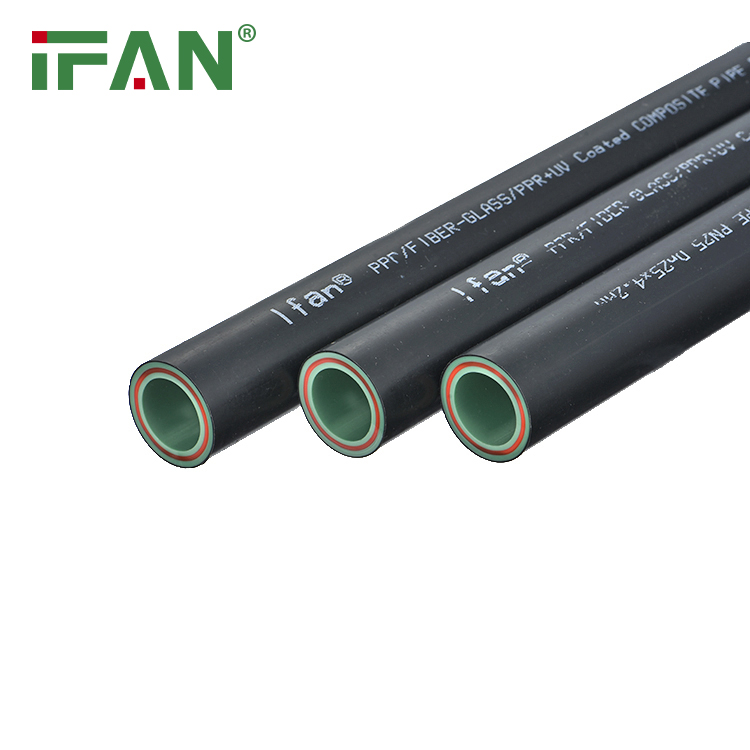

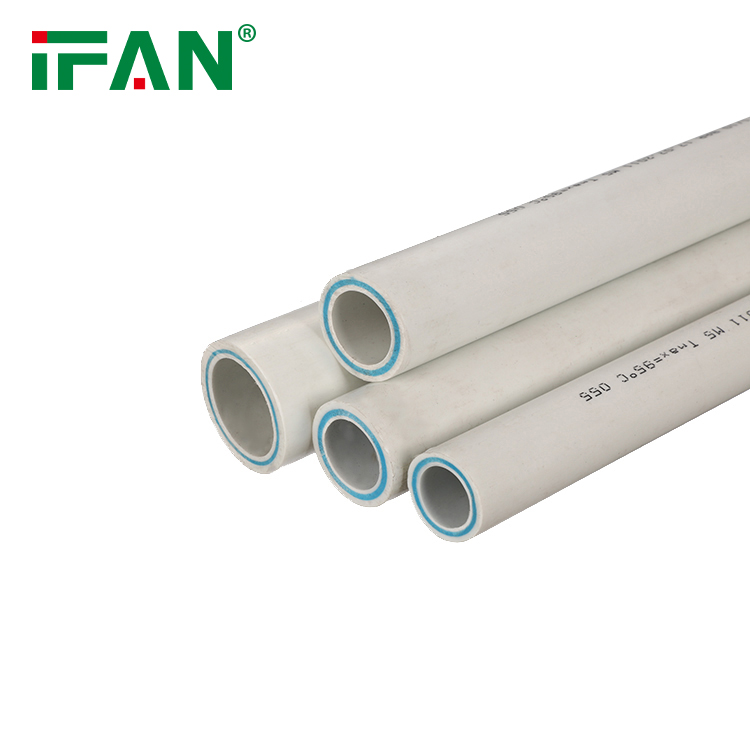

How PPR Fiberglass Pipes Ensure Efficient Water Distribution

PPR (Polypropylene Random Copolymer) fiberglass pipes have gained significant popularity in the field of water distribution systems due to their unique characteristics and advantages. In this article, we will explore the key reasons why PPR fiberglass pipes are used to ensure efficient water distribution. Let’s break down each section into separate headings.

1. High Flow Capacity

One of the primary advantages of PPR fiberglass pipes is their high flow capacity. These pipes have a smooth inner surface that minimizes friction, allowing water to flow freely and efficiently. The smooth surface also prevents the build-up of sediments and deposits, ensuring a consistent water flow over the long term. The high flow capacity of PPR fiberglass pipes reduces the pressure drop and ensures efficient water distribution throughout the system.

2. Corrosion Resistance

PPR fiberglass pipes are highly resistant to corrosion, making them ideal for water distribution systems. Unlike metal pipes that can corrode over time, PPR fiberglass pipes remain unaffected by the corrosive properties of water. This corrosion resistance ensures the integrity of the pipes and prevents leakage or contamination of the water supply. The long lifespan of PPR fiberglass pipes reduces the need for frequent repairs or replacements, contributing to efficient water distribution.

3. Thermal Stability

Efficient water distribution systems require pipes that can withstand varying temperatures without compromising performance. PPR fiberglass pipes exhibit excellent thermal stability, allowing them to handle hot and cold water with ease. These pipes can withstand high temperatures without deforming or deteriorating, ensuring a consistent and reliable water distribution network. The thermal stability of PPR fiberglass pipes minimizes the risk of pipe bursts or leaks due to temperature fluctuations, enhancing the efficiency of the water distribution system.

4. Leak-proof Joints

The joints between pipes play a crucial role in ensuring efficient water distribution. PPR fiberglass pipes utilize heat fusion technology to create leak-proof joints. The ends of the pipes are heated and fused together, forming a strong and seamless connection. This fusion eliminates potential weak spots or leakage points commonly found in traditional pipe joints. The leak-proof joints of PPR fiberglass pipes ensure a continuous and uninterrupted water flow, enhancing the efficiency of the water distribution system.

5. Lightweight and Easy Installation

PPR fiberglass pipes are lightweight compared to traditional materials like metal or PVC. This lightweight nature simplifies the installation process and reduces labor and equipment requirements. The ease of installation translates into time and cost savings, contributing to efficient water distribution system implementation. The lightweight nature of PPR fiberglass pipes also reduces transportation costs and simplifies handling during the installation process.

6. Resistance to Scaling and Chemicals

Scaling is a common issue in water distribution systems, leading to reduced flow capacity and efficiency. PPR fiberglass pipes have a smooth inner surface that resists scaling, preventing the build-up of mineral deposits and ensuring a consistent water flow. Additionally, PPR fiberglass pipes exhibit excellent resistance to chemicals, preventing degradation or damage caused by water treatment additives or contaminants. The resistance to scaling and chemicals enhances the efficiency and longevity of the water distribution system.

Conclusion

In conclusion, PPR fiberglass pipes offer several advantages that ensure efficient water distribution. Their high flow capacity, corrosion resistance, thermal stability, leak-proof joints, lightweight nature, resistance to scaling and chemicals, all contribute to the reliability and efficiency of water distribution systems. By utilizing PPR fiberglass pipes, the water distribution process becomes more efficient, ensuring a consistent and reliable water supply for various applications