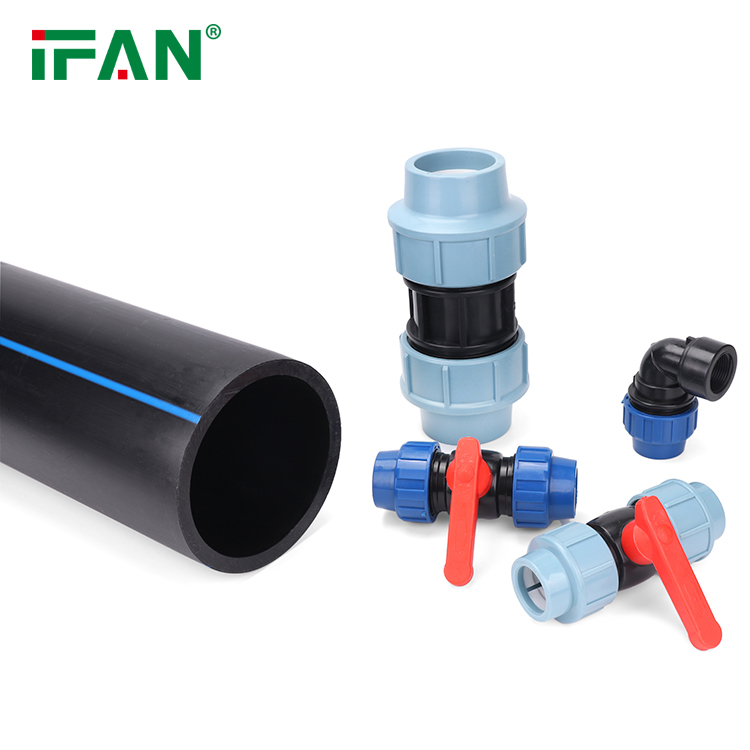

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

HDPE fittings are widely recognized for their durability, resistance to corrosion, and flexibility, making them an excellent choice for water and gas distribution systems. However, like any infrastructure component, proper maintenance and timely repair are essential to ensure the optimal performance of HDPE fittings. This article will guide you on how to maintain and repair HDPE fittings, ensuring they continue to function efficiently for many years.

Importance of Maintenance and Repair for HDPE Fittings

Proper maintenance and repair of HDPE fittings not only enhance their lifespan but also reduce the risk of costly repairs and system downtime. Routine inspections, timely repairs, and adherence to installation guidelines can prevent leaks, bursts, and other failures, ensuring that the water or gas distribution systems remain effective and efficient.

1. Regular Inspection of HDPE Fittings

Routine inspections are the first step in maintaining the integrity of HDPE fittings. These fittings are designed to last for decades, but environmental factors such as pressure changes, ground movement, and temperature fluctuations can still impact their condition.

How to Inspect HDPE Fittings:

- Visual Check: Look for any signs of visible damage like cracks, bulging, or scratches. These could indicate external stress or exposure to chemicals.

- Check for Leaks: Examine joints and connections to ensure they remain leak-free. Although HDPE fittings are typically joined through fusion (butt fusion or electrofusion), leaks can still occur if the joints were improperly fused.

- Inspect for Signs of Wear: Over time, HDPE fittings may experience wear and tear, especially in systems exposed to high pressure or external impacts.

Regular inspections can help you catch small issues before they escalate into larger problems.

2. Cleaning HDPE Fittings

Keeping your HDPE fittings clean is essential for maintaining their performance, especially in systems that handle chemicals, wastewater, or even potable water. Regular cleaning will prevent the buildup of debris or mineral deposits that could impede the flow of liquids or gases.

Cleaning Tips:

- Use Non-Abrasive Cleaning Tools: When cleaning HDPE fittings, avoid using abrasive materials that could scratch the surface and compromise their integrity.

