Introduction

In the world of plumbing and construction, the importance of reliable and durable piping systems cannot be overstated. Polypropylene Random Copolymer (PPR) pipes have emerged as a popular choice for various applications due to their numerous benefits, including corrosion resistance, lightweight nature, and ease of installation. However, even the best materials can face challenges over time. In this article, we will explore the current state of Ti’s PPR-pipe trestle, examining the issues it faces, the implications of these challenges, and potential solutions to restore its functionality.

Understanding PPR Pipes

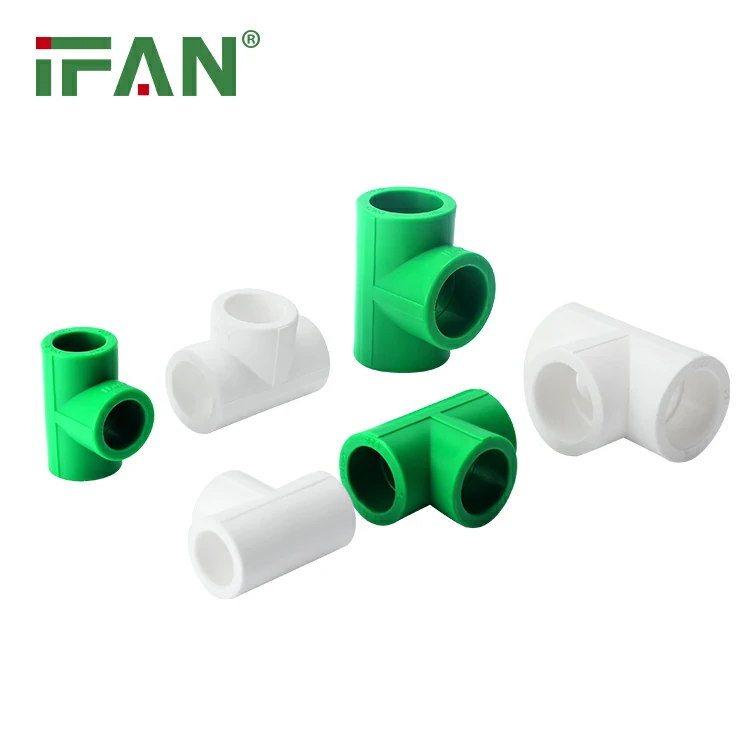

What Are PPR Pipes?

PPR pipes are made from a thermoplastic polymer known as Polypropylene Random Copolymer. These pipes are widely used in plumbing systems for both residential and commercial applications, including water supply, heating systems, and irrigation. Their popularity stems from their durability, resistance to corrosion, and low maintenance requirements.

Key Features of PPR Pipes

- Corrosion Resistance: Unlike metal pipes, PPR pipes do not rust or corrode, ensuring that the water transported remains clean and safe for consumption.

- High Temperature and Pressure Tolerance: PPR pipes can withstand high temperatures (up to 95°C or 203°F) and pressures (up to 20 bars or approximately 290 psi), making them suitable for various applications.

- Lightweight and Easy to Install: PPR pipes are lightweight, which simplifies transportation and installation processes, reducing labor costs.

- Low Maintenance Needs: Due to their resistance to scaling and deposits, PPR pipes require minimal maintenance, leading to long-term savings for users.

- Eco-Friendly: PPR pipes are recyclable, contributing to sustainable practices within the plumbing and construction industries.

The Current State of Ti’s PPR-Pipe Trestle

Overview of the Trestle

Ti’s PPR-pipe trestle is a critical component of the local plumbing infrastructure, designed to support a network of PPR pipes that transport water to various facilities and homes. However, recent inspections have revealed that the trestle is in bad shape, raising concerns about its structural integrity and the potential for water loss or contamination.

Identifying the Issues

- Structural Damage: The trestle has shown signs of wear and tear, including cracks and instability in its support structures. This damage can compromise the entire piping system, leading to leaks and inefficiencies.

- Corrosion of Support Materials: While PPR pipes themselves are resistant to corrosion, the materials used to support the trestle may not be. If these materials corrode, they can weaken the structure and lead to further issues.

