Maintenance Tips for PPR Fiberglass Pipes: Ensuring Longevity

Introduction

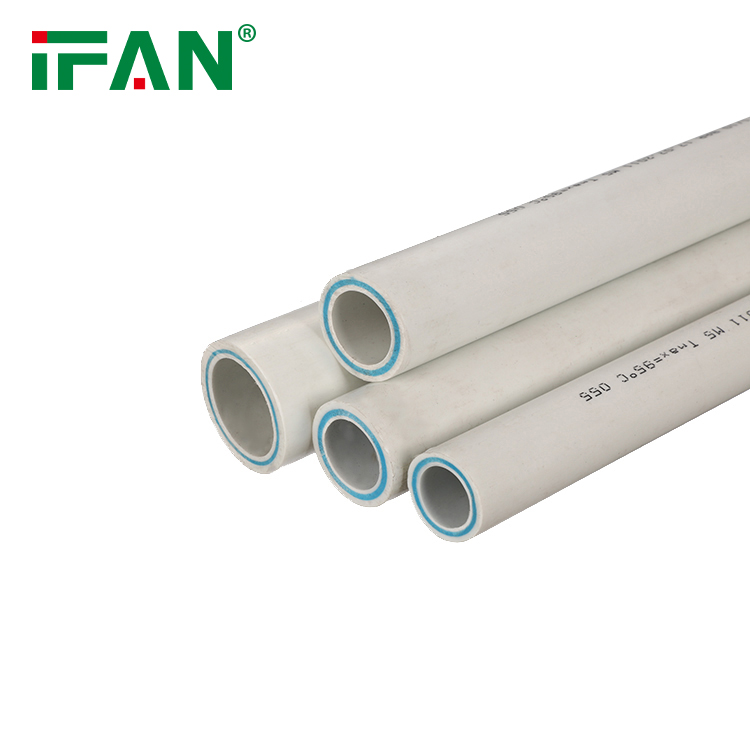

PPR (Polypropylene Random Copolymer) fiberglass pipes are known for their durability and long service life. However, proper maintenance is essential to ensure the continued performance and longevity of these pipes. In this article, we will explore some important maintenance tips for PPR fiberglass pipes. Let’s break down each section into separate headings.

1. Regular Inspection

Regularly inspecting PPR fiberglass pipes is crucial to identify any signs of damage, leaks, or deterioration. Inspect the pipes visually for cracks, discoloration, or bulging. Check the joints, fittings, and connections for any signs of leakage. Pay attention to any unusual noises or vibrations that may indicate a problem within the system. Early detection of issues can prevent major damage and costly repairs in the future.

2. Cleaning and Flushing

Periodic cleaning and flushing of PPR fiberglass pipes help remove any built-up debris, scale, or sediment that may accumulate over time. Use appropriate cleaning solutions and equipment recommended by the pipe manufacturer to ensure effective cleaning without causing any damage. Flushing the pipes with clean water helps maintain optimal flow and prevents clogging. Regular cleaning and flushing contribute to the longevity and efficiency of the piping system.

3. Temperature and Pressure Monitoring

Monitoring the temperature and pressure of PPR fiberglass pipes is essential to prevent excessive stress or damage. Ensure that the pipes are operating within the recommended temperature and pressure limits specified by the manufacturer. Sudden fluctuations or prolonged exposure to extreme conditions can compromise the integrity of the pipes. Install temperature and pressure gauges at appropriate locations to monitor and adjust the system accordingly.

4. Insulation and Protection

Proper insulation and protection of PPR fiberglass pipes are important to safeguard them from external factors that can cause damage or degradation. Insulate pipes that are exposed to extreme temperatures to prevent freezing or overheating. Protect the pipes from physical damage, such as impact or abrasion, by using suitable covers or barriers. Ensure that the pipes are adequately supported to prevent sagging or stress on the joints.

5. Chemical Compatibility

Consider the chemical compatibility of PPR fiberglass pipes with the fluids or substances they transport. Ensure that the pipes are not exposed to chemicals or solutions that may cause degradation or corrosion. Consult with chemical compatibility charts or experts to determine the suitability of the pipes for specific applications. If necessary, use appropriate protective coatings or linings to enhance chemical resistance.

6. Professional Maintenance and Repairs

Engage professional maintenance services for regular inspections, repairs, and maintenance of PPR fiberglass pipes. Experienced technicians can provide comprehensive assessments and address any issues promptly. If repairs are needed, ensure that only approved materials and techniques are used. Avoid using adhesives or sealants that may weaken the pipes or compromise their chemical resistance properties.

Conclusion

Proper maintenance is vital to ensure the longevity and optimal performance of PPR fiberglass pipes. Regular inspection, cleaning, and flushing help prevent issues such as leaks, clogs, or degradation. Monitoring temperature and pressure, insulating and protecting the pipes, and considering chemical compatibility are essential steps in maintaining their integrity. Engaging professional maintenance services ensures that any problems are promptly addressed with approved repair methods. By following these maintenance tips, industries can maximize the lifespan and reliability of their PPR fiberglass pipe systems, minimizing downtime and reducing overall maintenance costs.