- Flush with Water: Periodically flush the system with clean water to remove any accumulated particles. For systems dealing with chemicals, use a mild cleaning solution recommended for HDPE fittings.

- Inspect After Cleaning: After cleaning, inspect the fittings for any visible damage or changes in appearance.

Cleaning ensures that the HDPE fittings continue to operate without obstruction, especially in demanding environments like water treatment plants or industrial gas distribution systems.

3. Protecting HDPE Fittings from Environmental Factors

While HDPE fittings are designed to withstand harsh environments, taking extra precautions can further extend their life. UV rays, extreme temperatures, and exposure to harsh chemicals can degrade the material over time.

Protective Measures:

- UV Protection: If your HDPE fittings are installed in an outdoor environment, consider using UV-resistant coatings to protect them from sun damage. Extended exposure to UV rays can make the material brittle, causing cracks and failures.

- Temperature Control: HDPE fittings can handle a wide range of temperatures, but extreme heat or cold can cause them to become brittle or lose their flexibility. When possible, install insulation around the fittings to protect them from temperature extremes.

- Chemical Exposure: If your HDPE fittings are exposed to strong chemicals, consult the manufacturer’s guidelines to ensure they are compatible. Over time, some chemicals can weaken the material, leading to leaks or fractures.

By taking these preventive measures, you can prolong the life of your HDPE fittings and minimize the risk of damage due to environmental factors.

4. Repairing HDPE Fittings

Even with proper maintenance, there may be instances where HDPE fittings require repair due to physical damage, poor fusion, or accidental impact. Fortunately, HDPE fittings are relatively easy to repair, as long as the right techniques are employed.

Common Repair Methods:

- Butt Fusion Repair: Butt fusion is the most common method for repairing HDPE fittings. This involves using heat to fuse a new piece of HDPE pipe or fitting to the damaged area. Ensure that both surfaces to be fused are properly cleaned and aligned for a successful fusion.

- Electrofusion Repair: For smaller repairs, electrofusion fittings may be used. These fittings contain electrical elements that generate heat when an electric current is passed through them. This heat causes the HDPE material to melt and fuse together, creating a strong and leak-proof connection.

- Compression Fittings: In some cases, compression fittings can be used to quickly repair HDPE fittings. These are ideal for temporary repairs or when fusion methods are not feasible.

It is important to use proper tools and follow manufacturer guidelines during the repair process to ensure that the repair is successful and the fitting maintains its performance.

5. Preventing Damage to HDPE Fittings

Preventing damage is just as crucial as repairing it. While HDPE fittings are tough and resistant to many common issues, they are not impervious to all forms of damage. Taking the following steps can reduce the risk of damage to your HDPE fittings:

- Avoid Over-Pressurization: Excessive pressure can cause the fittings to rupture. Ensure that your system operates within the recommended pressure limits.

- Limit External Impact: During installation or maintenance, ensure that no heavy machinery or external forces are placed on the HDPE fittings, as this can cause cracks or distortions.

- Use Proper Installation Techniques: Incorrect installation, such as improper alignment or insufficient fusion, can lead to problems later on. Always follow the recommended installation procedures for HDPE fittings.

By taking these precautionary measures, you can significantly reduce the likelihood of needing major repairs.

6. Professional Assistance for Complex Repairs

While routine maintenance and simple repairs can be handled by operators, more complex issues might require professional help. If you encounter significant damage, such as extensive cracking, misalignment, or fusion issues that cannot be addressed with standard repair methods, it is best to call a professional.

Professionals can assess the damage and recommend the most suitable repair or replacement options, ensuring that the HDPE fittings are restored to their optimal performance.

Conclusion

HDPE fittings are a reliable and durable solution for water and gas distribution systems, but like any infrastructure component, they require proper maintenance and timely repairs to ensure long-term performance. Regular inspections, cleaning, protection from environmental factors, and proper repair techniques can significantly extend the life of HDPE fittings. By following these best practices, you can ensure that your system remains leak-free, efficient, and functional for many years to come.

