In the ever-evolving plumbing industry, the demand for high-quality, durable, and efficient piping systems has never been greater. KPT Pipes has emerged as a frontrunner in the manufacturing of PPR (Polypropylene Random Copolymer) pipes and fittings, setting new standards in quality, innovation, and sustainability. This article delves into the features and benefits of PPR fittings, the manufacturing processes at KPT Pipes, and the various applications of these products in residential, commercial, and industrial settings.

1. Understanding PPR Fittings

1.1. What Are PPR Fittings?

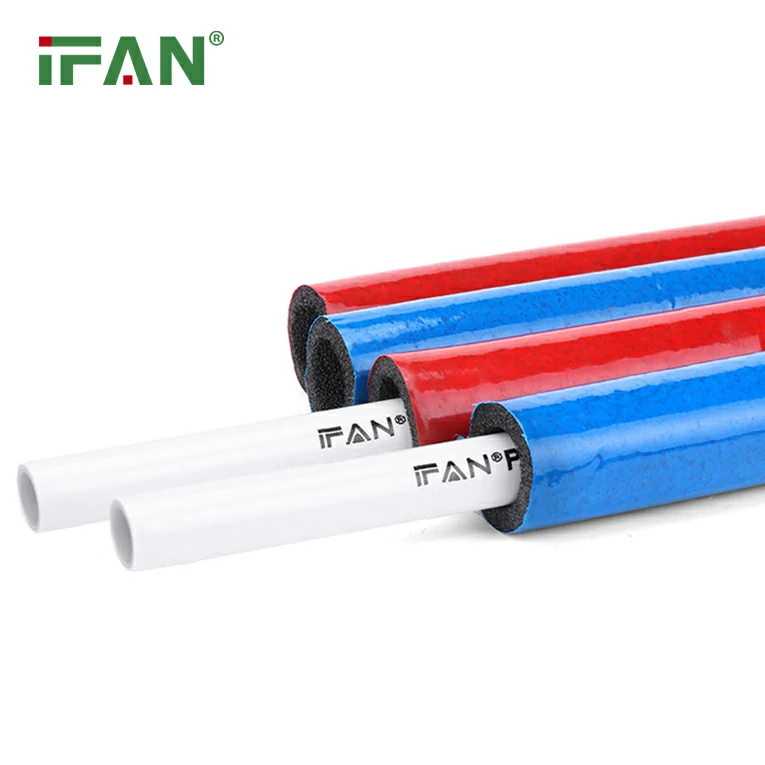

PPR fittings are essential components in plumbing systems, made from a robust thermoplastic material known for its excellent physical and chemical properties. These fittings are designed to connect pipes securely, ensuring a leak-free and efficient flow of water. PPR fittings are lightweight, easy to install, and resistant to corrosion, making them an ideal choice for modern plumbing applications.

1.2. Types of PPR Fittings

PPR fittings come in various shapes and sizes to accommodate different plumbing needs. Some common types include:

- Elbows: Used to change the direction of the piping system.

- Tees: Allow for branching off into different directions.

- Couplings: Connect two sections of pipe together.

- Female and Male Socket Fittings: Used for joining pipes of different diameters or for connecting to other fittings.

2. The Advantages of PPR Fittings

2.1. Durability and Longevity

One of the most significant advantages of PPR fittings is their durability. They can withstand high pressure and temperature, making them suitable for both hot and cold water applications. PPR fittings have a long lifespan, often exceeding 50 years with proper installation and maintenance.

2.2. Corrosion Resistance

Unlike metal fittings, PPR fittings are resistant to corrosion. This characteristic ensures that the fittings maintain their structural integrity and performance over time, even in challenging environments where exposure to chemicals is common.

2.3. Lightweight and Easy to Install

PPR fittings are significantly lighter than traditional metal fittings, making them easier to handle and install. Their lightweight nature reduces transportation costs and labor requirements during installation.

2.4. Cost-Effectiveness

PPR fittings offer a cost-effective solution for plumbing systems. Their durability and low maintenance requirements lead to long-term savings, making them an economical choice for both residential and commercial applications.

3. KPT Pipes: Leading the Way in PPR Manufacturing

3.1. Commitment to Quality

KPT Pipes prioritizes quality in every aspect of its manufacturing process. The company employs advanced technology and rigorous testing standards to ensure that its PPR pipes and fittings meet international quality benchmarks. This commitment to quality translates into products that are reliable and durable, providing customers with peace of mind.

3.2. Sustainable Manufacturing Practices

Sustainability is at the core of KPT Pipes’ operations. The company employs eco-friendly practices in its manufacturing processes, minimizing waste and reducing its carbon footprint. By using recyclable materials and energy-efficient technologies, KPT Pipes is leading the way in environmentally responsible manufacturing.

3.3. Innovative Product Range

KPT Pipes offers a diverse range of PPR pipes and fittings designed to meet various plumbing needs. Their product line includes:

- PPR Pipes: Available in different diameters and pressure ratings for various applications.

- PPR Fittings: A comprehensive range of fittings, including elbows, tees, and couplings, designed for seamless integration with PPR pipes.

4. Applications of PPR Fittings

4.1. Residential Plumbing

In residential settings, PPR fittings are widely used for water supply systems, heating systems, and irrigation. Their durability and resistance to temperature fluctuations make them ideal for domestic use.

4.2. Commercial Buildings

PPR fittings are increasingly being used in commercial buildings for efficient water distribution. Their lightweight nature and ease of installation allow for quick and cost-effective plumbing solutions.

4.3. Industrial Applications

In industrial environments, PPR fittings are used for transporting chemicals and other fluids. Their resistance to corrosion and chemicals makes them suitable for various industrial applications, ensuring safety and reliability.

5. Installation of PPR Fittings

5.1. Preparation

Before installation, ensure that you have all necessary tools and materials, including:

- PPR pipes and fittings

- Pipe cutter

- Heat fusion tool

- Measuring tape

- Marker

5.2. Steps for Installation

- Measure and Cut: Measure the required length of the PPR pipe and cut it using a pipe cutter to ensure a clean, straight edge.

- Prepare the Fittings: Clean the ends of the PPR pipe and the interior of the fitting to remove any