Introduction

The plumbing and piping industry is constantly evolving, with new materials and technologies emerging to meet the demands of consumers and businesses alike. One of the most exciting developments in recent years is the rise of Polypropylene Random Copolymer (PPR) pipes, which offer numerous advantages over traditional piping materials. Huliot, a prominent player in the piping sector, has recently launched a retail segment range of PPR pipes, aimed at providing high-quality solutions for both residential and commercial applications. This article delves into the features and benefits of Huliot’s PPR pipes, their applications, and the significance of this new retail segment in the market.

Understanding PPR Pipes

What Are PPR Pipes?

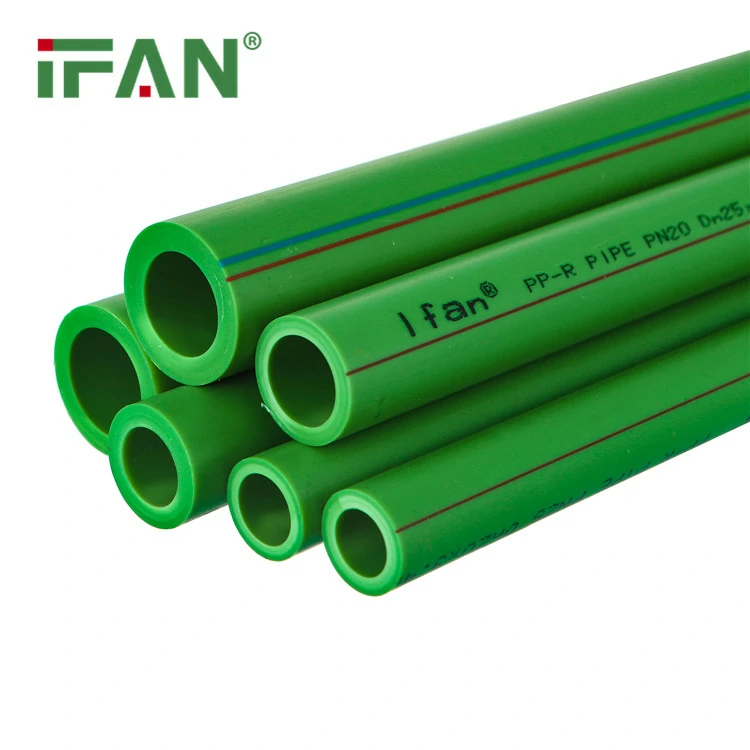

PPR pipes are manufactured from Polypropylene Random Copolymer, a thermoplastic polymer known for its strength and versatility. These pipes are designed to handle a variety of applications, including hot and cold water supply, heating systems, and industrial processes.

Key Features of PPR Pipes

- High Temperature and Pressure Resistance: PPR pipes can withstand temperatures up to 95°C (203°F) and pressures of up to 20 bars (approximately 290 psi), making them suitable for a wide range of applications.

- Corrosion Resistance: Unlike traditional metal pipes, PPR pipes do not corrode or rust, ensuring that the water transported remains clean and safe for consumption.

- Non-Toxic: PPR pipes are free from harmful chemicals and toxins, making them a safe choice for potable water applications.

- Lightweight and Easy to Handle: The lightweight nature of PPR pipes simplifies transportation and installation, which is particularly beneficial in residential and commercial projects.

- Low Maintenance: PPR pipes require minimal maintenance, reducing long-term costs associated with plumbing systems.

Huliot’s Retail Segment Range

Overview of Huliot

Huliot is a leading manufacturer of piping systems, known for its commitment to quality and innovation. With decades of experience in the industry, Huliot has established itself as a trusted name in plumbing solutions. The company’s recent launch of a retail segment range of PPR pipes is aimed at expanding its market presence and catering to the growing demand for high-quality piping solutions.

Features of Huliot’s PPR Pipe Range

- Variety of Sizes and Fittings: Huliot’s retail range includes a wide variety of PPR pipe sizes and fittings, making it easy for consumers to find the right products for their specific needs.

- Easy Installation: The PPR pipes in Huliot’s range are designed for easy installation, featuring user-friendly connections that simplify the plumbing process.