Frequently Asked Questions (FAQ)

- How often should I inspect HDPE fittings?

- It’s recommended to inspect HDPE fittings at least once every six months to identify any potential issues such as leaks, cracks, or wear.

- Can I repair HDPE fittings myself?

- Yes, basic repairs such as butt fusion or electrofusion can often be done by trained personnel. However, more complex issues may require professional assistance.

- What is the lifespan of HDPE fittings?

- HDPE fittings typically have a lifespan of up to 50 years, depending on factors like the environment and proper maintenance.

- Can HDPE fittings handle high-pressure systems?

- Yes, HDPE fittings are designed to handle high-pressure environments, making them ideal for both water and gas distribution systems.

- How can I prevent UV damage to HDPE fittings?

- For outdoor installations, consider using UV-resistant coatings or wrapping the HDPE fittings with protective materials to shield them from prolonged UV exposure.

HDPE fittings are widely recognized for their durability, resistance to corrosion, and flexibility, making them an excellent choice for water and gas distribution systems. However, like any infrastructure component, proper maintenance and timely repair are essential to ensure the optimal performance of HDPE fittings. This article will guide you on how to maintain and repair HDPE fittings, ensuring they continue to function efficiently for many years.

Importance of Maintenance and Repair for HDPE Fittings

Proper maintenance and repair of HDPE fittings not only enhance their lifespan but also reduce the risk of costly repairs and system downtime. Routine inspections, timely repairs, and adherence to installation guidelines can prevent leaks, bursts, and other failures, ensuring that the water or gas distribution systems remain effective and efficient.

1. Regular Inspection of HDPE Fittings

Routine inspections are the first step in maintaining the integrity of HDPE fittings. These fittings are designed to last for decades, but environmental factors such as pressure changes, ground movement, and temperature fluctuations can still impact their condition.

How to Inspect HDPE Fittings:

- Visual Check: Look for any signs of visible damage like cracks, bulging, or scratches. These could indicate external stress or exposure to chemicals.

- Check for Leaks: Examine joints and connections to ensure they remain leak-free. Although HDPE fittings are typically joined through fusion (butt fusion or electrofusion), leaks can still occur if the joints were improperly fused.

- Inspect for Signs of Wear: Over time, HDPE fittings may experience wear and tear, especially in systems exposed to high pressure or external impacts.

Regular inspections can help you catch small issues before they escalate into larger problems.

2. Cleaning HDPE Fittings

Keeping your HDPE fittings clean is essential for maintaining their performance, especially in systems that handle chemicals, wastewater, or even potable water. Regular cleaning will prevent the buildup of debris or mineral deposits that could impede the flow of liquids or gases.

Cleaning Tips:

- Use Non-Abrasive Cleaning Tools: When cleaning HDPE fittings, avoid using abrasive materials that could scratch the surface and compromise their integrity.

- Flush with Water: Periodically flush the system with clean water to remove any accumulated particles. For systems dealing with chemicals, use a mild cleaning solution recommended for HDPE fittings.

- Inspect After Cleaning: After cleaning, inspect the fittings for any visible damage or changes in appearance.

Cleaning ensures that the HDPE fittings continue to operate without obstruction, especially in demanding environments like water treatment plants or industrial gas distribution systems.

3. Protecting HDPE Fittings from Environmental Factors

While HDPE fittings are designed to withstand harsh environments, taking extra precautions can further extend their life. UV rays, extreme temperatures, and exposure to harsh chemicals can degrade the material over time.

Protective Measures:

- UV Protection: If your HDPE fittings are installed in an outdoor environment, consider using UV-resistant coatings to protect them from sun damage. Extended exposure to UV rays can make the material brittle, causing cracks and failures.

- Temperature Control: HDPE fittings can handle a wide range of temperatures, but extreme heat or cold can cause them to become brittle or lose their flexibility. When possible, install insulation around the fittings to protect them from temperature extremes.

