In recent years, PEX (cross-linked polyethylene) plumbing pipes have gained immense popularity among homeowners and contractors alike. Known for their flexibility, durability, and ease of installation, PEX pipes are revolutionizing plumbing systems. This comprehensive guide will cover everything you need to know about PEX plumbing pipes, including their benefits, installation processes, types, and maintenance tips.

1. What is PEX?

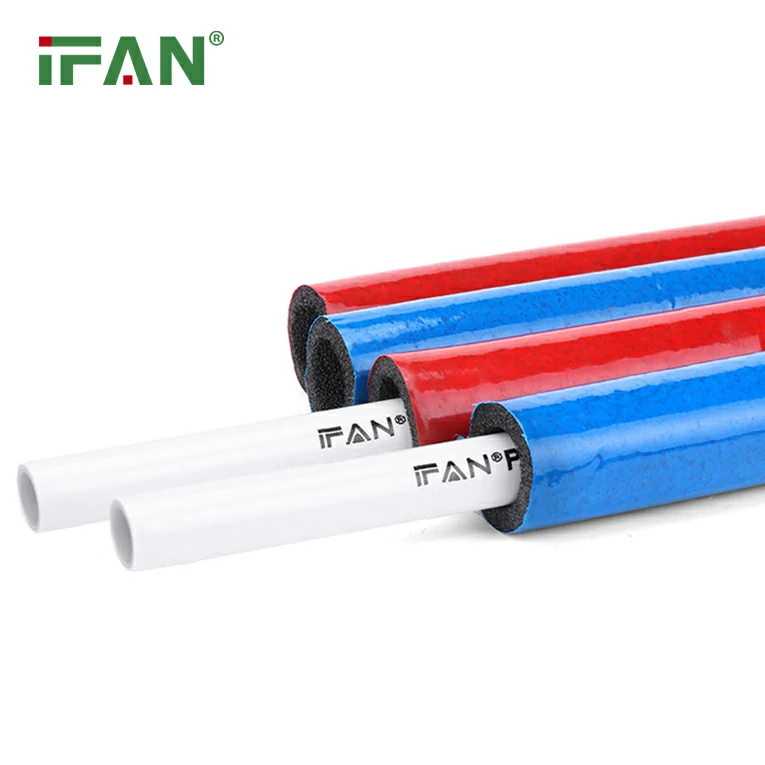

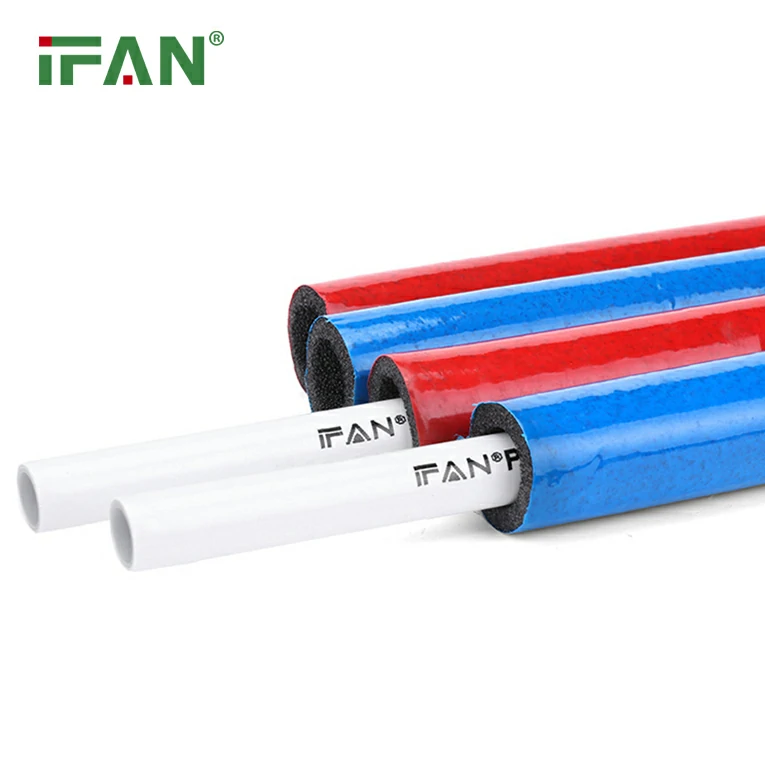

PEX stands for cross-linked polyethylene, a type of plastic piping that is commonly used in plumbing systems. The cross-linking process enhances the material’s strength and resistance to temperature changes, making it suitable for both hot and cold water applications. PEX is available in various colors, typically red for hot water and blue for cold water, allowing for easy identification during installation.

