The Importance of Properly Insulated PPR Fittings in Cold Climates

Introduction

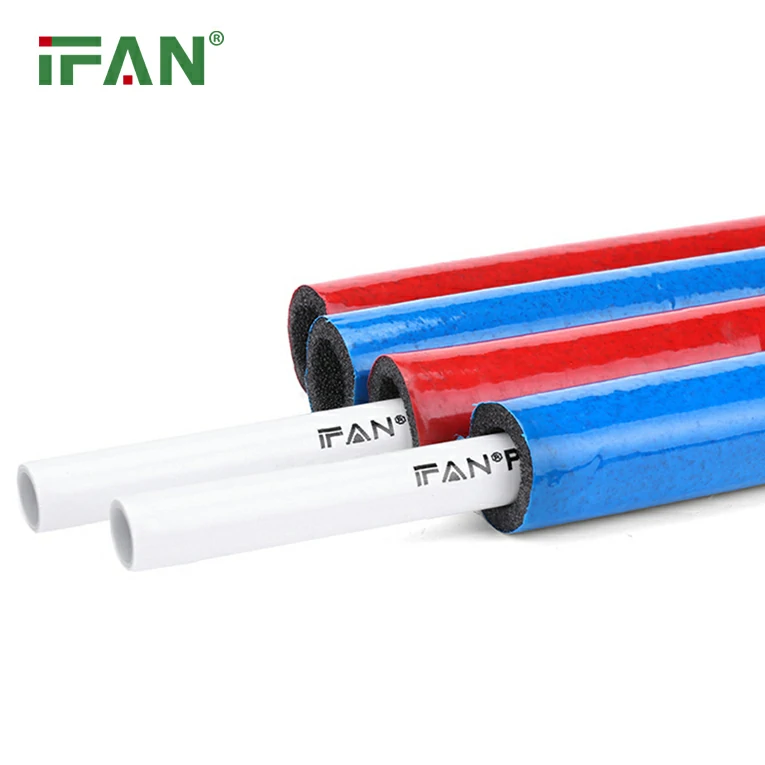

In cold climates, properly insulated PPR fittings play a crucial role in maintaining the functionality and efficiency of plumbing systems. PPR fittings, made from polypropylene random copolymer, provide excellent insulation properties when properly installed. In this article, we will explore the importance of insulation for PPR fittings in cold climates and how it ensures the integrity and reliability of plumbing systems. Let’s delve into the details of why proper insulation is essential for PPR fittings in cold climate applications.

1. Freeze Protection

One of the primary concerns in cold climates is the freezing of water inside the plumbing system. When water freezes, it expands and can cause pipes and fittings to crack or burst. Properly insulated PPR fittings help prevent freezing by maintaining a consistent temperature within the system. Insulation acts as a barrier, reducing heat loss and protecting the fittings from extreme cold temperatures. By preventing freezing, insulation ensures the continuous flow of water and minimizes the risk of costly repairs or water damage due to pipe or fitting failure.

2. Energy Efficiency

In cold climates, maintaining a comfortable indoor temperature is essential. Proper insulation of PPR fittings helps conserve heat within the plumbing system, resulting in energy efficiency. Insulated fittings prevent heat loss, allowing the hot water to retain its temperature as it travels through the pipes. This energy efficiency not only reduces heating costs but also provides immediate access to hot water, minimizing the need for additional energy consumption to heat cold water. Properly insulated PPR fittings contribute to sustainable and cost-effective plumbing systems in cold climates.

3. Condensation Control

Cold climates often experience significant temperature variations, leading to condensation inside plumbing systems. Condensation can be problematic as it can cause water damage, mold growth, and corrosion of fittings and pipes. Proper insulation of PPR fittings helps control condensation by maintaining a consistent temperature on the exterior surface. The insulation layer prevents the formation of condensation, protecting the fittings from moisture-related issues. By controlling condensation, insulation ensures the longevity and reliability of the plumbing system in cold climates.

4. Thermal Expansion Control

Extreme cold temperatures in cold climates can cause thermal contraction and expansion of pipes and fittings. Proper insulation of PPR fittings helps control thermal expansion, ensuring the stability and integrity of the plumbing system. Insulation minimizes stress on the fittings, reducing the risk of cracks or leaks due to temperature fluctuations. By providing thermal expansion control, insulation preserves the functionality and longevity of the fittings, even in harsh cold weather conditions.

5. Protection from Freezing Ground

In cold climates, the ground can freeze, which poses a risk to the integrity of plumbing systems. Proper insulation of PPR fittings protects them from the freezing ground. Insulation acts as a thermal barrier, preventing the cold from penetrating the fittings and causing freezing or damage. This protection ensures that the plumbing system remains operational and leak-free, even when exposed to frozen ground conditions.

6. Easy Installation and Retrofits

Insulation for PPR fittings is available in various forms, including pre-insulated options and retrofittable insulation sleeves. These options make installation and retrofits easy in cold climates. Pre-insulated fittings come with factory-applied insulation, saving time and effort during installation. Retrofittable insulation sleeves can be easily added to existing fittings, providing insulation in already installed plumbing systems. The availability of these insulation options makes it convenient to ensure proper insulation for PPR fittings in both new constructions and existing buildings.

Conclusion

Proper insulation of PPR fittings is essential in cold climates to protect the plumbing system from freezing, maintain energy efficiency, control condensation, manage thermal expansion, safeguard against freezing ground conditions, and facilitate easy installation and retrofits. By ensuring proper insulation, homeowners and businesses can have confidence in the durability, reliability, and functionality of their plumbing systems, even in extreme cold weather. Insulated PPR fittings contribute to efficient and trouble-free plumbing operations, reducing the risk of damage, and providing peace of mind in cold climate applications.