Introduction

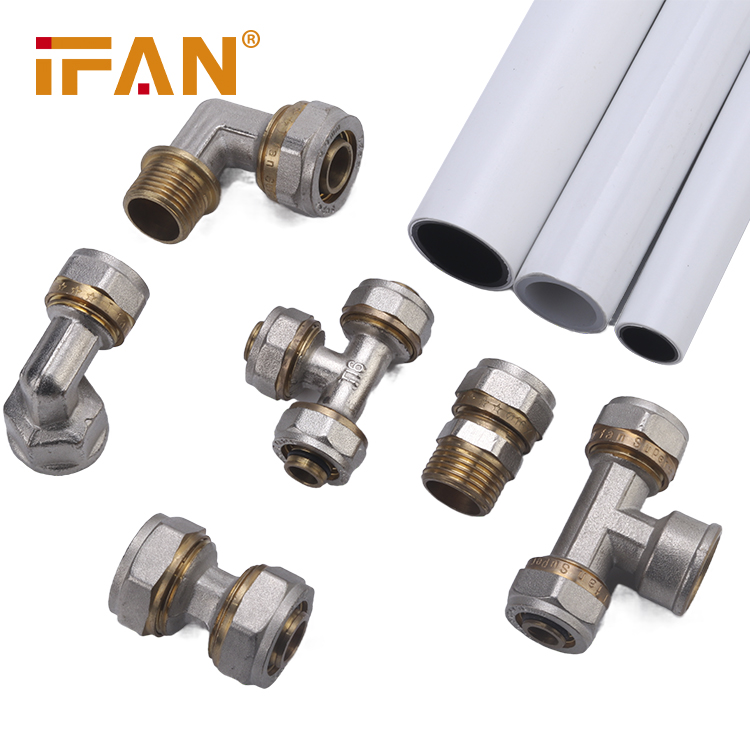

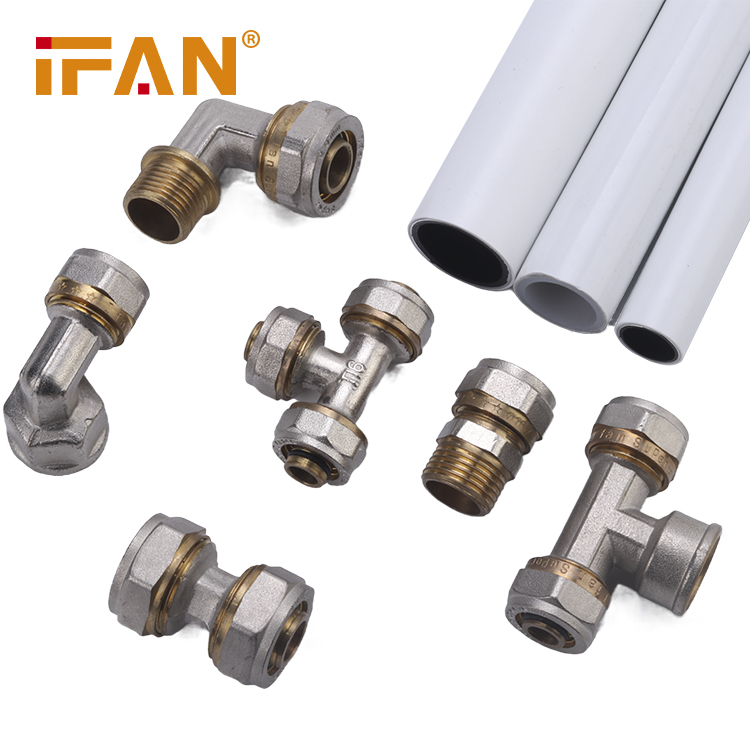

Compression fittings are commonly used in plumbing applications to connect pipes or tubing without the need for soldering, welding, or specialized tools. They offer a secure and reliable connection by compressing a ring or ferrule onto the pipe, creating a tight seal. In this article, we will explore the advantages and considerations of using compression fittings for plumbing.

Advantages of Compression Fittings

- Versatility: Compression fittings are highly versatile and can be used with various types of pipes and tubing, including copper, PEX, PVC, and CPVC. This flexibility allows for easy installation and connection of different plumbing materials, making compression fittings suitable for a wide range of plumbing applications.

- No Heat or Flame Required: Unlike soldering or welding techniques, compression fittings do not require heat or an open flame. This eliminates the risks associated with flames, such as fire hazards or damage to surrounding materials. It also makes compression fittings a safer option, especially in tight spaces or areas where open flames are not allowed.

- Easy Installation and Repairs: Compression fittings are relatively easy to install and repair, making them a convenient option for DIY enthusiasts or professionals. The connection process typically involves sliding the compression nut and ferrule onto the pipe, inserting the pipe into the fitting, and tightening the nut to compress the ferrule onto the pipe. This simplicity allows for quick and efficient installation or repair work.

- Adjustable and Reusable: Compression fittings offer adjustability during installation, allowing for minor adjustments or corrections if needed. The compression nut can be loosened and tightened as required to achieve the desired fit. Additionally, compression fittings are reusable, meaning they can be disassembled and reassembled multiple times without compromising the integrity of the fitting or pipe.

- Wide Range of Sizes and Configurations: Compression fittings are available in a wide range of sizes and configurations to suit various plumbing needs. Whether it’s connecting different pipe materials, transitioning between pipe sizes, or accommodating different connection angles, compression fittings offer a diverse selection to meet specific requirements.

Considerations for Compression Fittings

- Potential for Leaks: While compression fittings generally provide a reliable seal, there is still a potential for leaks if not installed correctly. It is crucial to follow proper installation techniques, such as ensuring the pipe is cut cleanly and squarely, applying the appropriate amount of torque to the compression nut, and inspecting for any signs of leakage after installation. Adequate tightening of the compression nut is essential to achieve a leak-free connection.

- Limited Use with Soft Pipes: Compression fittings may not be suitable for use with certain soft pipe materials, such as polyethylene (PE) or polybutylene (PB). These types of pipes are more susceptible to deformation or damage during the compression process. It is important to consult with the manufacturer or a plumbing professional to determine the compatibility of compression fittings with specific pipe materials.

- Space Requirements: Compression fittings require some additional space for the compression nut and ferrule to be installed and tightened onto the pipe. In tight or confined spaces, this can pose challenges and may limit the use of compression fittings. It is essential to consider the available space and accessibility when deciding whether compression fittings are suitable for a particular plumbing application.

- Cost: While compression fittings are generally cost-effective, they may be slightly more expensive than other connection methods, such as soldering or crimping. The cost difference is often justified by the convenience, versatility, and ease of installation that compression fittings offer.

Conclusion

Compression fittings are a reliable and convenient option for plumbing applications. They offer versatility, ease of installation, and the ability to adjust or reassemble connections if needed. However, proper installation techniques and considerations for compatibility with specific pipe materials are essential to ensure leak-free connections. It is important to evaluate the requirements of each plumbing project and consult with a plumbing professional for guidance on whether compression fittings are suitable for the specific application.