- Improper Installation: In some cases, the trestle may have been improperly installed, leading to uneven weight distribution and increased stress on certain sections. This can exacerbate existing issues and shorten the lifespan of the system.

- Environmental Factors: Exposure to harsh weather conditions, including heavy rainfall, flooding, and extreme temperatures, can impact the integrity of the trestle and the PPR pipes it supports.

Implications of a Damaged Trestle

The current condition of Ti’s PPR-pipe trestle has several implications for the local water supply system:

- Increased Water Loss: Structural damage can lead to leaks in the piping system, resulting in significant water loss. This not only wastes a valuable resource but also increases operational costs for water authorities.

- Potential Contamination: If the trestle fails, it could lead to contamination of the water supply, posing health risks to residents and businesses that rely on the system for clean drinking water.

- Higher Maintenance Costs: Addressing the issues with the trestle will require immediate attention and resources. Delaying repairs can lead to more extensive damage, resulting in higher costs for repairs and maintenance in the long run.

- Disruption of Water Supply: If the trestle is not repaired promptly, it could lead to disruptions in the water supply, affecting households and businesses in the area.

Solutions for Restoring Ti’s PPR-Pipe Trestle

Immediate Assessment and Inspection

The first step in addressing the issues with Ti’s PPR-pipe trestle is to conduct a thorough assessment and inspection. This process should involve:

- Structural Analysis: Engaging structural engineers to evaluate the integrity of the trestle and identify specific areas of concern.

- Material Testing: Testing the support materials for signs of corrosion or degradation, ensuring that any replacements are made with suitable materials.

- Reviewing Installation Practices: Assessing the original installation practices to determine if any changes are needed for future installations.

Repair and Rehabilitation

Once the assessment is complete, the following steps can be taken to restore the trestle:

- Reinforcement of Support Structures: Strengthening the existing support structures with additional materials or replacing corroded components to ensure stability.

- Replacement of Damaged Sections: Removing and replacing any damaged sections of the trestle to restore its functionality and integrity.

- Upgrading Installation Techniques: Implementing improved installation practices for any new components, ensuring that the trestle can support the PPR pipes effectively.

Preventive Measures for Future Maintenance

To prevent similar issues from arising in the future, it is essential to implement preventive measures, including:

- Regular Inspections: Establishing a routine inspection schedule to monitor the condition of the trestle and the PPR pipes it supports.

- Maintenance Protocols: Developing maintenance protocols that include cleaning, repairs, and upgrades to ensure the longevity of the system.

- Training for Personnel: Providing training for maintenance personnel on the proper care and management of PPR pipes and trestle structures.

- Community Awareness Programs: Educating the community about the importance of water conservation and the role of infrastructure in maintaining a reliable water supply.

Conclusion

The condition of Ti’s PPR-pipe trestle serves as a reminder of the importance of maintaining plumbing infrastructure to ensure the efficient transport of clean water. By addressing the current issues with the trestle and implementing preventive measures, local authorities can enhance the reliability of their water supply systems and reduce the risk of water loss and contamination. As communities continue to grow and demand for water increases, investing in robust infrastructure will be crucial for sustainable water management.

Frequently Asked Questions (FAQs)

1. What are PPR pipes used for?

PPR pipes are commonly used for hot and cold water supply, heating systems, irrigation, and industrial applications due to their durability and resistance to corrosion.

2. How can I identify if my PPR pipes are damaged?

Signs of damage in PPR pipes may include leaks, visible cracks, or changes in water pressure. Regular inspections can help identify potential issues before they become serious.

3. What should I do if I suspect a leak in my PPR piping system?

If you suspect a leak, it is essential to contact a qualified plumber or maintenance professional to assess the situation and perform necessary repairs.

4. How often should PPR pipes be inspected?

It is recommended to inspect PPR pipes at least once a year, or more frequently in areas with extreme weather conditions or heavy usage.

5. Are PPR pipes environmentally friendly?

Yes, PPR pipes are recyclable and have a lower environmental impact compared to traditional materials, making them a sustainable choice for plumbing systems.