The Environmental Benefits of Using HDPE Fittings in Construction

Construction is a vital industry, contributing enormously to global economic growth. However, it’s also a significant contributor to environmental degradation. The extensive use of non-biodegradable and harmful materials not only increases landfills but also poses a significant threat to the environment. In the construction industry, High-Density Polyethylene (HDPE) Fittings have been introduced as a reliable and environmentally friendly alternative. In this article, we will discuss the environmental benefits of using HDPE Fittings in construction.

HDPE Fittings are made from a strong plastic material that is lightweight yet durable. The material is recyclable, reduces material wastage and is resistant to weathering, meaning it can last for decades. These fittings also do not leach any harmful substances, making it an eco-friendly solution. By using HDPE Fittings, construction waste can be reduced drastically, minimizing the negative environmental impact of construction activities.

One of the primary advantages of HDPE Fittings is that it is highly resistant to chemicals and corrosion. This property ensures that HDPE Fittings have a long life span, reducing the need for frequent replacements and repairs. The inert nature of HDPE Fittings ensures that they do not rust, corrode, or wear down over time, making them ideal for underground and retaining applications. This factor ultimately saves construction companies and property owners money on replacement, repair and maintenance costs.

The installation of HDPE Fittings is also seamless, as they can be easily installed using heat fusion. This method eliminates the need for solvent-based glues, adhesives, and primers that can release harmful chemicals during installation. HDPE Fittings are safer than traditional metal fittings as they cannot corrode or rust, further enhancing their longevity and environmental friendliness.

Another advantage of HDPE Fittings is their energy-efficient nature. HDPE Fittings are lightweight and easy to transport due to their low density, which reduces shipping costs. This low transportation cost means less fuel is needed, reducing greenhouse gas emissions and overall carbon footprint. HDPE Fittings are also energy-efficient to produce because they require less energy to manufacture, further reducing their environmental impact.

In conclusion, HDPE Fittings are the perfect solution for constructing buildings that are environmentally friendly. HDPE Fittings use recyclable materials, have a long life span, resist corrosion and chemicals, are easy to install and energy-efficient. By investing in HDPE Fittings, construction companies, property owners, and general contractors can ensure they are doing their part to protect the environment by reducing waste and using eco-friendly materials. Let’s make a positive change by adopting HDPE Fittings in construction practices, together.

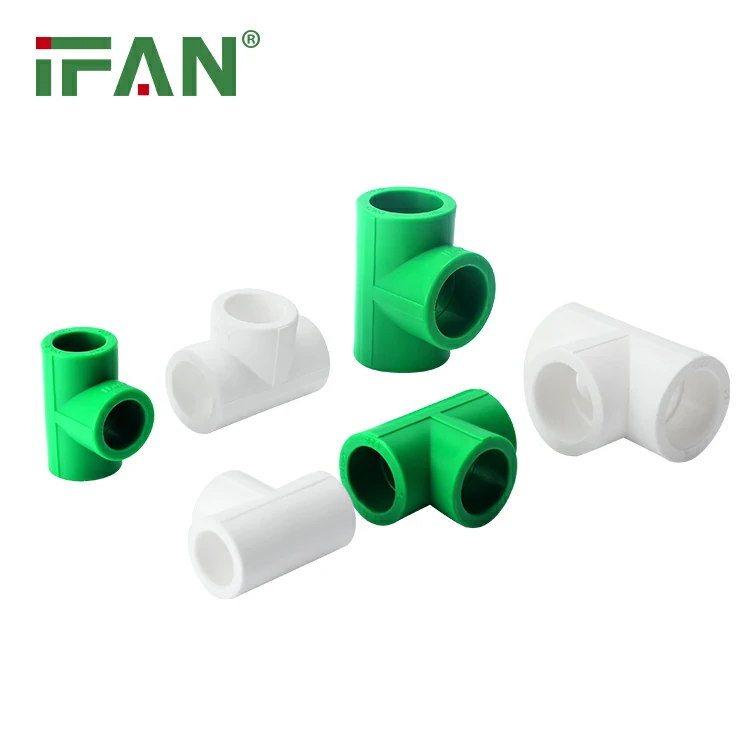

IFAN factory started in 1993. And IFAN has workshop 120000 square meter with 610 staff. IFAN can design and produce all plumbing pipe and fitting include PPR,PVC,CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting ,brass fitting, brass ball valve ,heating system , gas system , sanitary faucets and hose, In the past 30 Years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory use best materials to produce high quality pipe and fittings with automatic production line and high tech quality control machines. The most important,IFAN can guarantee that all pipes and fittings manufactured by IFAN are qualified.

Free Sample(Click Here to Get Free Sample)