IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

In the world of modern infrastructure, the importance of reliable, durable, and efficient piping systems cannot be overstated. HDPE fittings, or High-Density Polyethylene fittings, have rapidly gained popularity for both water and gas distribution systems due to their impressive performance and cost-effectiveness. These fittings are essential components used in plumbing and piping systems, offering a host of advantages that make them a preferred choice in many industries. In this article, we’ll explore why HDPE fittings are the future of water and gas distribution, highlighting their benefits, uses, and why they outperform traditional materials.

What are HDPE Fittings?

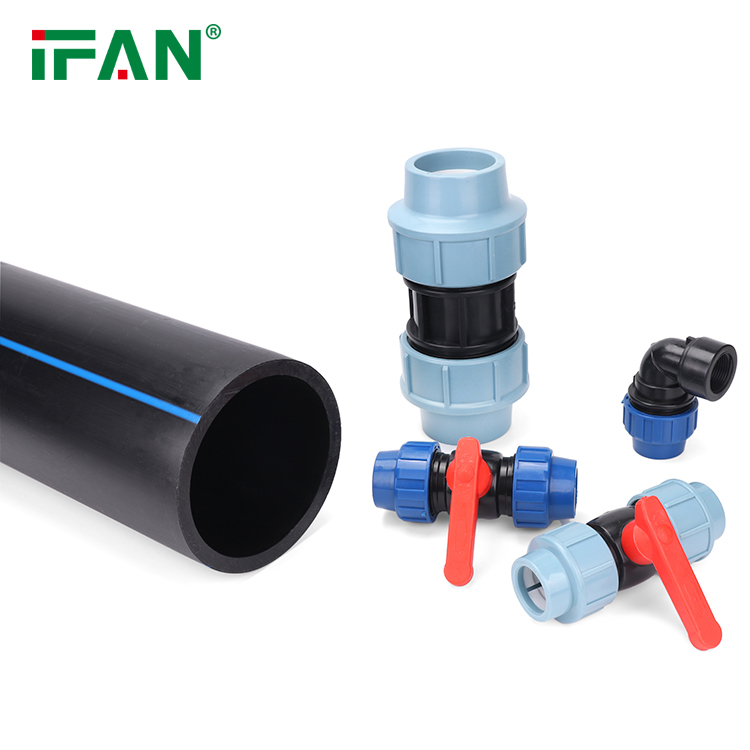

HDPE fittings are made from high-density polyethylene, a thermoplastic polymer known for its exceptional strength, flexibility, and resistance to chemicals and environmental factors. These fittings are designed to connect, redirect, or control the flow of liquids and gases within a piping system. HDPE is a preferred material for water and gas distribution due to its high resistance to corrosion, ease of installation, and long-lasting durability.

Key Features of HDPE Fittings:

- Corrosion Resistance: Unlike metal pipes, HDPE fittings are highly resistant to rust and corrosion, making them ideal for systems that are exposed to water or harsh chemicals.

- Flexibility and Durability: HDPE is a flexible material that can withstand physical stresses, making it less prone to cracking or breaking under pressure.

- Leak-Free Joints: HDPE fittings can be fused together using butt fusion or electrofusion, ensuring that joints are leak-free and capable of withstanding high-pressure environments.

- Long Lifespan: HDPE fittings can last up to 50 years or more, offering a low-maintenance and long-term solution for piping systems.

Why Are HDPE Fittings the Future of Water and Gas Distribution?

1. Cost-Effectiveness

One of the primary reasons HDPE fittings are becoming increasingly popular is their cost-effectiveness. The material itself is less expensive than metals like steel or copper, and the installation process is generally more affordable as well. Traditional piping materials often require specialized tools and labor-intensive techniques, driving up both material and installation costs. HDPE fittings, on the other hand, are easier to handle, reducing labor costs and installation time.

Additionally, the durability of HDPE fittings means lower maintenance costs over time. Unlike steel or cast iron pipes, which are prone to rust, HDPE fittings remain unaffected by corrosion, meaning fewer repairs and replacements are needed throughout their lifespan.

2. Corrosion and Chemical Resistance

HDPE fittings have superior resistance to a wide range of chemicals, including acids, alkalis, and salts. This makes them ideal for both water and gas distribution systems in various industrial sectors, such as agriculture, chemical plants, and municipal water treatment facilities.

