fittings, these inspections often reveal no significant wear. This is a stark contrast to metal fittings, which require regular maintenance to avoid rust and deterioration.

3. Impact Resistance

PPR fittings are highly resistant to physical impacts, such as accidental bumps or drops during installation or operation. This makes them an excellent choice for both indoor and outdoor plumbing systems, where they may be exposed to harsh conditions. Unlike fragile materials like ceramic or glass, PPR fittings maintain their integrity even in the event of minor physical damage.

4. Resistance to Chemical Attack

PPR fittings are resistant to a wide range of chemicals, including acids, alkalis, and salts. This makes them highly suitable for industrial applications or areas with aggressive water treatment chemicals. Their chemical resistance ensures that they will not degrade over time due to exposure to harsh substances.

Tips to Maximize the Lifespan of PPR Fittings

To ensure your PPR fittings last as long as possible, here are a few tips to follow:

- Use high-quality fittings: Always choose fittings from reputable manufacturers to ensure durability and longevity.

- Install fittings correctly: Proper installation is essential for preventing leaks and ensuring the integrity of your system.

- Protect from UV exposure: If installing outdoors, cover PPR pipes to protect them from prolonged UV exposure.

- Check water quality regularly: Use water treatment solutions if necessary to avoid damaging your PPR fittings with harsh chemicals.

- Perform regular inspections: Check for signs of wear and tear, even though PPR fittings require less maintenance than other materials.

Frequently Asked Questions (FAQs)

1. How long do PPR fittings last?

PPR fittings can last up to 50 years or more when installed properly and under ideal conditions, thanks to their corrosion resistance and low maintenance needs.

2. Can PPR fittings be used for hot water systems?

Yes, PPR fittings are designed to handle both hot and cold water systems. They can withstand water temperatures up to 95°C (203°F).

3. Are PPR fittings resistant to corrosion?

Yes, PPR fittings are highly resistant to corrosion, unlike metal pipes, making them ideal for long-term plumbing applications.

4. How do I prevent damage to my PPR fittings in outdoor installations?

To prevent damage from UV exposure, it’s recommended to shield or cover the pipes from direct sunlight. You can also insulate the pipes in cold climates to prevent freezing.

5. Can I install PPR fittings myself?

Yes, installing PPR fittings is relatively simple and can be done by DIY enthusiasts with the right tools, such as a PPR welding machine for fusion.

By understanding the factors that contribute to the durability and longevity of PPR fittings, you can make informed decisions about their use in your plumbing system. With proper installation and maintenance, PPR fittings offer a long-lasting and cost-effective solution for both residential and commercial applications.