- Durability: Huliot’s PPR pipes are manufactured to the highest standards, ensuring long-lasting performance in various applications.

- Eco-Friendly Solutions: Huliot is committed to sustainability, and its PPR pipes are recyclable, contributing to a reduced environmental impact.

- Competitive Pricing: The retail segment range is competitively priced, making high-quality PPR pipes accessible to a broader audience, from DIY enthusiasts to professional plumbers.

Benefits of Huliot PPR Pipes

Enhanced Performance

Huliot’s PPR pipes provide enhanced performance due to their ability to withstand high temperatures and pressures. This makes them suitable for various applications, including hot water supply lines, heating systems, and irrigation.

Cost-Effectiveness

While the initial investment in PPR pipes may be higher than traditional materials, the long-term savings associated with reduced maintenance and increased durability make them a cost-effective choice. PPR pipes have a long lifespan and require minimal maintenance, leading to overall savings in plumbing projects.

Health and Safety

Huliot’s PPR pipes are non-toxic and free from harmful chemicals, ensuring that the water transported remains safe for consumption. This is particularly important in residential applications where clean drinking water is essential.

Versatile Applications

Huliot PPR pipes can be used in various applications, including:

- Residential Plumbing: Ideal for hot and cold water supply lines in homes, providing a safe and durable solution for residential plumbing needs.

- Commercial Plumbing: Suitable for water supply, heating systems, and irrigation in commercial settings, offering reliable performance in demanding environments.

- Industrial Applications: Huliot PPR pipes are also used in industrial processes, where their chemical resistance and durability are critical.

Environmental Sustainability

Huliot is committed to sustainability, and its PPR pipes are designed with the environment in mind. The recyclability of PPR pipes reduces waste and contributes to a more sustainable future. Additionally, the manufacturing process of PPR pipes generates fewer emissions compared to traditional materials.

Installation and Maintenance of Huliot PPR Pipes

Installation Process

Installing Huliot PPR pipes involves several key steps:

- Planning and Design: Before installation, it is essential to plan the layout of the piping system, including determining the length of the pipe needed and the location of fittings.

- Cutting and Joining: Huliot PPR pipes can be easily cut to the desired length using a pipe cutter. Heat fusion is commonly used for joining pipes, ensuring a secure, leak-proof connection.

- Testing the System: After installation, it is crucial to test the system for leaks and ensure that it can handle the required pressure. This step is vital to ensure the longevity and reliability of the water supply system.

Maintenance Requirements

Huliot PPR pipes require minimal maintenance due to their corrosion resistance and durability. Regular inspections are recommended to ensure the system remains leak-free and efficient. This low maintenance requirement is particularly advantageous for residential and commercial applications where resources may be limited.

Conclusion

Huliot’s launch of a retail segment range of PPR pipes represents a significant advancement in the plumbing industry. With their numerous advantages, including durability, safety, and cost-effectiveness, Huliot PPR pipes are poised to meet the growing demand for high-quality piping solutions. As consumers increasingly seek reliable and eco-friendly options for their plumbing needs, Huliot is well-positioned to lead the market with its innovative PPR pipe offerings.

Frequently Asked Questions (FAQs)

1. What are PPR pipes used for?

PPR pipes are used for a variety of applications, including hot and cold water supply, heating systems, irrigation, and industrial processes.

2. How do Huliot PPR pipes compare to traditional piping materials?

Huliot PPR pipes offer several advantages over traditional materials, including corrosion resistance, lower maintenance costs, and a lightweight design that simplifies installation.

3. Are Huliot PPR pipes safe for drinking water?

Yes, Huliot PPR pipes are non-toxic and free from harmful chemicals, making them a safe choice for transporting drinking water.

4. What is the installation process for Huliot PPR pipes?

The installation process involves planning the layout, cutting the pipes to the desired length, joining them using heat fusion, and testing the system for leaks.

5. Do Huliot PPR pipes require maintenance?

Huliot PPR pipes require minimal maintenance due to their durability and corrosion resistance. Regular inspections are recommended to ensure the system remains efficient and leak-free.