Traditional piping materials like copper, steel, and iron are often prone to rust and corrosion when exposed to water and chemicals over time. In contrast, HDPE fittings maintain their integrity and reliability in even the harshest conditions, ensuring a long-lasting and safe water or gas distribution system.

3. Leak-Free Connections

HDPE fittings offer a reliable and secure method for joining pipes, making them virtually leak-proof. The fusion process used to connect HDPE fittings creates seamless joints, eliminating the possibility of leaks that are common in threaded, soldered, or bolted pipe joints. This is particularly important in gas distribution systems, where even a small leak can lead to dangerous situations.

For water distribution, leak-free connections are crucial for preventing water loss and minimizing maintenance costs. The long-lasting, leak-proof nature of HDPE fittings contributes to the overall efficiency and sustainability of water distribution systems.

4. Flexibility for Installation

The flexibility of HDPE fittings makes them easier to install in a variety of environments. Unlike rigid pipes made from materials like PVC or copper, HDPE fittings can be bent and maneuvered to fit tight or difficult spaces without the need for excessive fittings or joints. This flexibility also makes them an ideal choice for underground installations, as they can be pulled through trenches and curves without the need for additional fittings.

Moreover, HDPE fittings are resistant to cracking or breaking under pressure, ensuring that they will maintain their structural integrity even in challenging environments such as fluctuating temperatures or ground shifts.

5. Environmental Benefits

The environmental benefits of HDPE fittings are another reason they are becoming the future of water and gas distribution systems. HDPE is a recyclable material, and many manufacturers focus on using recycled HDPE in their products, which reduces waste and promotes sustainability. Furthermore, HDPE fittings are more energy-efficient to produce compared to traditional materials like metal, which require high temperatures and energy-intensive processes for production.

With increasing concerns over the environmental impact of construction materials, HDPE fittings provide a more sustainable alternative without compromising on performance.

6. Resistance to Freezing and Impact

In cold climates, HDPE fittings are particularly advantageous due to their ability to expand and contract without breaking. When exposed to freezing temperatures, HDPE pipes and fittings can expand to accommodate the ice, reducing the risk of cracks or bursts that often occur with more rigid materials like copper or PVC.

Additionally, HDPE fittings are highly resistant to impact damage. This makes them less prone to cracking or breaking due to physical stress, such as ground movement, external pressure, or accidental impacts during installation or maintenance.

7. Long-Term Performance

The durability of HDPE fittings is one of their most significant advantages. With a lifespan of up to 50 years or more, HDPE fittings require minimal maintenance, reducing long-term costs for water and gas distribution systems. This longevity is particularly beneficial for municipalities and large-scale industrial applications, where long-term reliability is crucial for maintaining smooth operations.

8. Versatility in Applications

HDPE fittings are versatile and can be used in various applications, including water distribution, gas distribution, wastewater treatment, and irrigation systems. Their ability to handle different fluids and gases makes them an excellent choice for many industries, including agriculture, construction, and municipal waterworks.

Conclusion

HDPE fittings offer a combination of durability, flexibility, and cost-effectiveness that make them the future of water and gas distribution systems. With their resistance to corrosion, ease of installation, and long-lasting performance, HDPE fittings provide a reliable and sustainable alternative to traditional materials. As infrastructure demands grow and the need for efficient and environmentally-friendly systems becomes more critical, HDPE fittings are positioned to play a key role in the development of modern water and gas distribution systems worldwide.

Frequently Asked Questions (FAQ)

- What is the difference between HDPE fittings and PVC fittings? HDPE fittings are more flexible and durable than PVC fittings. HDPE fittings are resistant to cracking and can handle higher pressure, making them ideal for both water and gas distribution systems. PVC fittings, while cost-effective, are more rigid and prone to damage from physical stress.

- How long do HDPE fittings last? HDPE fittings have a lifespan of up to 50 years or more, depending on the environment and how well they are maintained.

- Can HDPE fittings be used for both water and gas distribution? Yes, HDPE fittings are versatile and can be used in both water and gas distribution systems, providing a safe, reliable, and cost-effective solution for various industries.

- Are HDPE fittings resistant to corrosion? Yes, HDPE fittings are highly resistant to corrosion and are ideal for environments exposed to water or chemicals, unlike metal pipes which can rust over time.

- Can HDPE fittings handle freezing temperatures? Yes, HDPE fittings are resistant to freezing and can expand without breaking, making them a great choice for installations in cold climates.