Introduction

In the world of military logistics and infrastructure, the efficiency and reliability of water supply systems are paramount. One of the standout materials that have gained traction in recent years is Polypropylene Random Copolymer (PPR) pipes. These pipes are increasingly used in various military applications, including water supply and distribution systems. In 2022, the Army’s implementation of PPR pipes has shown remarkable results, particularly in their durability, safety, and efficiency. This article explores the significance of PPR pipes in military operations, the results achieved in 2022, and their overall impact on water supply systems.

Understanding PPR Pipes

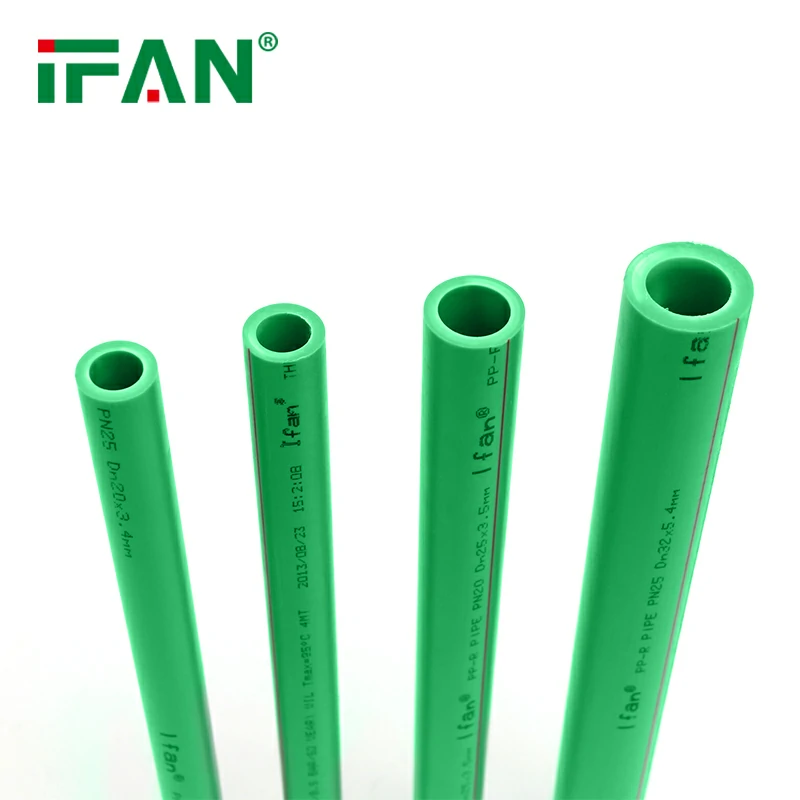

What Are PPR Pipes?

Polypropylene Random Copolymer (PPR) pipes are a type of thermoplastic piping known for their versatility, strength, and resistance to high temperatures and pressures. Made from a specific type of polypropylene, these pipes are designed to handle a variety of applications, including hot and cold water supply systems.

Key Features of PPR Pipes

- High Pressure and Temperature Resistance: PPR pipes can withstand pressures up to 20 bars (approximately 290 psi) and temperatures up to 95°C (203°F), making them suitable for a range of applications, including military use.

- Corrosion Resistance: Unlike metal pipes, PPR pipes do not corrode over time, ensuring that the water remains uncontaminated and safe for consumption.

- Non-Toxic and Safe: PPR pipes are free from harmful chemicals and toxins, making them a safe choice for transporting drinking water.

- Lightweight and Easy to Install: The lightweight nature of PPR pipes simplifies transportation and installation, which is crucial in military operations where time and efficiency are essential.

- Low Maintenance: PPR pipes require minimal maintenance, reducing the long-term costs associated with water supply systems.

The Importance of Water Pipes in Military Operations

Ensuring Safe Drinking Water

In military operations, access to safe drinking water is critical for the health and well-being of personnel. PPR pipes play a vital role in ensuring that clean water is delivered efficiently and safely. Their non-toxic properties and resistance to leaching make them an ideal choice for military water supply systems.

Efficiency in Water Distribution

Efficient water distribution is crucial in military settings, where the demand for water can fluctuate significantly. PPR pipes feature smooth inner surfaces that minimize friction, allowing for optimal water flow. This efficiency is particularly important during training exercises and deployments, where access to water can be limited.

Environmental Considerations

Sustainable practices are becoming increasingly important in military logistics. PPR pipes are recyclable and have a long lifespan, contributing to reduced environmental impact. Their durability and low maintenance requirements also mean fewer resources are needed for repairs and replacements over time.

