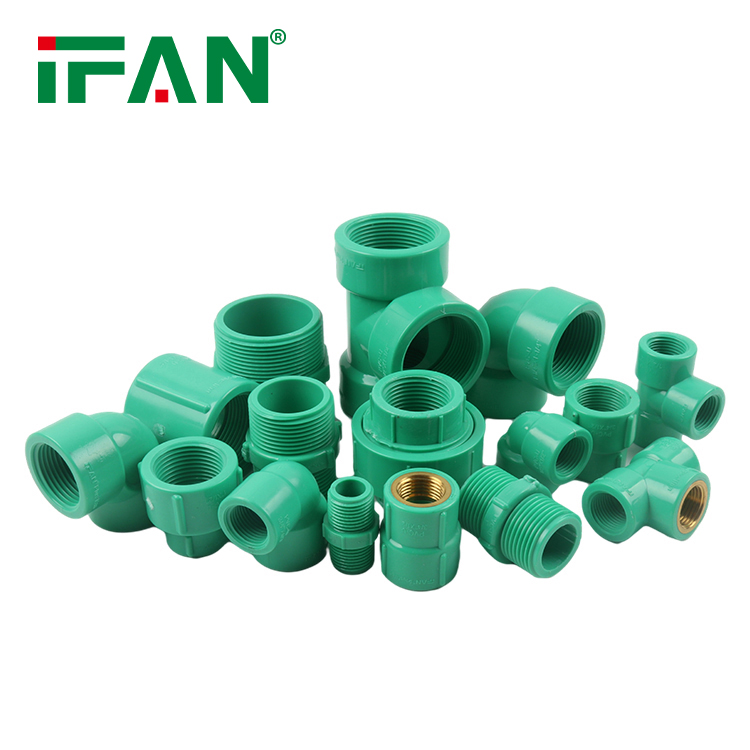

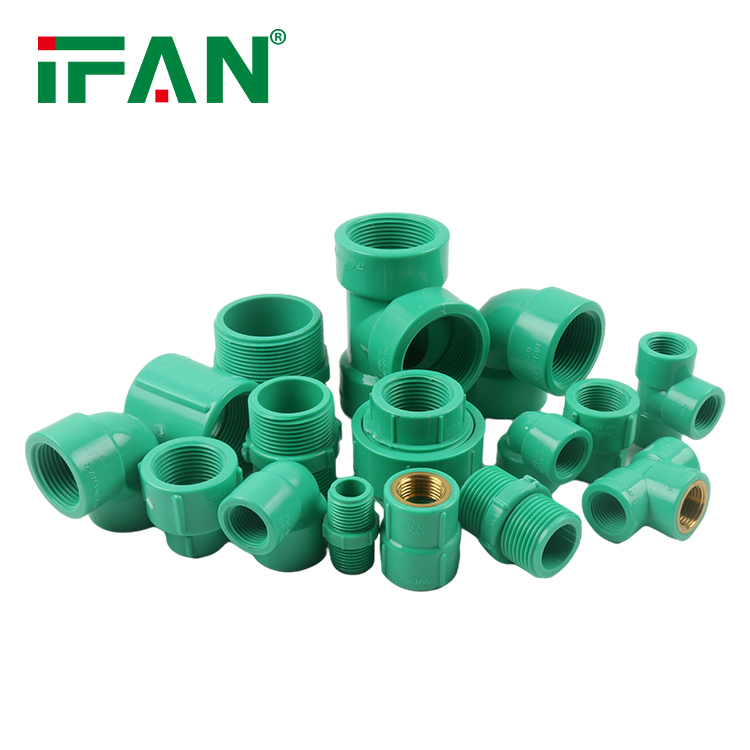

Description

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

Sealing uPVC fittings correctly is crucial for preventing leaks in plumbing systems. Proper sealing ensures that joints are secure and fluid flow remains uninterrupted, thereby enhancing the longevity and efficiency of the system. This article outlines the essential steps and best practices for effectively sealing uPVC fittings.

Understanding uPVC Fittings

uPVC fittings are widely used in plumbing due to their durability, resistance to corrosion, and ease of installation. Common types include elbows, tees, couplers, reducers, and valves. Each fitting connects segments of pipe to create a complete plumbing system. However, improper sealing can lead to leaks, which may cause water damage, reduce system efficiency, and necessitate costly repairs. Understanding the fittings’ construction and the sealing process is vital for successful installation.

Preparing the Fittings and Pipes

Before sealing uPVC fittings, it’s essential to prepare both the fittings and the pipes adequately. Start by ensuring that the surfaces are clean and free from dirt, dust, and debris. Use a damp cloth to wipe down the areas where the fittings will connect. If there are any burrs or rough edges on the pipes, smooth them out using a fine file or sandpaper. Proper preparation is critical because contaminants can interfere with the sealant’s adhesion, leading to potential leaks.

Choosing the Right Sealant

Selecting the appropriate sealant is key to ensuring a leak-free installation. For uPVC fittings, solvent cement is the most common choice. This type of cement chemically fuses the pipes and fittings together, creating a strong bond. Make sure to choose a solvent cement that is specifically designed for uPVC materials. Always read the manufacturer’s instructions regarding drying times and application methods, as this information will vary between products. Using the right sealant not only enhances the integrity of the joint but also ensures it can withstand the pressures of the plumbing system.

Applying the Sealant Correctly

Once you have prepared the fittings and selected the right sealant, it’s time to apply it. Begin by applying a liberal amount of solvent cement to both the fitting and the pipe. Use a brush or applicator provided with the sealant to ensure an even coat. Insert the pipe into the fitting with a twisting motion to ensure that the cement spreads evenly across the connection. After insertion, hold the joint in place for about 30 seconds to allow the cement to set slightly. Avoid moving the fitting until the cement has cured completely, as movement can compromise the seal.

Allowing for Proper Curing

After applying the sealant, allowing sufficient curing time is crucial for a strong, leak-free bond. The curing time can vary depending on the type of solvent cement used, environmental conditions, and the size of the fittings. Generally, it is recommended to wait at least 24 hours before testing the system under pressure. During this period, avoid exposing the sealed joints to water or physical stress. Ensuring that the sealant cures properly maximizes its performance and reduces the risk of future leaks.

Final Inspection and Testing

Once the curing period is complete, perform a thorough inspection of the installed fittings. Look for any signs of excess sealant or irregularities in the joints. If possible, conduct a pressure test to check for leaks. This can be done by filling the system with water and observing for any dampness or dripping around the fittings. If leaks are detected, the affected areas may need to be disassembled and resealed. A thorough final inspection ensures that the plumbing system operates reliably, providing peace of mind and preventing costly repairs down the line.

Conclusion

Properly sealing uPVC fittings is essential for preventing leaks and maintaining a functional plumbing system. By understanding the components involved, preparing the surfaces, choosing the right sealant, applying it correctly, and allowing for adequate curing, you can ensure a secure and long-lasting connection. Following these best practices will not only enhance the reliability of your plumbing system but also save you time and money in the long run. With careful attention to detail, you can enjoy a leak-free environment in your home or business.

Related products