Introduction

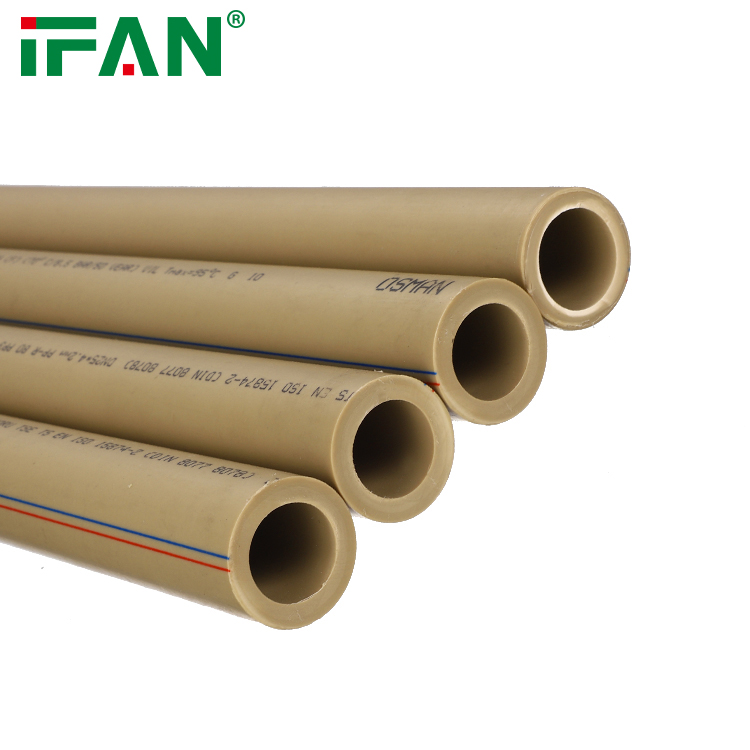

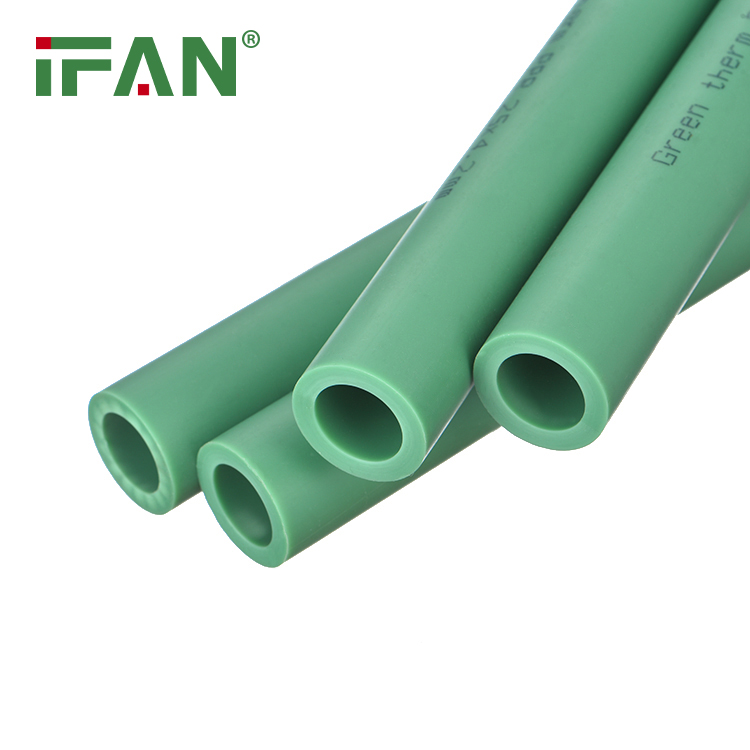

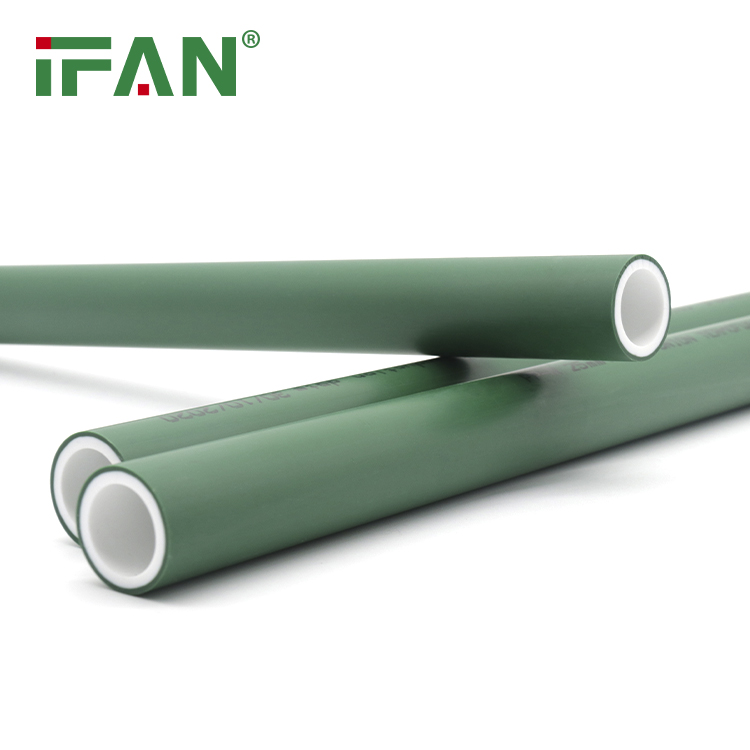

PPR pipe stands for Polypropylene Random Copolymer pipe. It is a type of plastic pipe that is widely used in plumbing systems for the transportation of potable water. PPR pipes are known for their durability, chemical resistance, and ability to withstand high temperatures. In this article, we will explore the meaning of PPR pipe and its composition in detail.

Definition of PPR pipe

PPR pipe is an acronym for Polypropylene Random Copolymer pipe. It is made from a thermoplastic polymer called polypropylene, which is a type of plastic known for its excellent chemical resistance and high-temperature resistance. The term “random copolymer” refers to the polymerization process in which two or more different monomers, in this case, propylene and a comonomer, are used to produce the pipe material.

Composition of PPR pipe

PPR pipes are composed of polypropylene, a versatile thermoplastic polymer. The composition of PPR pipe can vary depending on the specific requirements of the application, but the basic composition typically includes the following:

Polypropylene (PP) polymer

Polypropylene is the main component of PPR pipes. It is a semi-crystalline polymer that exhibits excellent chemical resistance, high-temperature resistance, and good mechanical properties. PP is derived from the polymerization of propylene monomers, which gives it its unique properties.

- Comonomer

In the production of PPR pipes, a comonomer is added to the propylene monomers during the polymerization process. The comonomer is typically an ethylene-based monomer, such as ethylene or butene. The addition of the comonomer helps improve the impact strength and flexibility of the PPR pipe.

- Stabilizers and Additives

Stabilizers and additives are often added to the PPR pipe composition to enhance its properties and performance. These include:

- Antioxidants: These additives help protect the PPR pipe from degradation caused by exposure to heat, light, and oxygen over time.

- UV stabilizers: UV stabilizers are added to PPR pipes to protect them from the harmful effects of ultraviolet (UV) radiation, which can cause degradation and discoloration.

- Lubricants: Lubricants are used to reduce friction during the extrusion process and improve the processability of the PPR pipe material.

