A Guide to Understanding the Different Types of HDPE Fittings

HDPE fittings are essential components in pipe and tubing networks. They ensure the proper control and flow of fluids and gases. High-density polyethylene (HDPE) is a thermoplastic material that has unique properties, which are why it is widely used in various industrial applications. HDPE fittings come in different types, sizes, shapes, and configurations.

In this guide, we will explore the different types of HDPE fittings and their features. We will also look at their advantages and value proposition.

- Butt fusion fittings

Butt fusion fittings form a permanent and leak-proof connection between two pipes through thermal melting. This type of fitting is popular due to its ease of use, cost-effectiveness, and long-lasting durability.

- Electrofusion fittings

Electrofusion fittings make use of electrical energy to melt and fuse the fitting onto the pipe. They are popular because they are quick, easy, and reliable.

- Compression fittings

Compression fittings consist of a ring that squeezes tightly over the pipe while connecting two pipes. They are used for low-pressure applications and are easy to install.

- Mechanical fittings

Mechanical fittings use a mechanical grip to hold the fitting and the pipe together. They are versatile, easy to install, and cost-effective.

- Flange fittings

Flange fittings connect two pipes through a flange that has holes drilled for bolts. They are used in high-pressure applications and can withstand extreme temperatures.

Advantages and value proposition of HDPE fittings

HDPE fittings have several advantages:

- High resistance to corrosion and chemicals

- Lightweight and flexible, making them easy to install

- Leak-proof and reliable

- Long-lasting durability

- Cost-effective

- Ability to tolerate high or low temperatures

- Environmentally friendly, as they can be recycled

HDPE fittings offer value to users:

- Cost savings due to long-term durability and low maintenance

- Lower energy costs due to leak-proof connections

- Increased productivity due to quick and easy installation

- Improved safety due to their resistance to corrosion and chemicals

Conclusion

HDPE fittings are essential components of piping and tubing networks. Understanding the different types of fittings and their features can help users to choose the right fittings for their specific needs. HDPE fittings offer users invaluable advantages, such as long-lasting durability, leak-proof connections, and cost savings. By selecting HDPE fittings, users benefit from improved safety, increased productivity, and reduced energy costs.

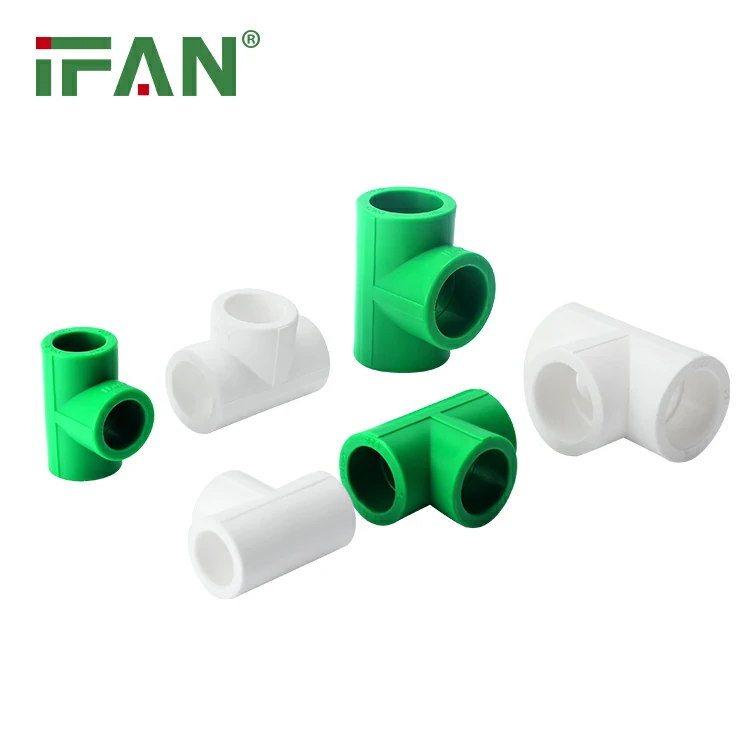

IFAN factory started in 1993. And IFAN has workshop 120000 square meter with 610 staff. IFAN can design and produce all plumbing pipe and fitting include PPR,PVC,CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting ,brass fitting, brass ball valve ,heating system , gas system , sanitary faucets and hose, In the past 30 Years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory use best materials to produce high quality pipe and fittings with automatic production line and high tech quality control machines. The most important,IFAN can guarantee that all pipes and fittings manufactured by IFAN are qualified.

Free Sample(Click Here to Get Free Sample)