IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

In modern plumbing systems, ensuring leak-free connections is a top priority for both professionals and DIY enthusiasts. Polypropylene Random Copolymer (PPR) fittings have gained widespread popularity due to their reliability, durability, and ability to create secure, leak-free plumbing systems. This article will explore how PPR fittings work, why they are effective at preventing leaks, and the installation practices that can guarantee optimal performance.

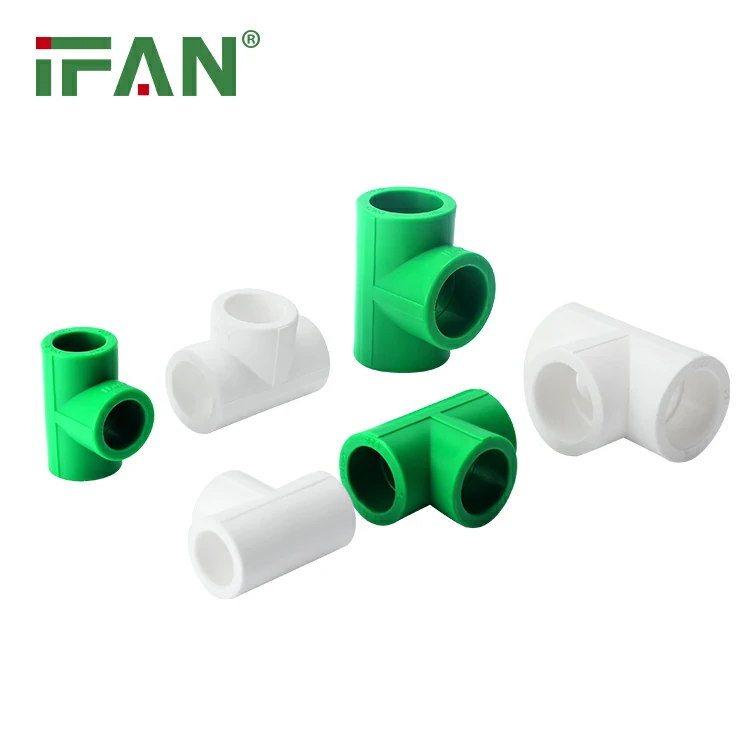

What Are PPR Fittings?

PPR fittings are plumbing components made from polypropylene, a thermoplastic polymer known for its excellent resistance to heat, pressure, and corrosion. These fittings are designed to connect PPR pipes, which are often used for both hot and cold water systems. The key to their popularity lies in their ability to form a secure, leak-resistant bond when installed correctly.

Why Are Leak-Free Connections Important?

Leak-free connections are crucial in plumbing systems for several reasons:

- Prevent Water Damage: Even a small leak can lead to significant water damage over time, compromising the integrity of walls, floors, and ceilings.

- Maintain System Efficiency: Leaks waste water, which increases utility costs and reduces the efficiency of the plumbing system.

- Ensure Long-Term Durability: Leaks, if not addressed, can lead to corrosion, mold growth, and other issues that shorten the lifespan of the plumbing system.

To achieve leak-free performance, it’s important to understand the properties of PPR fittings and the installation techniques that ensure their effectiveness.

How Do PPR Fittings Prevent Leaks?

PPR fittings create leak-free plumbing systems through a combination of their material properties and the heat fusion process used during installation. Here’s a breakdown of the factors that contribute to their leak-proof nature:

1. Heat Fusion Technology

Unlike traditional plumbing methods that rely on mechanical connections (such as threaded or glued joints), PPR fittings are installed using a heat fusion process. The process involves heating both the pipe and the fitting until they become soft and pliable. Once heated, the PPR pipe is inserted into the fitting, and both components fuse together, forming a single, seamless joint.

This fusion creates a molecular bond that is as strong as the material itself, ensuring that there are no gaps or weak points where leaks could occur. The result is a perfectly sealed connection that resists both pressure and temperature changes.

2. Uniform Material Distribution

One of the key advantages of PPR fittings is that the material is homogeneous throughout the fitting. Unlike metal pipes or fittings, which may have seams or joints that can weaken over time, PPR fittings are made from a single, uniform material. This consistency in the material ensures that there are no weak spots where water might escape.

Moreover, the fusion process eliminates any potential for gaps between the pipe and the fitting, as the molten plastic completely fills the space during installation.