2. Advantages of PEX Plumbing Pipes

2.1. Flexibility

One of the most significant advantages of PEX is its flexibility. Unlike rigid piping materials, PEX can be bent and curved, allowing for easier installation in tight spaces. This flexibility reduces the need for fittings and joints, which can be potential leak points.

2.2. Resistance to Corrosion

PEX pipes are resistant to corrosion and scale buildup, which can be common issues with metal pipes. This property extends the lifespan of the plumbing system and helps maintain water quality.

2.3. Thermal Insulation

PEX has excellent thermal insulation properties, which helps maintain the temperature of the water flowing through the pipes. This characteristic reduces heat loss, making it more energy-efficient compared to traditional piping materials.

2.4. Lower Installation Costs

The lightweight nature of PEX makes it easier to handle and transport, leading to lower labor costs during installation. Additionally, the flexibility of PEX reduces the need for fittings, further cutting down on expenses.

2.5. Freeze Resistance

In colder climates, PEX pipes are less likely to burst due to freezing. The material can expand slightly when water freezes, reducing the risk of damage compared to rigid pipes.

3. Types of PEX Pipes

There are three main types of PEX pipes, each with specific applications:

3.1. PEX-A

PEX-A is produced using the Engel method, which creates a highly flexible and durable pipe. This type of PEX has the highest resistance to kinking and is often used in applications requiring bending or curving.

3.2. PEX-B

PEX-B is manufactured using the Silane method, resulting in a slightly less flexible pipe than PEX-A. However, it is still highly durable and is commonly used for residential plumbing systems.

3.3. PEX-C

PEX-C is produced using a different cross-linking process, which makes it the least flexible of the three types. It is often used in commercial applications and is suitable for straight runs.

4. Installation of PEX Plumbing Pipes

4.1. Tools Required

To install PEX plumbing pipes, you will need the following tools:

- PEX cutter

- Crimping tool or clamp tool

- Measuring tape

- Marker

- Pipe supports

4.2. Step-by-Step Installation Process

- Planning the Layout: Before installation, plan the layout of your plumbing system. Consider the locations of fixtures, appliances, and any potential obstacles.

- Cutting the PEX: Use a PEX cutter to cut the pipe to the desired length. Ensure the cut is straight for a secure connection.

- Attaching Fittings: Slide a crimp ring onto the end of the PEX pipe, then insert the fitting. Use the crimping tool to secure the ring in place.

- Securing the Pipes: Use pipe supports to secure the PEX pipes to walls or ceilings. This helps prevent sagging and ensures proper water flow.

- Testing the System: Once the installation is complete, turn on the water supply and check for leaks. If any leaks are detected, tighten the fittings as necessary.

5. Maintenance Tips for PEX Plumbing Pipes

5.1. Regular Inspections

Conduct regular inspections of your plumbing system to identify any signs of wear or damage. Look for leaks, discoloration, or unusual noises.

5.2. Avoiding UV Exposure

PEX pipes should not be exposed to direct sunlight for extended periods, as UV rays can degrade the material. If outdoor installation is necessary, ensure the pipes are properly insulated or covered.

5.3. Temperature Considerations

While PEX is resistant to freezing, it’s essential to maintain a consistent temperature in areas where pipes are exposed to extreme cold. Insulate pipes in unheated spaces, such as attics or crawl spaces.

5.4. Be Cautious with Chemicals

Avoid exposing PEX pipes to harsh chemicals, solvents, or petroleum-based products, as these