The Safety of Using HDPE Fittings in Industrial and Municipal Applications

When it comes to industrial and municipal applications, safety and durability are key considerations. That’s why HDPE fittings have become a popular choice for professionals in various industries, including water management, gas distribution, and mining. In this article, we’ll explore the unique features and benefits of HDPE fittings, as well as their value in industrial and municipal applications.

What are HDPE Fittings?

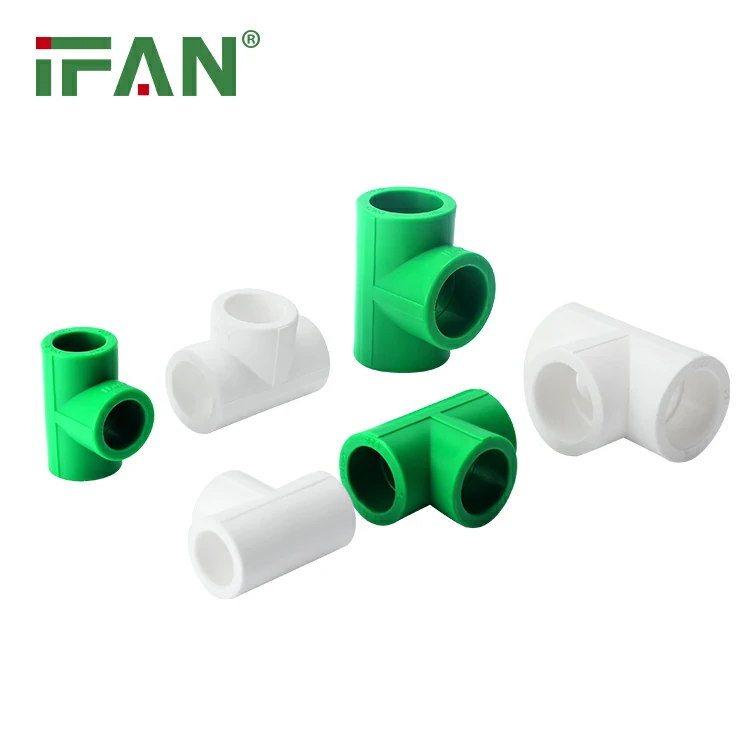

High-density polyethylene (HDPE) fittings are molded parts made from high-quality plastic resin. They are designed to connect HDPE pipes and provide secure, leak-proof connections. HDPE fittings come in a variety of shapes and sizes, including couplers, elbows, tees, reducers, and end caps. They are lightweight, corrosion-resistant, and easy to work with, making them a popular choice for many different applications.

The Advantages of HDPE Fittings

One of the main advantages of HDPE fittings is their durability. They are designed to withstand extreme temperatures, pressure, and chemical exposure, making them ideal for use in a wide range of industrial and municipal applications. HDPE fittings are also resistant to corrosion and abrasion, and they can last for decades without requiring replacement.

Another key advantage of HDPE fittings is their flexibility. Unlike other materials, HDPE can bend and stretch without cracking or breaking. This makes it ideal for use in applications where there may be ground movement or other environmental factors that could affect the pipes. In addition, HDPE fittings can be easily installed using a variety of methods, including electrofusion, butt fusion, and mechanical connections.

The Value of HDPE Fittings in Industrial and Municipal Applications

HDPE fittings have become a go-to choice for professionals in various industries thanks to their unique features and benefits. For example, in water management applications, HDPE fittings are often used to connect pipes for drinking water, wastewater, and stormwater systems. These systems require high-quality, durable materials that can withstand exposure to various chemicals, contaminants, and environmental factors. HDPE fittings deliver that reliability, giving water management professionals peace of mind that their systems will function safely and effectively.

In gas distribution applications, HDPE fittings are used to connect pipes that transport natural gas and other gases. These systems require high-pressure, leak-proof connections that can withstand changes in temperature and pressure. HDPE fittings deliver a secure, long-lasting connection that can reduce the risk of leaks and other safety hazards associated with gas distribution systems.

Mining operations also benefit greatly from HDPE fittings, which are used to connect pipes that transport water, slurry, and other materials. These systems require materials that can withstand the wear and tear of harsh mining environments, and HDPE fittings deliver that durability. They are resistant to abrasion, corrosion, and chemical exposure, making them ideal for use in mining applications where safety and performance are critical.

Take Action

If you’re looking for reliable, durable, and flexible fittings for your next industrial or municipal project, consider HDPE fittings. These versatile fittings provide a secure, leak-proof connection that can withstand extreme temperatures, pressure, and chemical exposure. They are easy to work with, and they can be installed using a variety of methods. Contact your local supplier today to learn more about how HDPE fittings can benefit your project.

IFAN factory started in 1993. And IFAN has workshop 120000 square meter with 610 staff. IFAN can design and produce all plumbing pipe and fitting include PPR,PVC,CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting ,brass fitting, brass ball valve ,heating system , gas system , sanitary faucets and hose, In the past 30 Years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory use best materials to produce high quality pipe and fittings with automatic production line and high tech quality control machines. The most important,IFAN can guarantee that all pipes and fittings manufactured by IFAN are qualified.

Free Sample(Click Here to Get Free Sample)