3. Resistance to Corrosion and Chemical Damage

PPR fittings are highly resistant to corrosion and chemical damage, which are two primary causes of leaks in traditional plumbing systems. Metal pipes and fittings, such as those made of copper or steel, are prone to rust and corrosion when exposed to water and air over time. As these materials degrade, they can develop holes or cracks where water can escape.

In contrast, PPR fittings are impervious to corrosion. The polypropylene material used in these fittings does not react with water, even when exposed to high levels of minerals or chemicals. This resistance to corrosion ensures that the plumbing system remains intact and leak-free for decades.

4. Ability to Withstand High Pressure

PPR fittings are designed to handle high water pressure without compromising the integrity of the connection. The heat fusion process ensures that the joint between the pipe and the fitting can withstand substantial pressure without loosening or developing leaks. This makes PPR fittings ideal for both residential and commercial plumbing systems, where fluctuating water pressure can cause issues for other types of fittings.

5. Temperature Resistance

Another key feature of PPR fittings is their ability to resist high temperatures. They are rated for use in both hot and cold water systems, withstanding temperatures ranging from -10°C to 95°C (14°F to 203°F). This wide temperature tolerance ensures that the fittings remain leak-free even when exposed to extreme hot water or freezing conditions, which can cause other materials to crack or expand, leading to leaks.

Proper Installation for Leak-Free Results

While PPR fittings have many benefits, ensuring a leak-free plumbing system also depends on the correct installation process. Here are some best practices for installing PPR fittings to achieve the best results:

1. Use the Right Tools

To install PPR fittings correctly, you need specialized tools, including a pipe cutter, heating tool, and deburring tool. The pipe cutter should be sharp enough to ensure a clean, straight cut, as any rough edges can cause leaks. The heating tool is essential for softening the pipe and fitting so they can be fused together securely.

2. Ensure Proper Heating and Fusion

The key to creating a leak-proof joint is to heat the PPR pipe and the fitting to the correct temperature. The heating tool should evenly heat both components without overheating, which could damage the material. Once heated, insert the pipe into the fitting quickly and hold them together for a few seconds to allow the bond to form. Ensure that the pipe is fully inserted into the fitting to create a solid, seamless connection.

3. Allow for Cooling and Solidification

After the pipe and fitting are fused, allow them to cool for several minutes. During this time, the material will solidify and form a strong, leak-proof joint. Avoid applying pressure or disturbing the joint while it cools, as this could weaken the bond.

4. Test for Leaks

After installation, it’s important to test the system for leaks. Run water through the pipes and check all the joints carefully for signs of leakage. If any leaks are detected, they should be addressed immediately, as even a small leak can lead to bigger issues down the road.

Why Choose PPR Fittings for Leak-Free Plumbing?

There are several reasons why PPR fittings are an excellent choice for creating leak-free plumbing systems:

- Durability: PPR fittings can last for decades without deteriorating, ensuring a long-lasting, leak-free system.

- Corrosion Resistance: Unlike metal fittings, PPR fittings will not corrode over time, reducing the likelihood of leaks caused by material degradation.

- Ease of Installation: The heat fusion process makes installing PPR fittings quick and straightforward, even for those with limited plumbing experience.

- Cost-Effectiveness: PPR fittings are affordable and offer long-term savings by preventing leaks and reducing the need for maintenance and repairs.

Common FAQs About PPR Fittings and Leak Prevention

1. What are the main advantages of PPR fittings?

PPR fittings offer several advantages, including durability, corrosion resistance, ease of installation, and resistance to high temperatures and pressure, all of which contribute to a leak-free plumbing system.

2. Can PPR fittings be used for both hot and cold water?

Yes, PPR fittings are ideal for both hot and cold water systems due to their high temperature resistance.

3. Do PPR fittings require special tools for installation?

Yes, PPR fittings require specialized tools like a pipe cutter, heating tool, and deburring tool to ensure a secure, leak-free connection.

4. How long do PPR fittings last?

When installed properly, PPR fittings can last for decades without showing signs of wear or deterioration.

5. Can I install PPR fittings myself?

Yes, PPR fittings are relatively easy to install with the right tools and techniques. However, it is important to follow the proper steps for heating and fusing the fittings to ensure leak-free performance.

By understanding how PPR fittings work and following the correct installation practices, you can ensure a plumbing system that is not only reliable but also resistant to leaks for years to come.