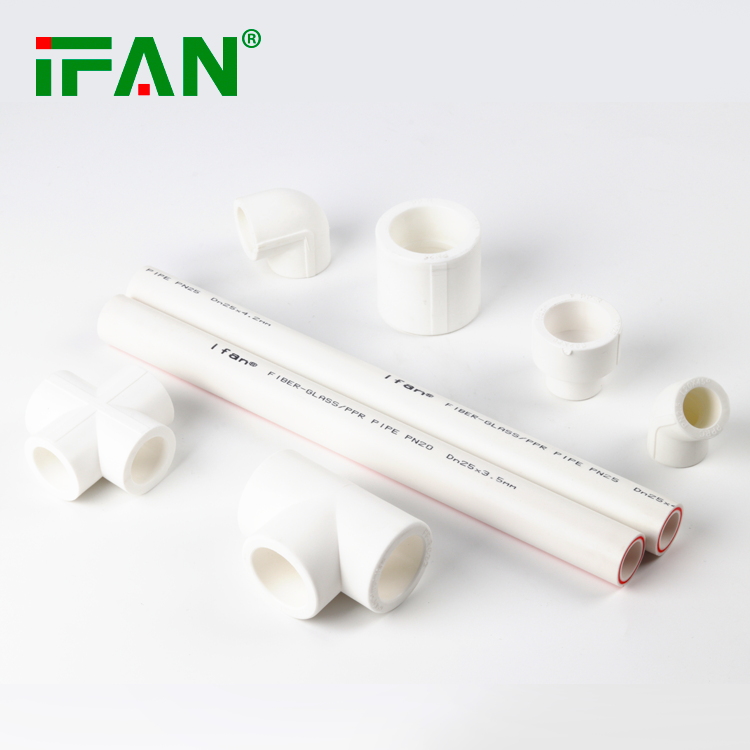

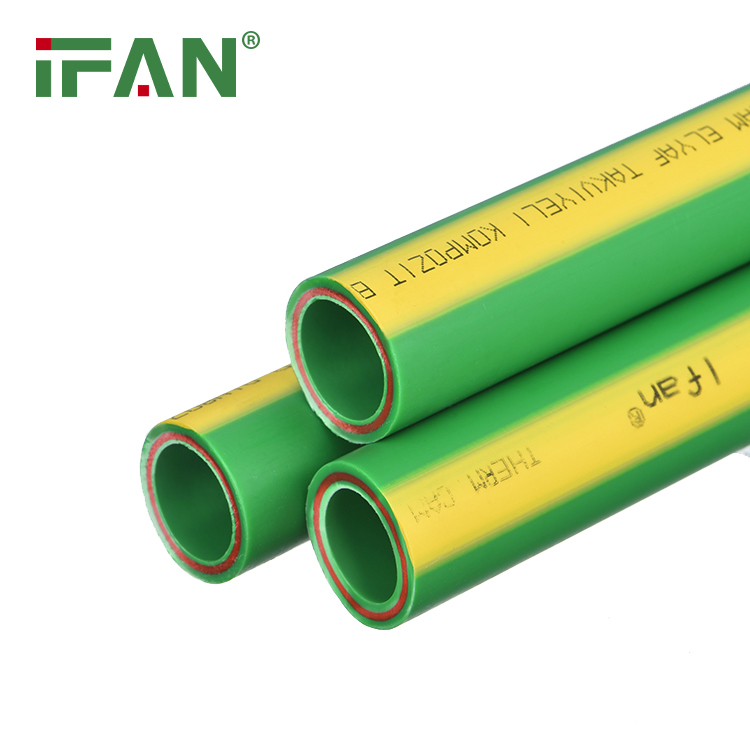

- Colorants: Colorants are added to PPR pipes to give them a specific color, allowing for easy identification and differentiation.

Advantages of PPR pipe

PPR pipes offer several advantages over other types of pipes commonly used in plumbing systems. Some of the key advantages of PPR pipes include:

- Chemical Resistance

PPR pipes exhibit excellent chemical resistance, making them suitable for the transportation of potable water. They are resistant to a wide range of chemicals, including acids, alkalis, and organic solvents, which ensures the purity and safety of the water being transported.

- High-Temperature Resistance

PPR pipes can withstand high temperatures, making them suitable for both hot and cold water supply systems. They can handle continuous operating temperatures of up to 70 degrees Celsius, enabling them to withstand hot water without deformation or degradation.

- Durability

PPR pipes are known for their durability. They have a long service life and are resistant to corrosion, scaling, and abrasion. This makes PPR pipes a reliable and cost-effective choice for plumbing systems, reducing the need for frequent maintenance and replacement.

- Easy Installation

PPR pipes are lightweight and flexible, making them easy to handle and install. They can be easily cut and joined using heat fusion methods, such as socket fusion or butt fusion, which ensures leak-free connections and reduces the risk of installation errors.

- Thermal Insulation Properties

PPR pipes have low thermal conductivity, which means they are excellent insulators. This helps reduce heat loss from the water inside the pipes, resulting in energy savings and improved efficiency in hot water supply systems.