IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

In the world of plumbing, construction, and industrial systems, the need for durable, corrosion-free piping systems is more pressing than ever. One material that has stood out in addressing this need is HDPE fittings (High-Density Polyethylene). Known for their incredible resistance to corrosion, HDPE fittings are becoming increasingly popular in various industries as a reliable solution to common piping issues. This article will explore why HDPE fittings are considered the future of corrosion-free piping systems.

What Are HDPE Fittings?

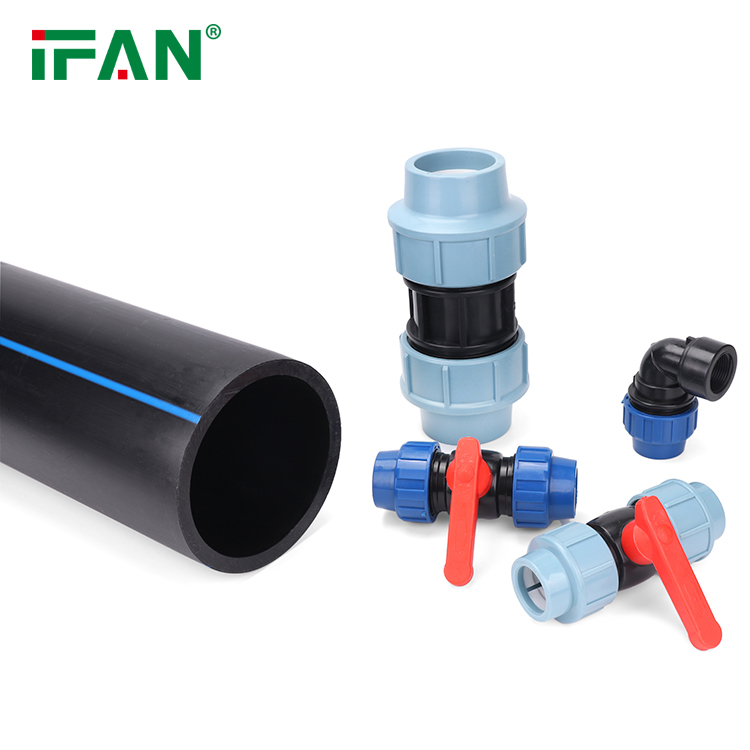

HDPE fittings are components made from High-Density Polyethylene (HDPE), a thermoplastic material that offers excellent strength, flexibility, and resistance to a wide range of chemicals. HDPE fittings are used to connect, redirect, or terminate pipes in systems across various industries, including water treatment, agricultural irrigation, and oil and gas. They come in a variety of shapes and sizes, including elbows, tees, couplings, and flanges.

The Importance of Corrosion-Free Piping Systems

Corrosion is one of the most significant issues faced by traditional piping systems. Materials such as steel and copper are prone to rust, degradation, and damage when exposed to water, chemicals, and environmental factors. In contrast, HDPE fittings are incredibly resistant to corrosion, which makes them an attractive choice for applications in harsh environments. This resistance to corrosion helps prolong the lifespan of the piping system and reduces the need for costly repairs and replacements.

Why HDPE Fittings Are Corrosion-Free

1. Resistance to Chemical Degradation

One of the primary reasons HDPE fittings are considered corrosion-free is their impressive resistance to a wide range of chemicals. Unlike traditional piping materials like PVC or copper, HDPE does not degrade when exposed to acids, bases, or solvents. This chemical resistance makes HDPE ideal for systems that transport aggressive substances like chemicals, wastewater, or oils. As a result, HDPE ensures the longevity of the piping system, even in the harshest of environments.

2. No Risk of Rusting

Traditional metals like copper and steel are prone to rust and corrosion over time, especially when exposed to moisture. Rust not only weakens the structure of the pipes but can also cause blockages and leaks in the system. HDPE fittings, however, are made of a non-corrosive polymer that does not rust or degrade when exposed to water or moisture. This characteristic makes HDPE an ideal choice for water supply and drainage systems, where moisture exposure is constant.

3. UV Resistance

HDPE fittings are inherently resistant to UV degradation, a common issue with other piping materials like PVC. When exposed to the sun’s ultraviolet rays, many plastics can become brittle and lose strength. However, HDPE fittings retain their integrity even under prolonged exposure to UV radiation, making them suitable for outdoor installations. This UV resistance means that HDPE systems last longer without cracking or deteriorating, offering a significant advantage over traditional materials.

