I. Introduction: The Rise of HDPE in Fluid Connectivity

In the world of fluid systems, HDPE (High-Density Polyethylene) fittings are emerging as the go-to choice for their unparalleled durability, versatility, and environmental friendliness. Today, we delve into the latest news surrounding HDPE fittings, showcasing their revolutionary impact on various industries.

II. The Strength of HDPE: Durable Solutions for Demanding Applications

Unmatched Durability – HDPE fittings are renowned for their exceptional strength and resilience, capable of withstanding harsh environments and high-pressure conditions. This makes them ideal for use in water supply systems, irrigation networks, and even gas pipelines.

Corrosion-Resistant – Unlike metal fittings, HDPE fittings are completely corrosion-proof, eliminating the need for regular maintenance and reducing the risk of leaks. This not only saves time and money but also ensures the safety of the fluid system.

III. Environmental Advantages: Green Solutions for a Sustainable Future

Eco-Friendly Material – HDPE is a highly recyclable material, and the use of HDPE fittings promotes a circular economy. By choosing HDPE fittings, industries can reduce their carbon footprint and contribute to environmental sustainability.

Long Lifespan – The durability of HDPE fittings translates into a longer lifespan, reducing the need for frequent replacements. This, in turn, minimizes waste generation and the associated environmental impacts.

IV. Versatility in Design: Custom Solutions for Diverse Needs

Flexible Configurations – HDPE fittings come in a wide range of sizes, shapes, and configurations, catering to diverse installation requirements. From simple couplings to complex branch fittings, HDPE offers customizable solutions for every application.

Easy Installation – HDPE fittings are designed for ease of installation, reducing labor costs and minimizing downtime. Their lightweight nature and flexibility make them ideal for tight spaces and challenging installations.

V. Industry Applications: Transforming Fluid Systems Across Sectors

Water Infrastructure – HDPE fittings are widely used in water supply systems, irrigation networks, and wastewater treatment facilities due to their corrosion resistance and durability.

Oil & Gas – In the oil and gas industry, HDPE fittings are employed in pipelines, wellheads, and other critical infrastructure due to their ability to withstand high pressures and harsh environments.

Industrial & Commercial – From chemical processing plants to commercial buildings, HDPE fittings offer reliable and cost-effective solutions for fluid transfer and distribution.

VI. Market Trends: The Future of HDPE Fittings

Growing Demand – As the world becomes increasingly focused on sustainability and efficiency, the demand for HDPE fittings is on the rise. Industries are turning to HDPE for its eco-friendly properties and long-term cost savings.

Innovative Developments – Manufacturers are continuously innovating to improve the performance and functionality of HDPE fittings. New technologies, such as reinforced materials and advanced joining systems, are enhancing the reliability and versatility of HDPE fittings.

VII. Conclusion: The Future is HDPE

In conclusion, HDPE fittings are revolutionizing fluid systems worldwide with their durability, versatility, and environmental advantages. As the demand for sustainable and efficient solutions grows, HDPE fittings are poised to play an increasingly important role in various industries. By embracing HDPE fittings, businesses can enhance their fluid systems’ performance, reduce costs, and contribute to a greener future.

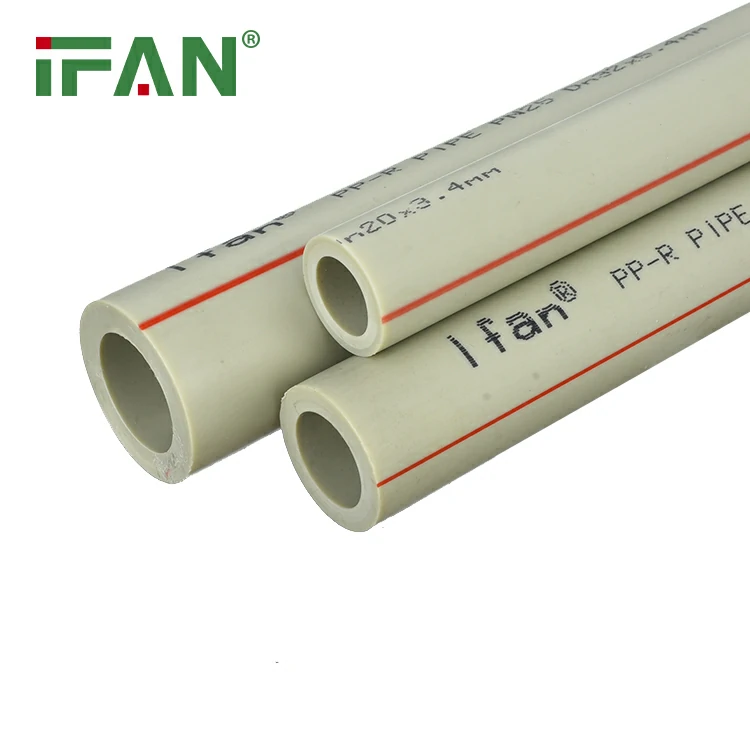

IFAN

IFAN factory started in 1993. And IFAN has workshop 120000 square meter with 610 staff. IFAN can design and produce all plumbing pipe and fitting include PPR,PVC,CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting ,brass fitting, brass ball valve ,heating system , gas system , sanitary faucets and hose, In the past 30 Years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory use best materials to produce high quality pipe and fittings with automatic production line and high tech quality control machines. The most important,IFAN can guarantee that all pipes and fittings manufactured by IFAN are qualified. more information pls feel free contact us facebook