Drumming Results 2022: The Impact of PPR Pipes

Overview of Drumming Results

In 2022, the Army conducted extensive evaluations of PPR pipes in various applications, focusing on their performance in water supply systems. The results demonstrated significant improvements in efficiency, safety, and reliability compared to traditional piping materials.

Key Findings

- Increased Water Supply Reliability: The use of PPR pipes led to a marked increase in the reliability of water supply systems. This improvement was particularly evident in remote locations where access to clean water was previously a challenge.

- Reduced Maintenance Costs: The durability of PPR pipes resulted in lower maintenance costs over time. Military installations reported a significant decrease in the frequency of repairs and replacements, allowing resources to be allocated to other critical areas.

- Enhanced Safety Standards: The non-toxic nature of PPR pipes ensured that the water supplied was safe for consumption. This aspect is particularly crucial in military settings, where health and safety are paramount.

- Improved Installation Efficiency: The lightweight design of PPR pipes facilitated quicker and more efficient installations. Military engineers reported reduced installation times, which is vital during rapid deployment scenarios.

- Positive Environmental Impact: The recyclability of PPR pipes aligns with the military’s commitment to sustainability. The findings highlighted a reduction in environmental impact due to the lower frequency of replacements and repairs.

Applications of PPR Pipes in Military Settings

Water Supply Systems

PPR pipes are predominantly used in military water supply systems, ensuring that personnel have access to clean and safe drinking water. Their ability to handle high pressures and temperatures makes them suitable for various applications, including water treatment facilities and distribution networks.

Field Operations

During field operations, the reliability of water supply systems is critical. PPR pipes can be quickly deployed in temporary setups, providing soldiers with immediate access to water. Their lightweight nature and ease of installation make them ideal for rapid response scenarios.

Training Facilities

Military training facilities require robust water supply systems to support various activities. PPR pipes have been successfully implemented in these facilities, ensuring that trainees have access to safe drinking water and other necessary resources.

Humanitarian Missions

In addition to military operations, PPR pipes are also used in humanitarian missions where clean water supply is essential. Their reliability and safety make them an excellent choice for disaster relief efforts and other humanitarian initiatives.

Installation and Maintenance of PPR Pipes

Installation Process

Installing PPR pipes involves several key steps:

- Planning and Design: Before installation, it is essential to plan the layout of the piping system, including determining the length of the pipe needed and the location of fittings.

- Cutting and Joining: PPR pipes can be easily cut to the desired length using a pipe cutter. Heat fusion is commonly used for joining pipes, ensuring a secure, leak-proof connection.

- Testing the System: After installation, it is crucial to test the system for leaks and ensure that it can handle the required pressure. This step is vital to ensure the longevity and reliability of the water supply system.

Maintenance Requirements

PPR pipes require minimal maintenance due to their corrosion resistance and durability. Regular inspections are recommended to ensure the system remains leak-free and efficient. This low maintenance requirement is particularly advantageous for military operations, where resources may be limited.

Conclusion

The implementation of Army PPR pipes in 2022 has demonstrated significant advancements in the efficiency, safety, and reliability of military water supply systems. With their ability to withstand high pressures and temperatures, PPR pipes have become an essential component in ensuring that personnel have access to clean and safe drinking water. As the military continues to seek innovative solutions for water supply challenges, PPR pipes will undoubtedly play a crucial role in future operations.

Frequently Asked Questions (FAQs)

1. What are PPR pipes used for in military applications?

PPR pipes are primarily used for water supply systems in military settings, ensuring access to clean and safe drinking water. They are also used in field operations, training facilities, and humanitarian missions.

2. How do PPR pipes compare to traditional piping materials?

PPR pipes offer several advantages over traditional materials, including corrosion resistance, lower maintenance costs, and a lightweight design that simplifies installation.

3. What is the maximum pressure that PPR pipes can handle?

PPR pipes can withstand pressures up to 20 bars (approximately 290 psi), making them suitable for high-pressure water supply applications.

4. Are PPR pipes safe for transporting drinking water?

Yes, PPR pipes are non-toxic and free from harmful chemicals, making them a safe choice for transporting drinking water.

5. What maintenance do PPR pipes require?

PPR pipes require minimal maintenance due to their durability and corrosion resistance. Regular inspections are recommended to ensure the system remains leak-free and efficient.