Are PPR pipe fittings suitable for industrial applications?

PPR (Polypropylene Random Copolymer) pipe fittings are suitable for a wide range of industrial applications. Here are some key points regarding the suitability of PPR pipe fittings for industrial use:

1. Chemical Resistance: PPR pipe fittings exhibit excellent resistance to various chemicals, making them suitable for industrial applications where exposure to chemicals is common. They can withstand acids, alkalis, organic solvents, and other chemical compounds without degradation.

2. Corrosion Resistance: PPR pipe fittings are not susceptible to corrosion or rust, unlike metal fittings. Their corrosion resistance ensures durability and longevity, making them suitable for industrial environments.

3. Heat Resistance: PPR pipe fittings can withstand high temperatures, making them suitable for industrial applications that involve hot water or steam. They can handle continuous use at temperatures up to 203°F (95°C).

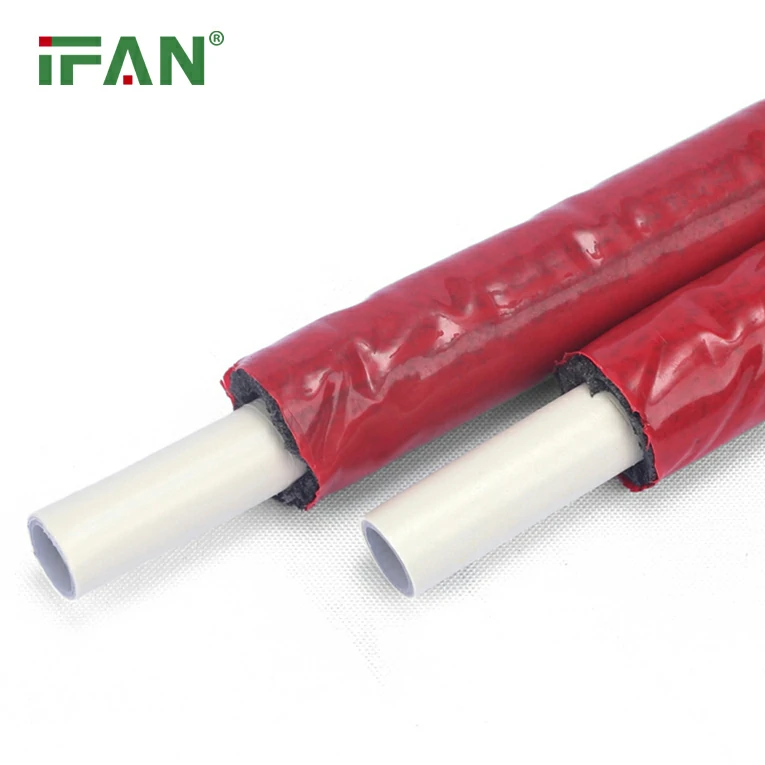

4. Low Thermal Conductivity: PPR pipe fittings have low thermal conductivity, which helps maintain the temperature of the fluids being transported in industrial applications. This property improves energy efficiency and reduces heat loss.

5. Easy Installation: PPR pipe fittings are lightweight and easy to handle, allowing for quick and efficient installation in industrial settings. They can be joined using socket fusion, electrofusion, or mechanical connections, depending on the specific requirements of the project.

6. Mechanical Strength: PPR pipe fittings have good mechanical strength, allowing them to withstand the rigors of industrial environments. They are resistant to impact and can handle the stresses of normal operation.

7. Longevity: With proper installation and maintenance, PPR pipe fittings have a long lifespan in industrial applications. Their resistance to chemicals, corrosion, and heat ensures reliable performance and a reduced need for frequent replacements.

PPR pipe fittings offer several advantages that make them suitable for a wide range of industrial applications, including their chemical resistance, corrosion resistance, heat resistance, low thermal conductivity, ease of installation, mechanical strength, and longevity.