4. High-Pressure Resistance

HDPE is not only resistant to corrosion but also exhibits excellent performance under pressure. This makes HDPE fittings ideal for high-pressure systems, such as those found in industrial applications, water treatment facilities, and irrigation systems. Unlike metal pipes that may corrode and weaken under high pressure, HDPE can maintain its strength and performance, even under demanding conditions.

5. Abrasion Resistance

In addition to chemical and UV resistance, HDPE fittings are highly resistant to abrasion. This makes them perfect for use in applications where the pipes may be subjected to wear and tear, such as mining, slurry transport, and agricultural irrigation. The durability of HDPE fittings ensures that the piping system remains functional for a longer period, reducing the likelihood of leaks or system failures caused by abrasive damage.

Environmental Benefits of HDPE Fittings

In today’s environmentally-conscious world, sustainability is a significant factor in choosing piping materials. HDPE is a recyclable material, meaning it can be reused and repurposed at the end of its life cycle. This reduces waste and environmental impact, making HDPE fittings a greener option compared to traditional metals like copper and steel, which are energy-intensive to produce and recycle.

Moreover, HDPE’s lightweight nature reduces the carbon footprint during transportation and installation. The material is easier to handle, requiring less energy to move and install compared to heavier piping materials. As industries shift toward more sustainable practices, HDPE fittings offer an eco-friendly alternative to conventional piping systems.

Cost-Effectiveness of HDPE Fittings

While the initial cost of HDPE fittings may be slightly higher than traditional materials, their long-term cost benefits are undeniable. The durability and corrosion resistance of HDPE mean fewer repairs and replacements over time. Additionally, the ease of installation—due to HDPE’s flexibility and the use of heat fusion for joining—reduces labor costs significantly. Over the lifespan of a system, HDPE’s resistance to degradation and the need for less maintenance result in significant cost savings.

Applications of HDPE Fittings

HDPE fittings are used in a variety of applications across different industries, including:

- Water Treatment: HDPE fittings are used in water distribution systems to prevent rusting and corrosion, ensuring safe, clean water transportation.

- Agriculture: HDPE piping systems are ideal for irrigation systems, where resistance to chemicals and UV degradation is crucial.

- Oil and Gas: In oil and gas operations, HDPE is used to transport chemicals and hydrocarbons without the risk of corrosion.

- Industrial Applications: HDPE is commonly used in industrial plants for chemical transportation, sewage systems, and stormwater drainage.

- Construction: HDPE fittings are used in trenchless technology and underground systems, where flexibility and corrosion resistance are critical.

Conclusion: The Future of Corrosion-Free Piping Systems

As industries continue to demand more durable, cost-effective, and environmentally friendly solutions, HDPE fittings are emerging as the future of corrosion-free piping systems. With their impressive resistance to chemicals, moisture, UV radiation, and abrasion, HDPE fittings are ideal for a wide range of applications, from water supply systems to industrial and agricultural uses. As the world moves toward sustainability and long-lasting solutions, HDPE is paving the way for a new era of piping technology that eliminates the risks associated with traditional materials.

FAQs About HDPE Fittings

- What are HDPE fittings made of?

HDPE fittings are made from High-Density Polyethylene, a thermoplastic polymer known for its strength, flexibility, and resistance to corrosion and chemicals. - Why are HDPE fittings resistant to corrosion?

HDPE fittings are made of a non-corrosive material that does not degrade when exposed to water, chemicals, or moisture, making them ideal for applications that require long-term durability. - Can HDPE fittings be used for high-temperature systems?

HDPE fittings are best suited for systems that operate at lower temperatures. For high-temperature applications, materials like copper or steel are more suitable. - Are HDPE fittings eco-friendly?

Yes, HDPE is a recyclable material, making HDPE fittings an environmentally friendly choice for piping systems. Additionally, HDPE’s durability reduces the need for frequent replacements, further contributing to sustainability. - How long do HDPE fittings last?

HDPE fittings are designed to last for decades, often exceeding 50 years, thanks to their resistance to corrosion, chemicals, and environmental stress.