Introduction

PPR (Polypropylene Random Copolymer) pipes and fittings offer numerous benefits such as chemical resistance, durability, and longevity. However, one of the most significant benefits of PPR fittings is their cost-effectiveness in the long run. This article will discuss the cost-effectiveness of PPR fittings in detail and show why they are an excellent investment for any building.

The up-front cost of PPR fittings

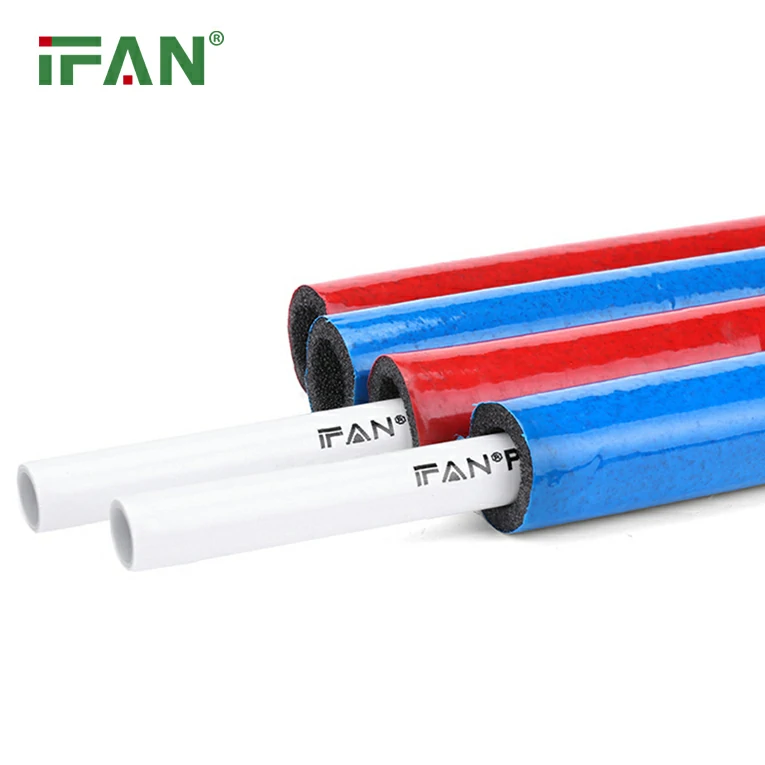

PPR fittings’ initial cost is often higher than traditional copper or PVC piping systems. However, it’s essential to consider the long-term savings that PPR fittings provide when calculating the overall cost of a building’s plumbing system. The cost of PPR fittings may vary depending on the manufacturer, dimensions, and fittings’ type. Nonetheless, the cost per fitting is generally higher than traditional fittings.

The Benefits of PPR fittings

PPR fittings offer various benefits that make them a cost-effective option in the long run. Firstly, they have a longer lifespan compared to traditional piping systems. PPR fittings can last up to 50 years, making them an ideal investment for any construction project. Additionally, their resistance to corrosion and chemicals ensures that they maintain their structural integrity over time. They are also easy to install, reducing labor costs, and their lightweight nature makes them easier to transport.

The Cost Savings in the Long Run

The initial cost of PPR fittings may discourage some people from using these fittings in their construction projects. However, when you consider the savings over time, it becomes evident that PPR fittings are a cost-effective investment. As previously mentioned, PPR fittings have a longer lifespan. This means that the cost of replacing traditional fittings over time is significantly higher than the cost of investing in PPR fittings in the beginning.

Moreover, PPR fittings do not require maintenance, reducing operational costs. Traditional piping systems may leak and require frequent repairs, meaning higher labor costs and material. PPR fittings do not corrode, making them ideal for buildings in coastal areas, where saltwater corrosion is a concern.

Conclusion

Given the above, it is clear that PPR fittings can provide significant cost savings in the long run. While their initial cost may be higher than traditional fittings, the lifespan and lack of maintenance make them a cost-effective option in the long run. Given their numerous benefits, such as durability, resistance to corrosion, and ease of installation, PPR fittings are an excellent investment for any construction project. Building owners and contractors should consider PPR fittings when choosing a cost-effective and dependable piping system for their structures.