- Chemical Exposure: If your HDPE fittings are exposed to strong chemicals, consult the manufacturer’s guidelines to ensure they are compatible. Over time, some chemicals can weaken the material, leading to leaks or fractures.

By taking these preventive measures, you can prolong the life of your HDPE fittings and minimize the risk of damage due to environmental factors.

4. Repairing HDPE Fittings

Even with proper maintenance, there may be instances where HDPE fittings require repair due to physical damage, poor fusion, or accidental impact. Fortunately, HDPE fittings are relatively easy to repair, as long as the right techniques are employed.

Common Repair Methods:

- Butt Fusion Repair: Butt fusion is the most common method for repairing HDPE fittings. This involves using heat to fuse a new piece of HDPE pipe or fitting to the damaged area. Ensure that both surfaces to be fused are properly cleaned and aligned for a successful fusion.

- Electrofusion Repair: For smaller repairs, electrofusion fittings may be used. These fittings contain electrical elements that generate heat when an electric current is passed through them. This heat causes the HDPE material to melt and fuse together, creating a strong and leak-proof connection.

- Compression Fittings: In some cases, compression fittings can be used to quickly repair HDPE fittings. These are ideal for temporary repairs or when fusion methods are not feasible.

It is important to use proper tools and follow manufacturer guidelines during the repair process to ensure that the repair is successful and the fitting maintains its performance.

5. Preventing Damage to HDPE Fittings

Preventing damage is just as crucial as repairing it. While HDPE fittings are tough and resistant to many common issues, they are not impervious to all forms of damage. Taking the following steps can reduce the risk of damage to your HDPE fittings:

- Avoid Over-Pressurization: Excessive pressure can cause the fittings to rupture. Ensure that your system operates within the recommended pressure limits.

- Limit External Impact: During installation or maintenance, ensure that no heavy machinery or external forces are placed on the HDPE fittings, as this can cause cracks or distortions.

- Use Proper Installation Techniques: Incorrect installation, such as improper alignment or insufficient fusion, can lead to problems later on. Always follow the recommended installation procedures for HDPE fittings.

By taking these precautionary measures, you can significantly reduce the likelihood of needing major repairs.

6. Professional Assistance for Complex Repairs

While routine maintenance and simple repairs can be handled by operators, more complex issues might require professional help. If you encounter significant damage, such as extensive cracking, misalignment, or fusion issues that cannot be addressed with standard repair methods, it is best to call a professional.

Professionals can assess the damage and recommend the most suitable repair or replacement options, ensuring that the HDPE fittings are restored to their optimal performance.

Conclusion

HDPE fittings are a reliable and durable solution for water and gas distribution systems, but like any infrastructure component, they require proper maintenance and timely repairs to ensure long-term performance. Regular inspections, cleaning, protection from environmental factors, and proper repair techniques can significantly extend the life of HDPE fittings. By following these best practices, you can ensure that your system remains leak-free, efficient, and functional for many years to come.

Frequently Asked Questions (FAQ)

- How often should I inspect HDPE fittings?

- It’s recommended to inspect HDPE fittings at least once every six months to identify any potential issues such as leaks, cracks, or wear.

- Can I repair HDPE fittings myself?

- Yes, basic repairs such as butt fusion or electrofusion can often be done by trained personnel. However, more complex issues may require professional assistance.

- What is the lifespan of HDPE fittings?

- HDPE fittings typically have a lifespan of up to 50 years, depending on factors like the environment and proper maintenance.

- Can HDPE fittings handle high-pressure systems?

- Yes, HDPE fittings are designed to handle high-pressure environments, making them ideal for both water and gas distribution systems.

- How can I prevent UV damage to HDPE fittings?

- For outdoor installations, consider using UV-resistant coatings or wrapping the HDPE fittings with protective materials to shield them from prolonged UV exposure.